OPERATING PROCEDURES

6-17

PH61 Peristaltic Pump

Operating Procedures

6

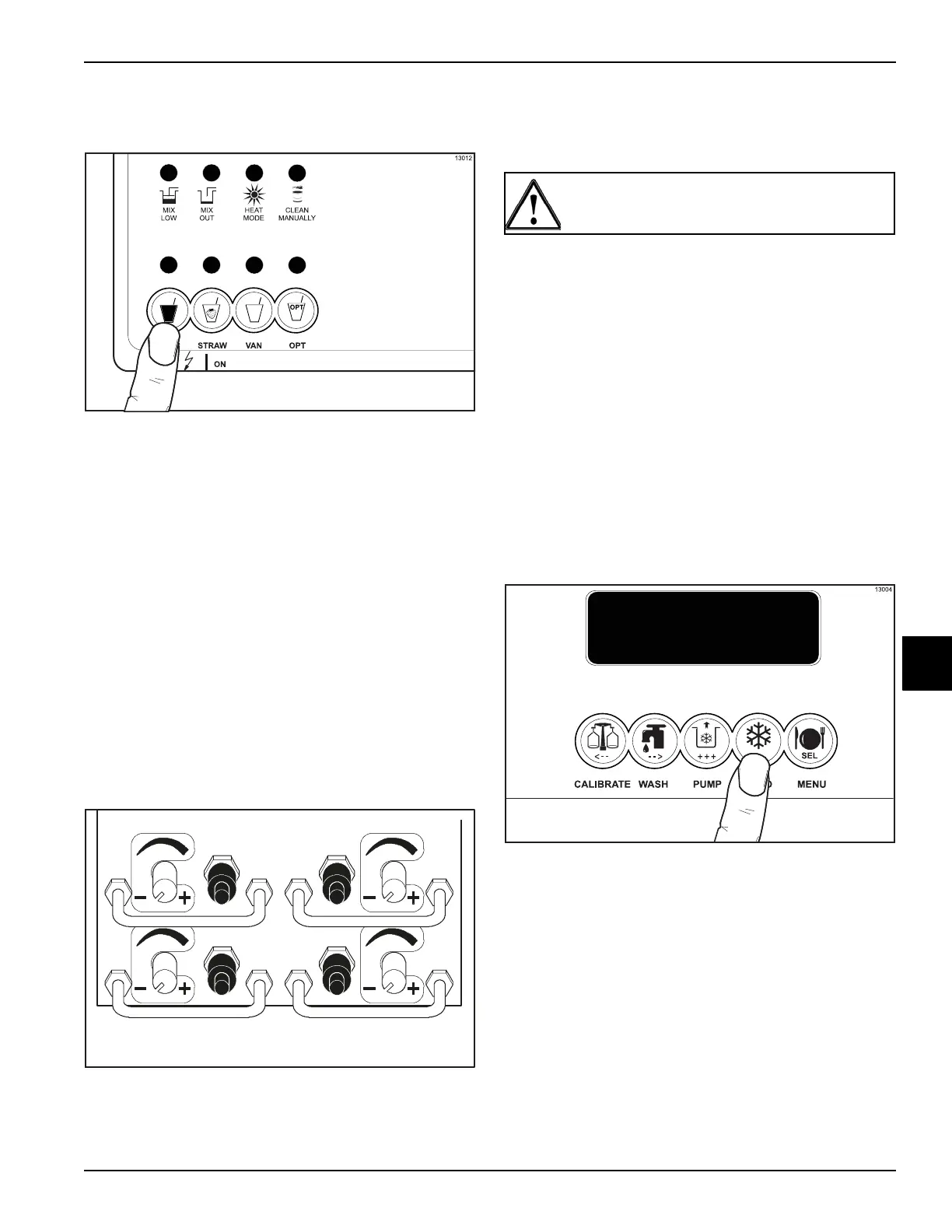

7. Push the corresponding syrup flavor key. The light

should be illuminated. (

See Figure 6-63.)

