4

|

Description

Storage more than 12 months

♦ We recommend an inspection by the after-sales service of Systemair before commissioning.

Test the motor windings:

♦ Measure the insulation resistance of each motor winding against grounding at 500 V DC. The insulation resistance

must be > 10 mΩ.

Measures for an insulation resistance < 10 mΩ:

1. If the motor has drain plugs, remove them to allow any moisture to drain and replace them when the motor windings

are suitably dry.

2. Dry the motor in a warm dry airflow (typically 40 degrees Celsius).

3. Measure the insulation resistance of each motor winding against grouding at 500 V DC.

4. Repeat the aforementioned steps until the measurement outcome > 10 mΩ.

Test the motor:

♦ Connect an ammeter to each phase of the motor.

♦ Switch the fan on and check the current consumption.

♦ Compare the current consumption with the nominal consumption on the name plate.

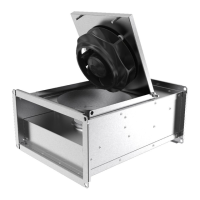

5 Description

5.1 General

• The fan conveys air in an axial direction from the intake side via the electric motor to the outlet side. (except AXCBF).

• The electrical connection is made through a terminal box installed on the outside of the housing (except AXCBF).

5.1.1 Sensors (optional)

Sensors can be connected to the fan to monitor the roller bearings and for vibration monitoring.

5.1.2 Standstill heating (optional)

The standstill heating starts when the motor switches off and vice versa.

5.1.3 Technical data of the fan

The technical data of the fan can be seen on the name plate or the data sheet.

5.1.4 Motor data

The motor data can be found on the name plate of the motor or in the technical documents of the motor manufacturer.

| 003

Loading...

Loading...