Now you can use the MONITOR head

as

a

test

instrument to check and adjust the record circuits.

Almost

al1 of the following steps involve recording

a

tone on

a

tape and reading the playback output of the

recorder. YOU WON'T ALTER THE PLAYBACK

CONTROLS. They are now

al1

set. You will make al1

necessary adjustments by trimming the record electron-

ICS.

This way, you can be sure that the recordings you

make, no matter what brand of tape you use

(the

brand of tape becomes part of the test procedure when

you record your test tones on

it),

will playback

properl y on any 80-8.

The alignment tape

can be put away. Before storing,

the tape should be played

al1 the way from front to

back (not fast wound), and stored

tails out, so it will

last

longer. Even if you decide not to attempt any

major maintenance yourself, we strongly suggest you

purchase an alignment tape. An

occasiona1 playing will

tell you when you

need to call the"doctor".

It's

good

insurance to know the truth.

The record adjustments

begin with the INPUT MONIT

LEVEL trim of the 80-8.

The INPUT MONIT LEVEL

controls the meter reading of the signal

as

it

arrives

at

the electronics (before

it

is

recorded). You must be

sure you are sending the right amount of signal in

before you

can adjust record levels

ad

equalization

controls.

Connect the reference level, or signal generator to track

1 input on the 80-8. The correct level

is

-10 dB

(0.3 V).

The frequency to use

is

1 kHz. Rotate the front panel

knob to the

"2

o'clock" position. It's

a

good idea to

mark

it.

Check the OUTPUT SELECT. Make sure you

have the button marked INPUT depressed. If you get a

reading, use trim pot

#6

R107,

22

kOhms, INPUT

MONIT LEVEL, and adjust the meter to

read

O

VU.

As

always, repeat this check on al1 8 tracks of the 80-8.

Plugging and unplugging test equipment

can be tedious.

You

can save some time by doing

a

reference check on

your mixer.

If you know that your console meter reads

O

VU accurately (check

it

with the VTVM), you can

assign the reference oscillator signals to the 80-8

through the mixer connections to the inputs. Assign,

read, adjust: next track, assign, read adjust.

.

.

no need

t0

pull plugs.

ABOUT THE BIAS:

At this point in the adjustment procedure we'll stop

for

a

time and talk about

a

major section of the

recorder electronics. The Bias Oscillator and

its

related

circuitry. The Bias Oscillator produces

a

very high

frequency signal that does two big jobs in the80-8.

It

supplies the 100 kHz (one hundred thousand cycles per

second) frequency to the Bias Amplifiers in the 80-8.

There is a Bias Amplifier on every card, one for each

track. The Bias Amplifier provides power for the

erase

head and bias signal for the record head. Erasure

is

easy

to explain, so we'll tackle that subject first. A lot of

power

is

used to remove al1 signal from the tape just

prior to

its

being recorded. The erase head has

a

rather

large gap and completely cleans off any magnetic field

on the tape

by

brute force. No new signal

is

recorded

by this head. The gap

is

much too large to be effective

as

a

recording device.

