Installation |

15

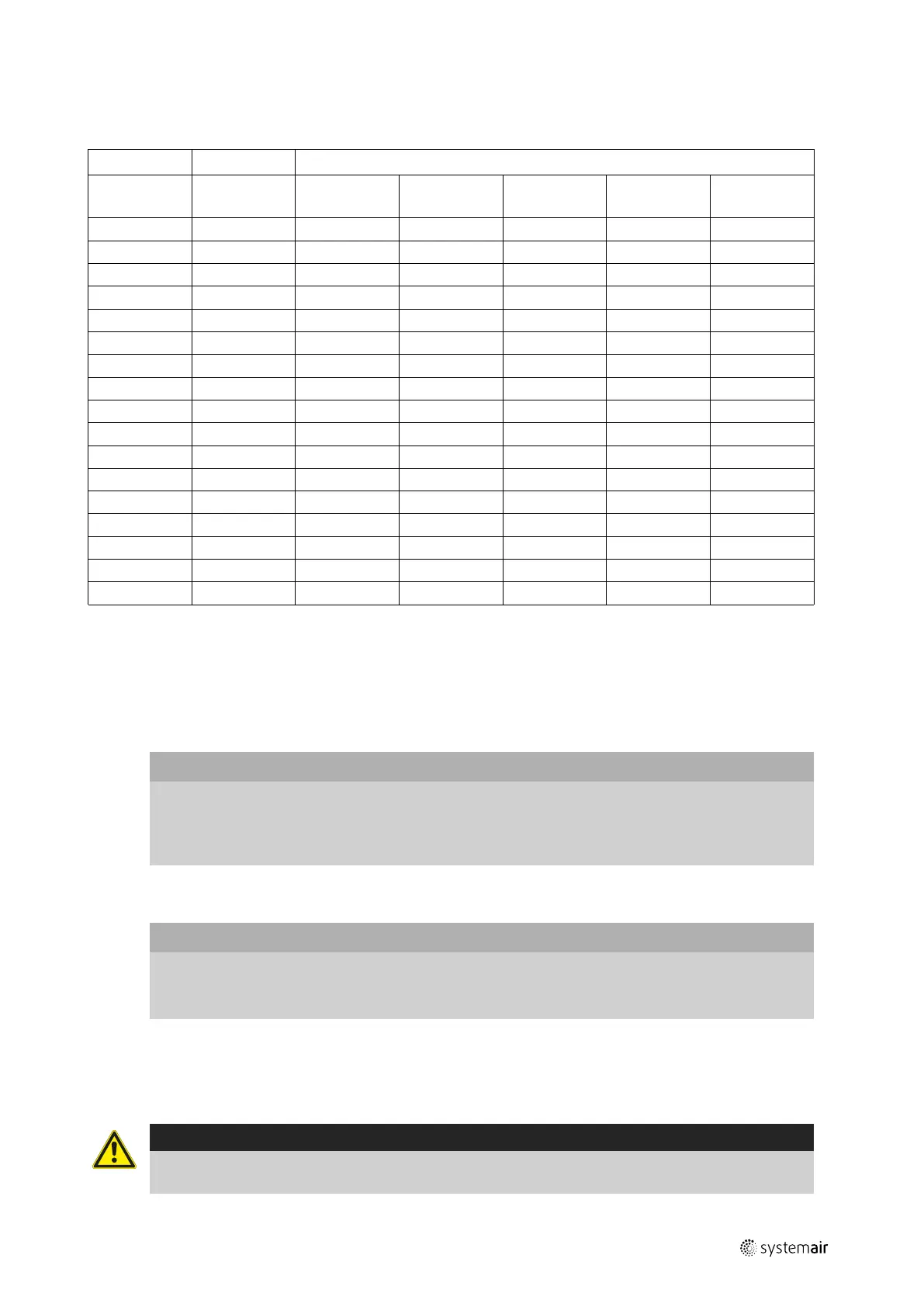

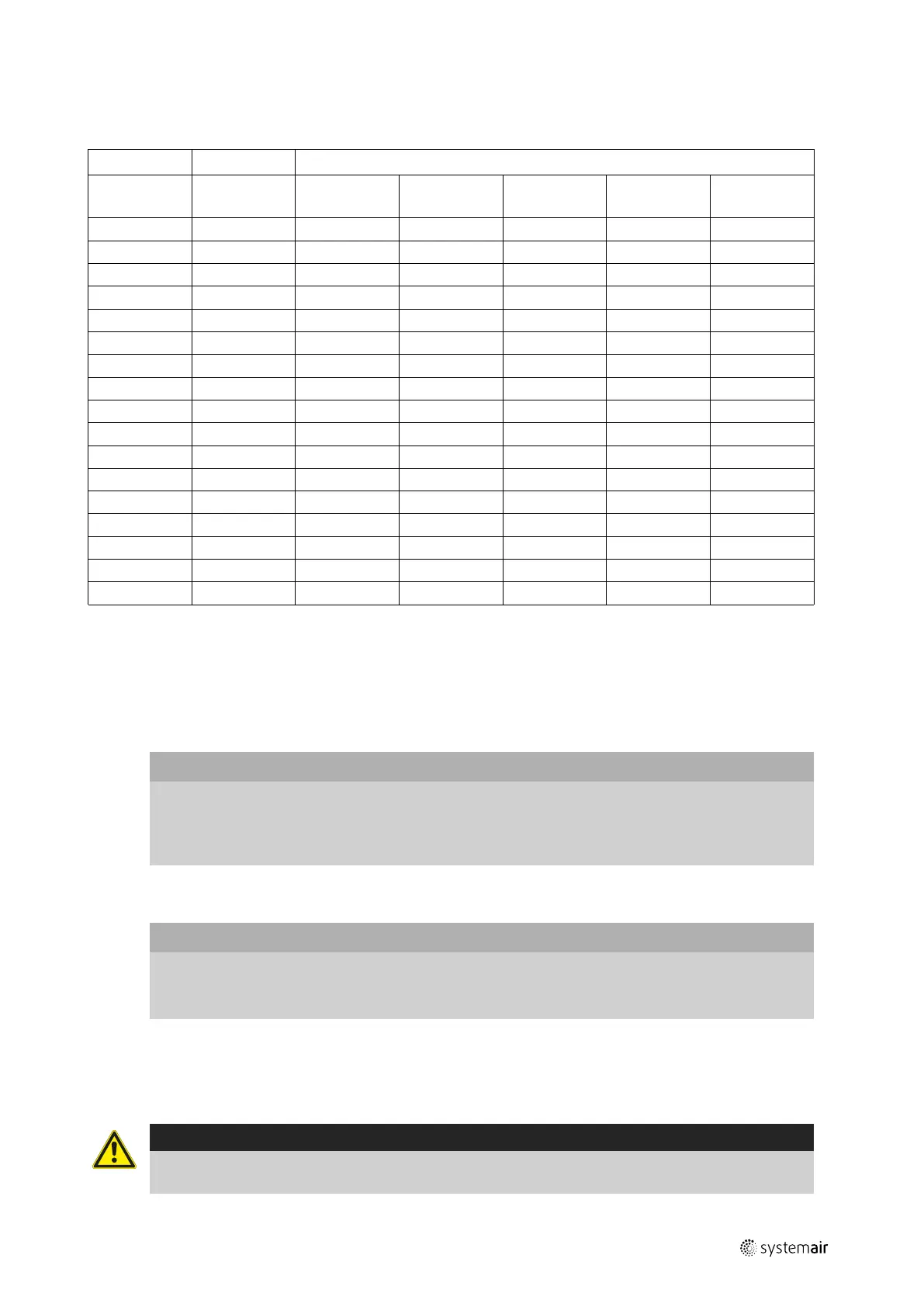

7.3 Tightening torques of screw-type connections according to DIN 13

Table 9 Tightening torques according to DIN 13

Screw size

Key width

Thread

SW

6.9 M [Nm] 8.8 M [Nm] 10.9 M [Nm] 12.9 M [Nm] Aluminium

hubs [Nm]

M6 10 9 10 15 18 8

M7 11+12 14 17 25 28 14

M8 13+14 22 26 35 42 21

M10 15+17 42 50 71 85 40

M12 19+21 74 87 123 147 70

M14 22+23 117 138 194 235 110

M16 24+26 178 210 299 358 159

M18 27 245 289 412 490 231

M20 30 348 412 579 696 330

M22 32 471 559 785 941 447

M24 36 598 711 1000 1196 569

M27 41 888 1049 1481 1775 839

M30 46 1206 1422 2010 2403 1138

M33 50 1628 1932 2716 3266 1546

M36 55 2099 2481 3491 4197 1985

M39 60 2716 3226 4531 5443 2581

M42 65 3364 3991 5609 6727 3193

7.4 Mounting feet

Depending on the kind of fan and the construction size, mounting feet are either included in the delivery or available as

accessories. If you are not sure, check the online catalogue or contact Systemair.

7.5 Avoid resonance frequencies

Important

Risk of damage to the fan due to resonance frequencies

♦ The minimum fan speed should be double the resonance frequency of the anti-vibration system

(vibration dampers).

♦ To avoid resonance frequencies, see 8.5 Frequency converter (if used), page 23.

7.5.1 Vibration dampers

Important

Risk of damage to the fan due to incorrect vibration dampers

♦ Use the vibration dampers suitable for the respective weight.

♦ Use the vibration dampers with fire resistance classes that match the respective application.

7.6 Lifting and positioning

The weight of the fan units varies depending on the motor size and accessories. As a result, the fan unit can also be

very bulky and heavy. You can find precise information on the name plate or the data sheet.

Caution

Risk of parts falling down

♦ When fitting the fan, pay attention to its weight and the weight of the components.

| 003

Loading...

Loading...