The

Peak

Adjust

Circuit

The trim pot in this circuit oniy has

a

very small range,

%

dB.

It

is

for final high end adjustment. The frequency

to send in

is

18 kHz, record the tone

at

"O

VU" in, switch

to MONITOR and

read the result. Adjust trim pot

#l

1

R109, to read

"O

VU" in playback.

Both of the record equalization circuits

have rather

a

small range of adjustment. The high frequency adjust

is

3 dB, the peak adjust

is

%

dB. If you can't seem to get

a

"good" reading because you run out of adjustment range,

check these

3

points.

The "Record adjust" (point #9 in this review). Re-do,

send in

"O

VU"

at

1 kHz. Record the tone and read

playback. If

it

is

low, it will be impossible to get

15 kHz or 18 kHz up to

"O

VU." Reset and try again.

Still no good? Re-check the bias. If the bias current

is

too high, the high frequency sensitivity

is

reduced in

relation to the 1

kHz point. Check it out.

Switch the 80-8

to INPUT and send in

a

signal of 1 kHz

at

a

level of 1 volt

(O

dB,

+l

0 VU). Adjust the trim pot

#

12

R106.

22

k0hms until the LED goes on.

We suggest that you do this LED adjustment

as

rapidly

as

possible. +l0 VU

is

not good for the meter movement.

More than one minute of operation

at

+l0 may damage

the armature, so set everything up before applying the

signal and be brief.

With the 80-8

al1 buttoned up and the service door closed

you

can now check the Signal to Noise of the whole

system. You use the big test meter. Record with no input

signal and

read the result. The reading should be -60 dB

or better (un-weighted).

That's it. The whole procedure for an electronic overhaul

of the 80-8. Mechanical adjustments such

as

brake and

holdback torque,

ree1 height adjust and wow and flutter

measurements must be

done first, but they are major

service and should not be necessary "out of the box." The

transport logic

contro1 and switching system are described

in the

service manual.

We'll sell you

a

copy if you want one, but digital i.c.

theory

is

very complex and the necessary test equipment

for repairs costs more than the recorder. The

service

manual

is

not written

as

a

guide to the beginner, so be

advised,

it

may not help your understanding of the 80-8.

It is useful only to the experienced maintenance technician.

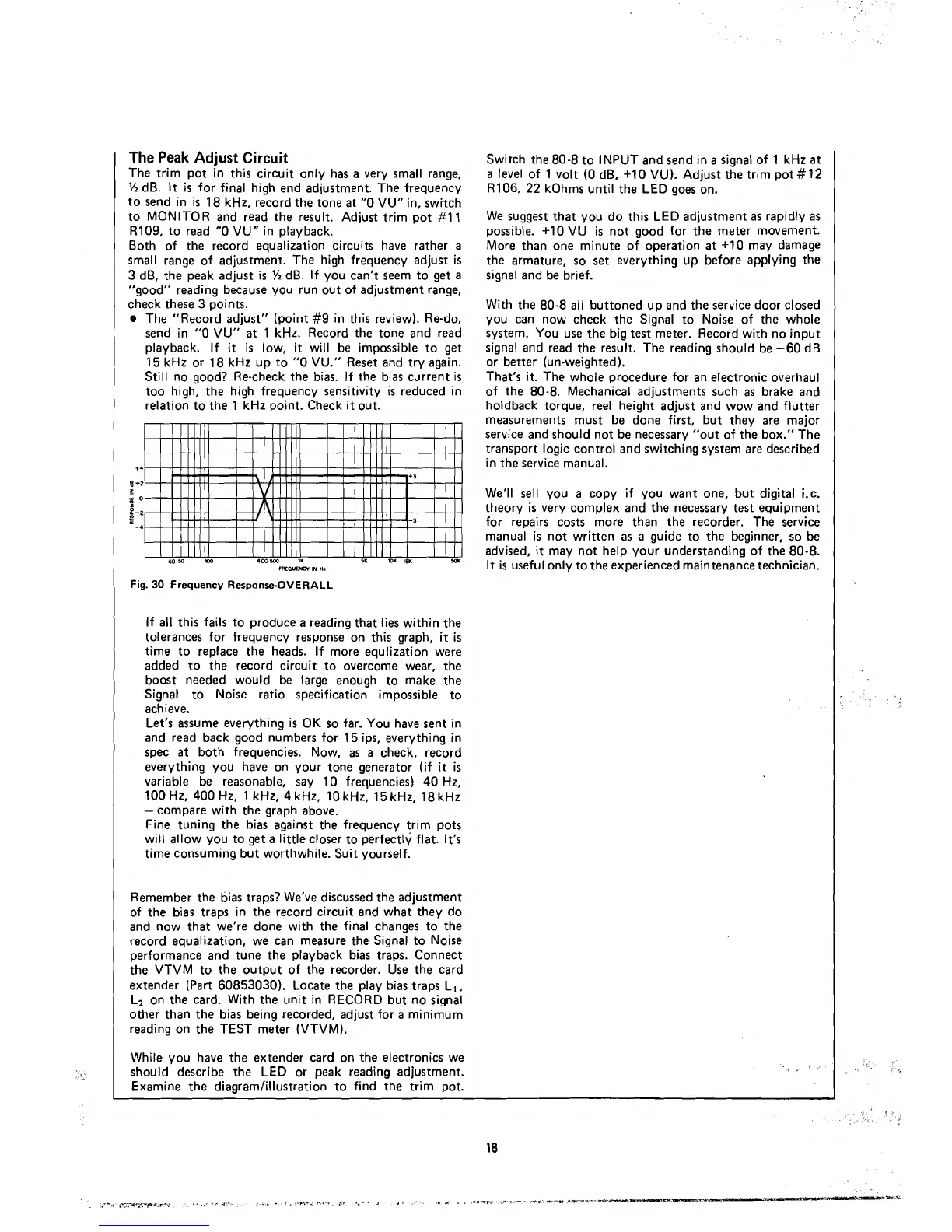

Fig.

30

Frequency Response-OVERALL

If

al1

this fails to produce

a

reading that lies within the

tolerances for frequency response on this graph,

it

is

time to replace the heads. If more equlization were

added to the record circuit to overcome wear, the

boost

needed would be large enough to make the

Signal to

Noise ratio specification impossible to

achieve.

Let's assume everything

is

OK so far. You have sent in

and

read back good numbers for 15 ips, everything in

spec

at

both frequencies. Now,

as

a

check, record

everything you

have on your tone generator (if

it

is

variable be reasonable, say 10 frequencies) 40 Hz,

100 Hz, 400 Hz, 1

kHz, 4 kHz, 10 kHz, 15 kHz, 18 kHz

-

compare with the graph above.

Fine tuning the bias against the frequency trim pots

will allow you to get

a

little closer to perfectly flat. It's

time consuming but worthwhile. Suit yourself.

Remember the

tjias traps? We've discussed the adjustment

of the bias traps in the record circuit and what they do

and now that we're

done with the final changes to the

record equalization, we

can measure the Signal to Noise

performance and tune the playback bias traps. Connect

the VTVM to the output of the recorder. Use the card

extender (Part 60853030). Locate the play bias traps L,,

Li on the card. With the unit in RECORD but no signal

other than the bias being recorded, adjust for

a

minimum

reading on the TEST meter (VTVM).

While you

have the extender card on the electronics we

should describe the LED or peak reading adjustment.

Examine the diagramlillustration to find the trim pot.

Loading...

Loading...