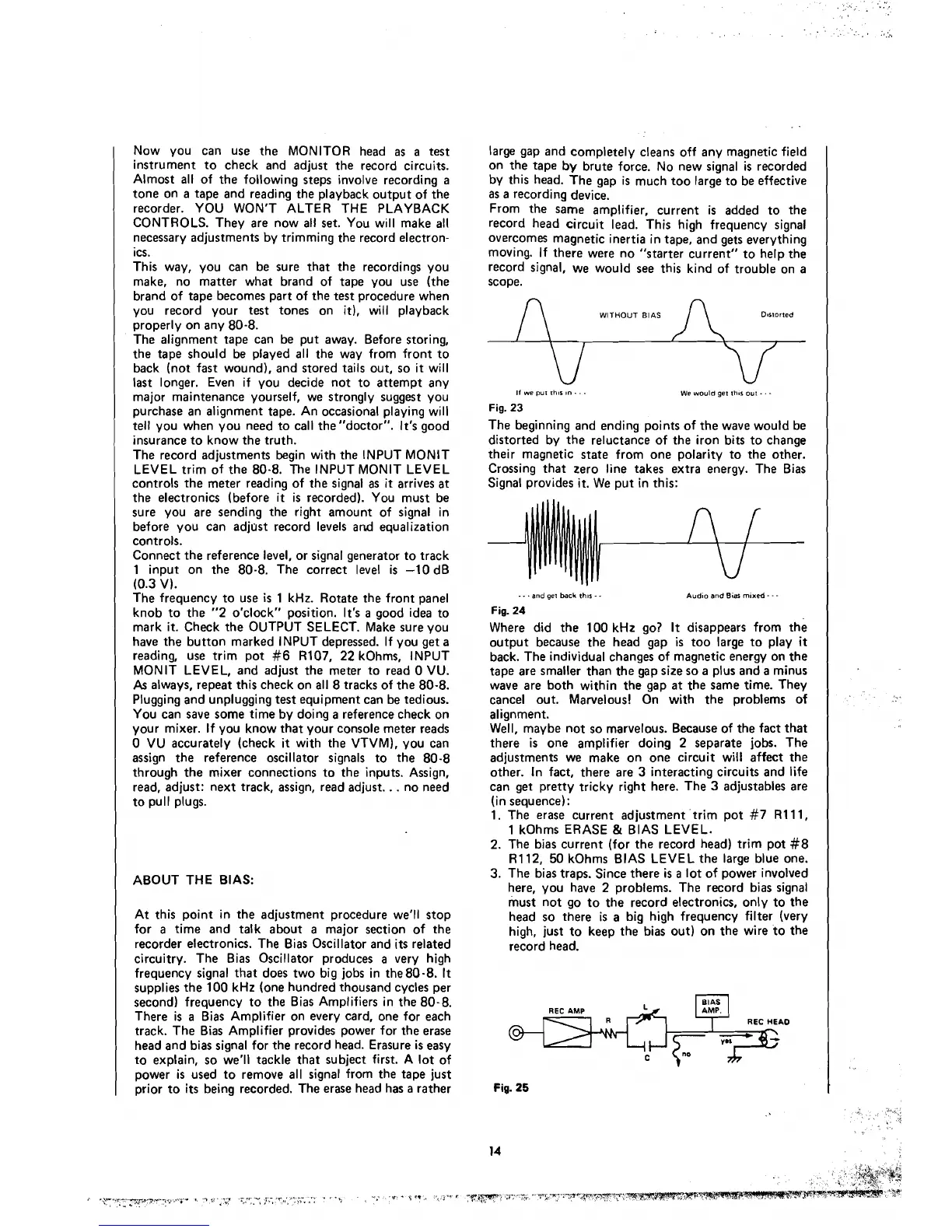

From the same amplifier, current

is

added to the

record head circuit

lead. This high frequency signal

overcomes magnetic inertia in tape, and gets everything

moving.

If there were no "starter current" to help the

record signal, we would see this kind of trouble on a

scope.

WITHOUT

BIAS D~rrorted

If

we

pul rh~s

in.

-

.

Fig.

23

We

would get ihir oui

The beginning and ending points of the wave would be

distorted by the reluctance of the iron bits to change

their magnetic state from one polarity to the other.

Crossing that zero Iine takes extra energy. The Bias

Signal provides

it.

We put in this:

- -

.

and

gei

back

thir

-

.

Audio and

Bis

rnixed

- - -

Fig.

24

Where did the 100 kHz go?

It

disappears from the

output because the head gap

is

too large to play

it

back. The individua1 changes of magnetic energy on the

tape are

smaller than the gap size so a plus and a minus

wave are both within the gap

at

the same time. They

cancel out.

Mawelous! On with the problems of

alignment.

