Degaussing (Demagneti~in~)

A

little stray magnetism goes a long way.

A

long way

towards making trouble for your tapes.

It only takes a

small amount

(.2

gauss) to cause trouble on the record

head and playing 10 rolls of tape will put about that much

charge on the heads and other ferrous parts of the tape

path.

A

little more than that

(.7

gauss) will start to erase

high frequency signal on previously recorded tapes.

Demagnetize the whole tape path, including the tips of

the tension arms every six fully played 10%" reels. This

is

a fair "rule of thumb" even though

it

may be a bit hard to

keep track of. Fast motion isn't as significant to the

heads, so we don't give an hourly reference. It's the

recordlplay time that counts.

Degaussing is always

done with the recorder turned off. If

you try it with the electronics on, the 60 cycle current

pulses produced by the degausser will look

just like 60 Hz

audio to the heads, at about 10,000 VU and will seriously

damage the electronics

andlor .the meters. Turn off the

machine, turn on the degausser at least

3

feet away from

the recorder. Move slowly in to the tape path. Move the

degausser slowly up and down in close proximity to

al1

ferrous parts and, slowly move away to at least

3

feet

before turning off.

It's

a good idea to concentrate when you are degaussing.

Don't try to hold a conversation or think of anything else

but the job you are doing. If the degausser

is

turned off or

on by accident while

it

is

near the heads, you may put a

permanent charge on them that no amount of careful

degaussing will

remove

-

head replacement time again,

we're sorry to say. Make

sure you are wide awake for this

procedure.

A

clean and properly demagnetized tape recorder will

maintain its performance without any other attention for

quite some time. Even if

it

does drift as a recorder, it

won't ruin previously

recorded material, and getting

it

back in good shape will not be too difficult. To make

electronic adjustments, you

need test gear, so let's go over

what's necessary.

1)

Alignment Tapes

You

need one for each speed that the recorder operates

at. For the 80-8 the specs are:

Reference fluxivity: 250 nWb/m

Equalization standard: IEC

15 ips

m

&

35ps

(See page 10; Test Tapes)

These test tapes are made by

severa1 companies, but

there are many different tape specs. Be

sure you have

the right one.

Lets's talk about each

sDec separately.

Reference Fluxivity

-

How much magnetic energy

is

necessary on the tape to make the meter read

"O

VU"

in playback? This

is

the "benchmark" or standard you

tune your playback electronics to. 250 nano Webers

per meter

is

the correct value for the 80-8. If a lower or

higher "Reference

Fluxivity"

is

used to set up the

playback,

al1 your other measurements will be off.

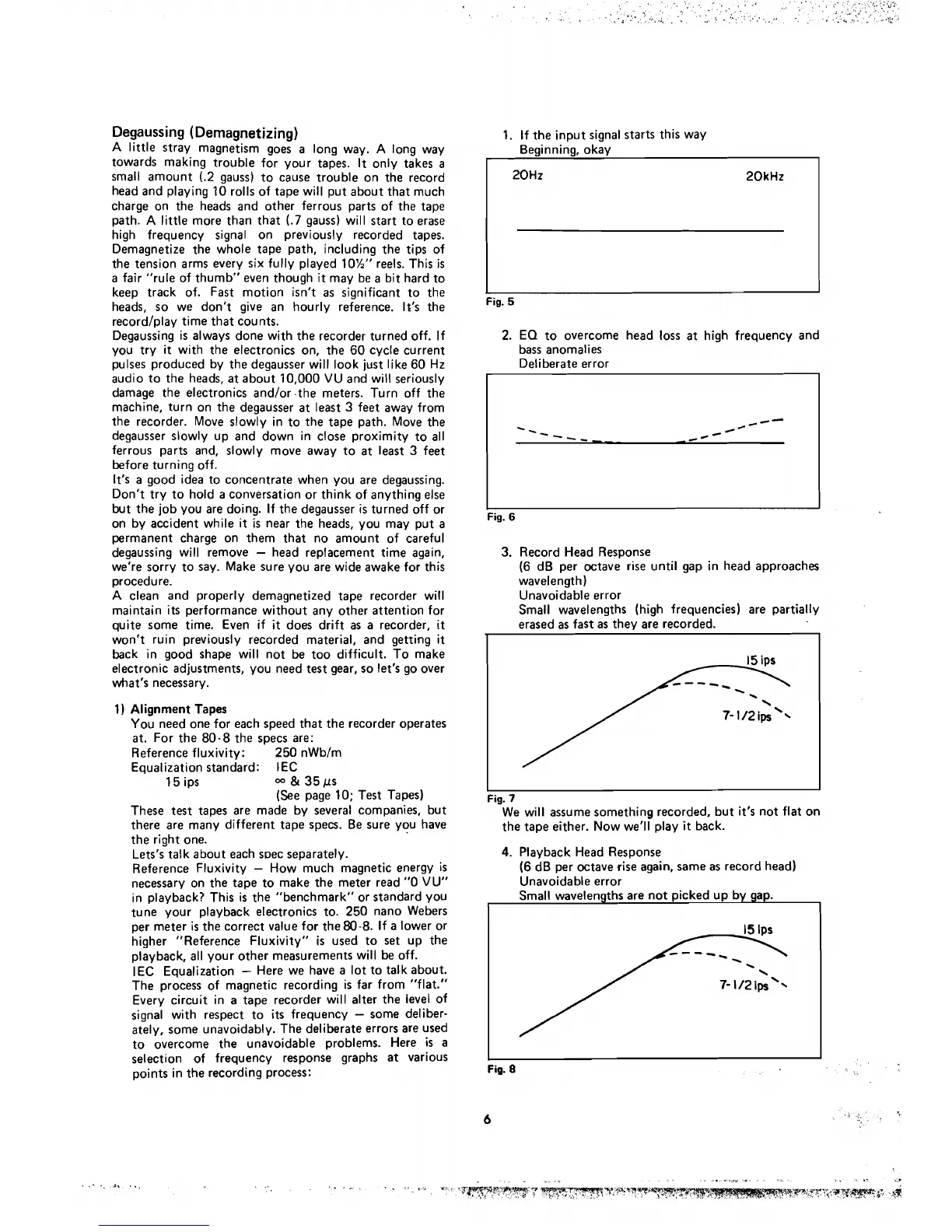

IEC

Equalization

-

Here we have a lot to talk about.