Figure 6-63

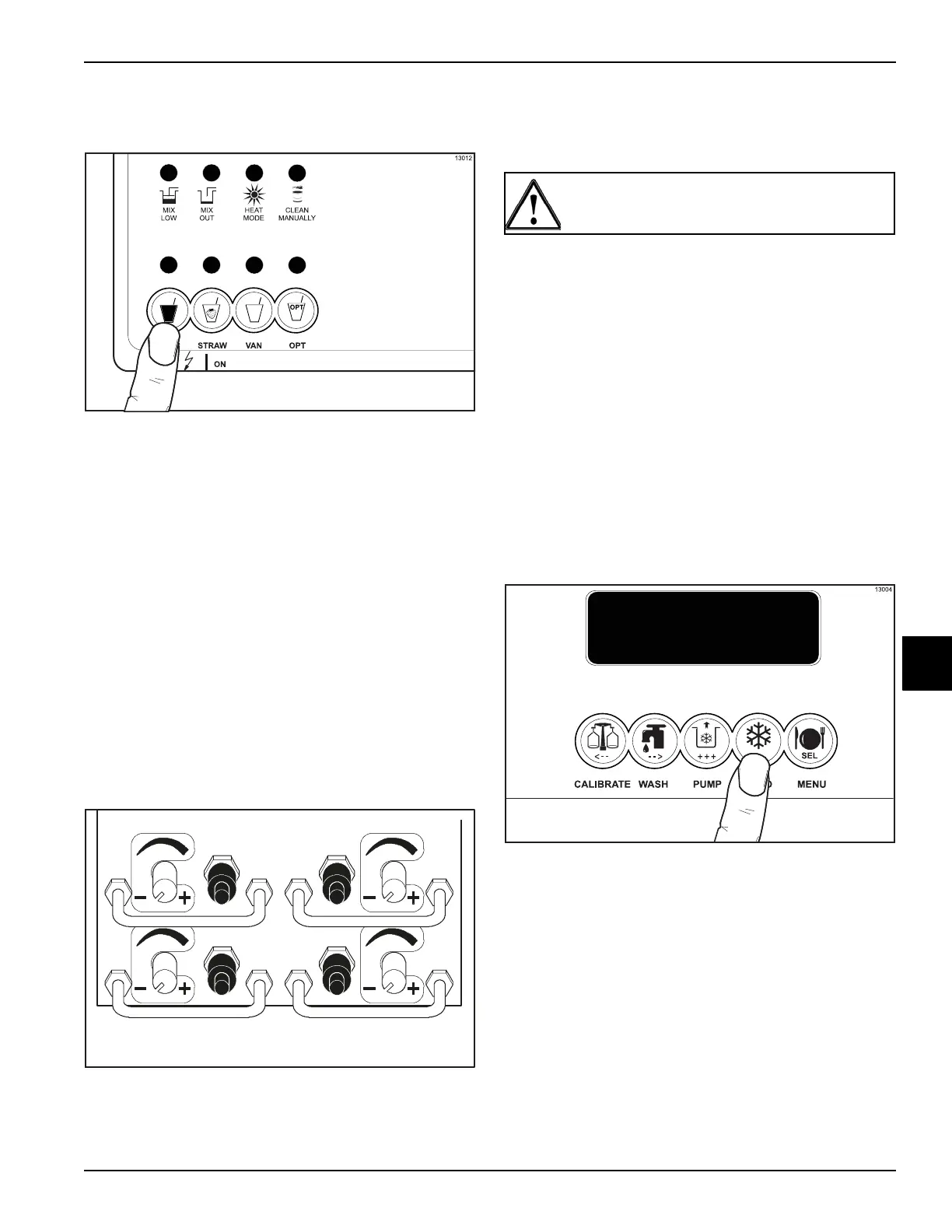

8. Press the CAL key. A message will appear on the

LCD.

9. Press the WASH key to start the pump and to prime

the syrup line.

10. When a steady stream of syrup is flowing from the

syrup valve, and all the air has been removed from

the syrup line, press the CAL key again to stop the

pump.

Note: There is a black prime button mounted at the

top of the syrup cabinet (one per flavor), which

speeds up the priming process. After the WASH key

has been pressed, press and hold the corresponding

black prime button in the syrup cabinet until the syrup

flow out of the line is consistent and all air bubbles

have been removed from the line. (See Figure 6-64.)

Figure 6-64

Closing Procedures

Important! This procedure must be completed every 2

weeks!

To disassemble the PH61, the following items will be

needed:

• Two cleaning and sanitizing pails

• Cleaning brushes (provided with machine)

• Approved cleaning/sanitizing solution with

active chlorine concentrate of 100 to 200 ppm

• Clean, sanitized towels

• Parts trays

Draining Product From the Freezing

Cylinder

1. Cancel automatic operation by pressing the AUTO

key. (

See Figure 6-65.)

Figure 6-65

2. Remove the shake cup holder. Set it aside for

cleaning later with all parts.

3. Remove the hopper cover and agitator. Take these

parts to the sink to wash, rinse, and sanitize.

ALWAYS FOLLOW LOCAL HEALTH CODES.

Loading...

Loading...