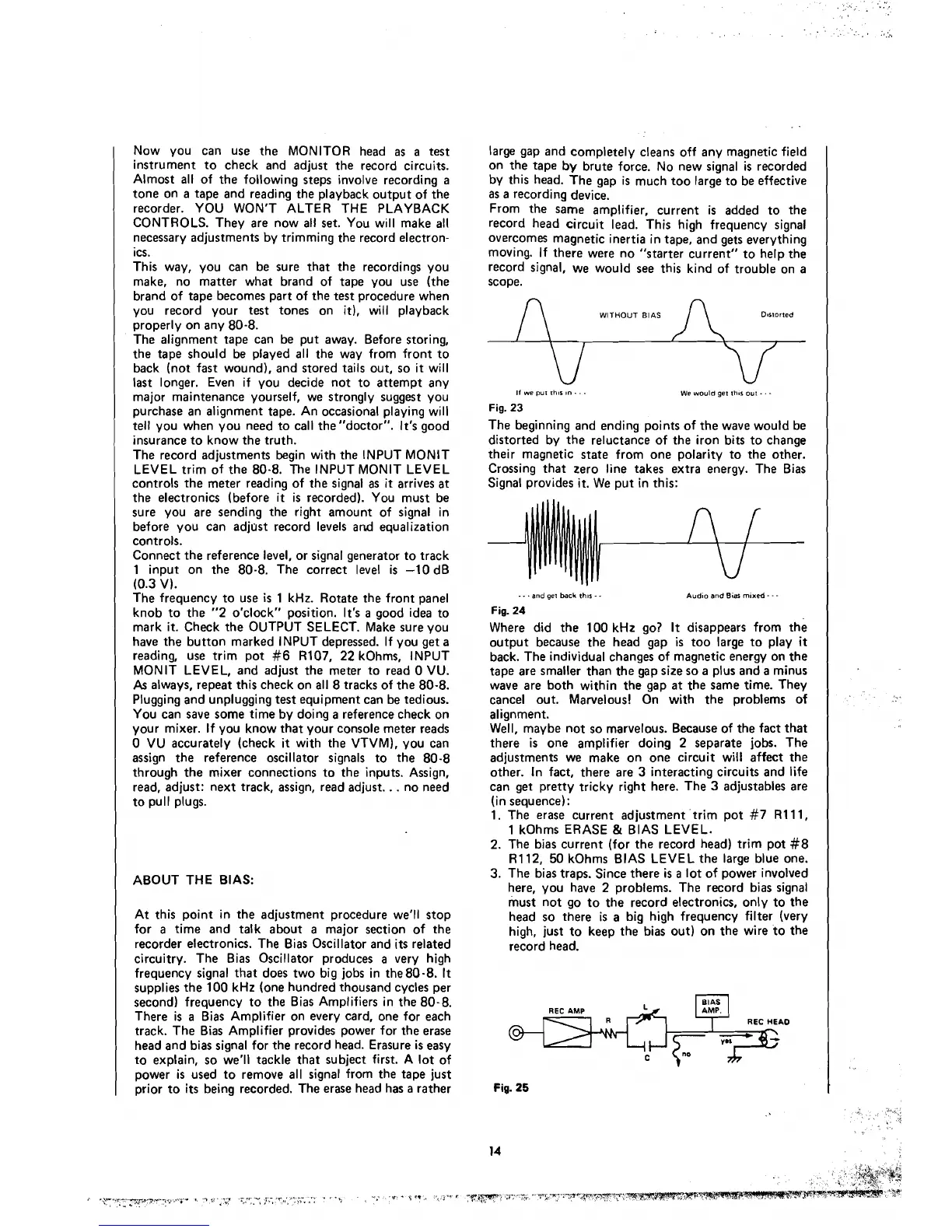

Well, maybe not so marvelous. Because of the fact that

there

is

one amplifier doing

2

separate jobs. The

adjustments we make on one circuit

wili affect the

other. In fact, there are 3 interacting circuits and life

can get pretty tricky right here. The 3 adjustables are

(in sequence):

1. The

erase current adjustment trim pot #7 R111,

1 k0hms ERASE

&

BIAS LEVEL.

2.

The bias current (for the record head) trim pot #8

R112, 50 kOhms BIAS LEVEL the large blue one.

3. The bias traps.

Since there

is

a

lot of power involved

here, you

have

2

problems. The record bias signal

must not go to the record electronics, only to the

head so there

is

a big high frequency filter (very

high, just

to keep the bias out) on the wire to the

record head.

I

BIAS

I

I

7

REC

HEAO

I

REC

AMP

l

Fig.

25

t

Loading...

Loading...