The process of magnetic recording is far from "flat."

Every circuit in a tape recorder will alter the

leve1 of

signal with respect

to

its

frequency

-

some deliber-

ately, some unavoidably. The deliberate errors are used

to overcome the unavoidable problems. Here

is

a

selection of frequency response graphs at various

points in the recording process:

1.

If the input signal starts this way

Beginning, okay

20Hz 20kHz

Fig.

5

2.

EQ to overcome head loss at high frequency and

bass anomalies

Deliberate error

l

I

Fig.

6

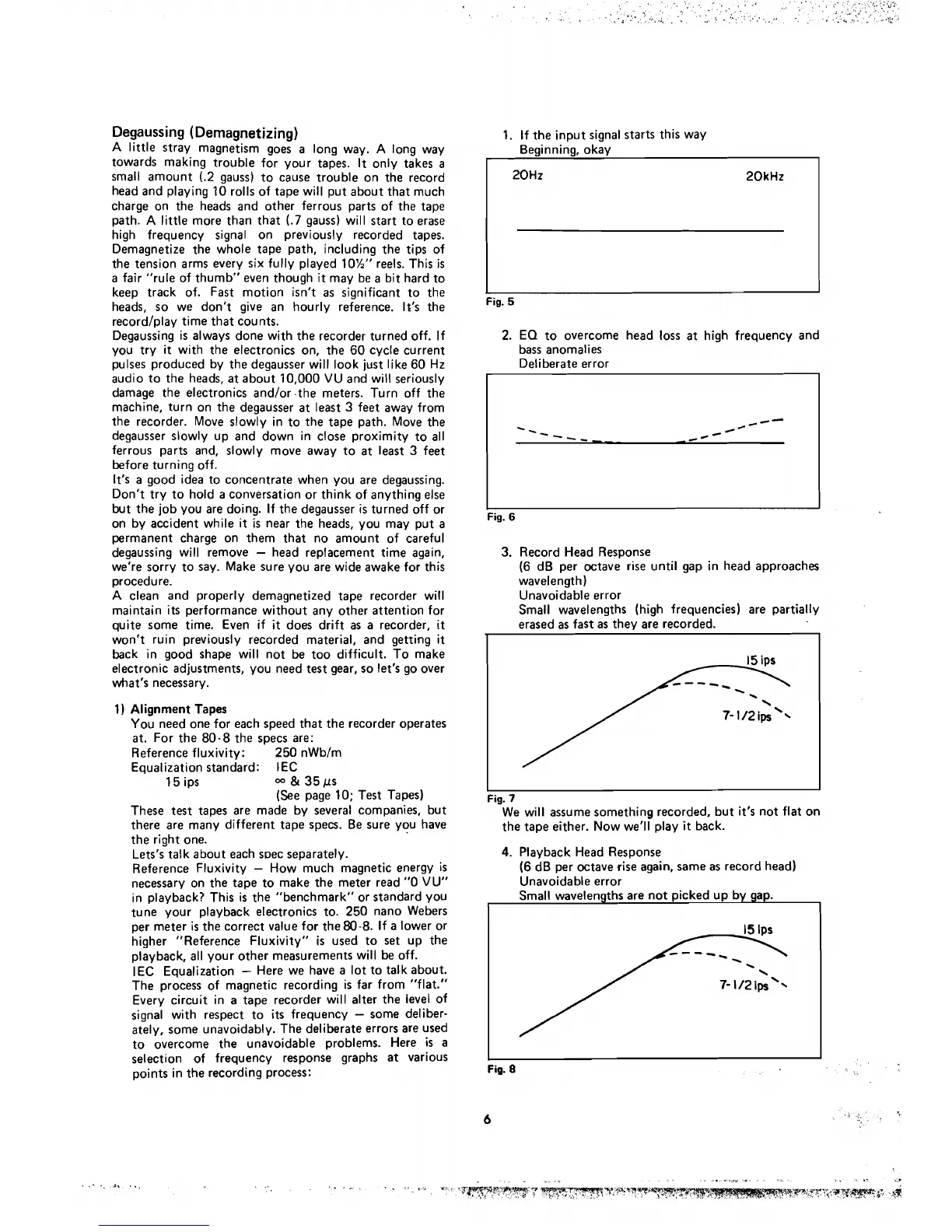

3.

Record Head Response

(6

dB per octave rise until gap in head approaches

wavelength)

Unavoidable error

Small wavelengths (high frequencies) are partially

erased as fast as they are recorded.

Fig.

7

We will assume something recorded, but it's not flat on

the tape either. Now

we'll play

it

back.

4.

Playback Head Response

(6

dB per octave rise again, same as record head)

Unavoidable error

Small wavelengths are not picked up

by

gap.

1

I

I

Fig.

8

Loading...

Loading...