Page 7 - 18

Section 7 – Airframe and Systems description

FUEL SYSTEM

8. FUEL SYSTEM

The fuel system is designed to supply the reciprocating engine (Lycoming IO-

360-M1A) with the suitable flow rate and pressure according to engine limitations

required by Lycoming operator manual.

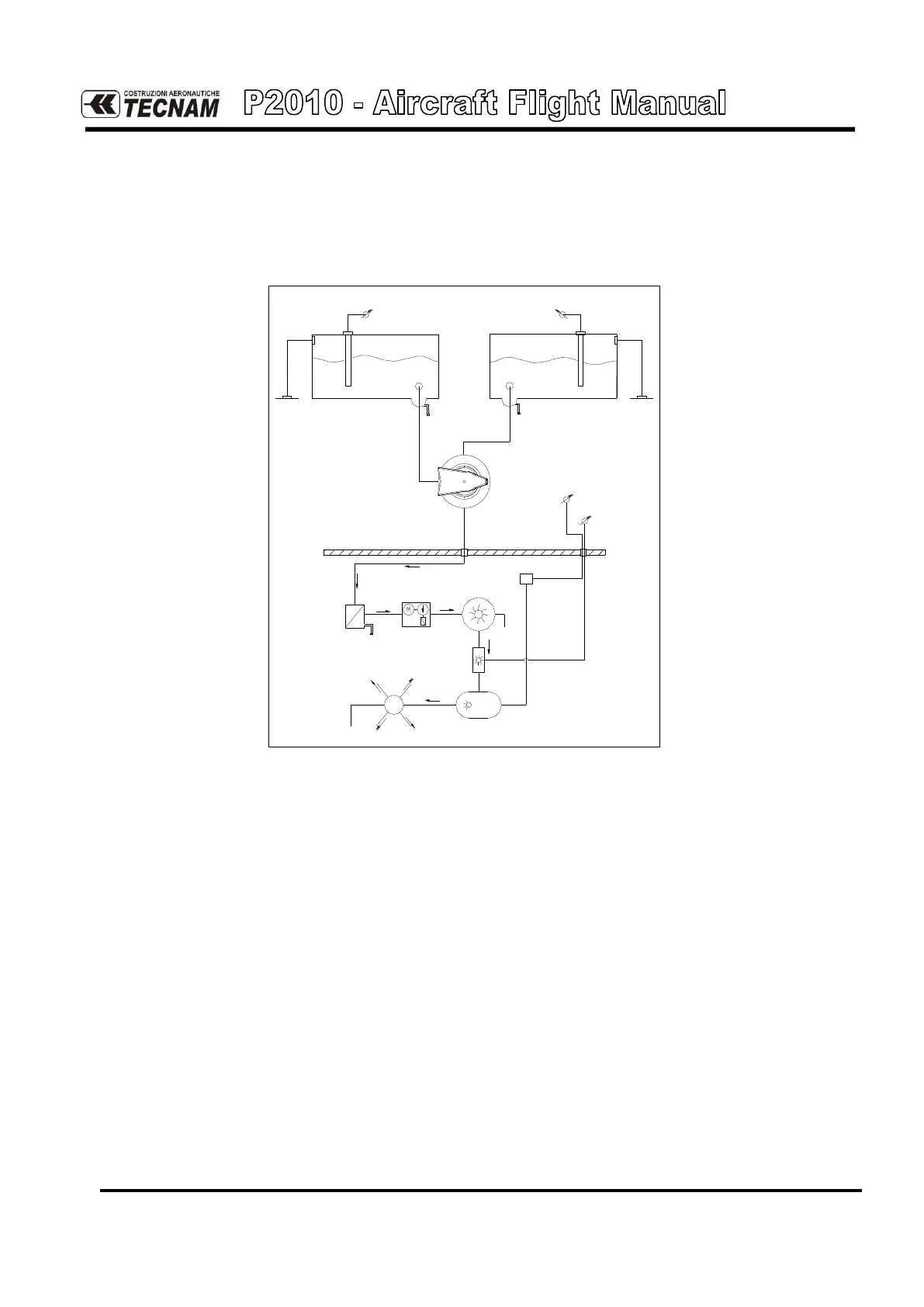

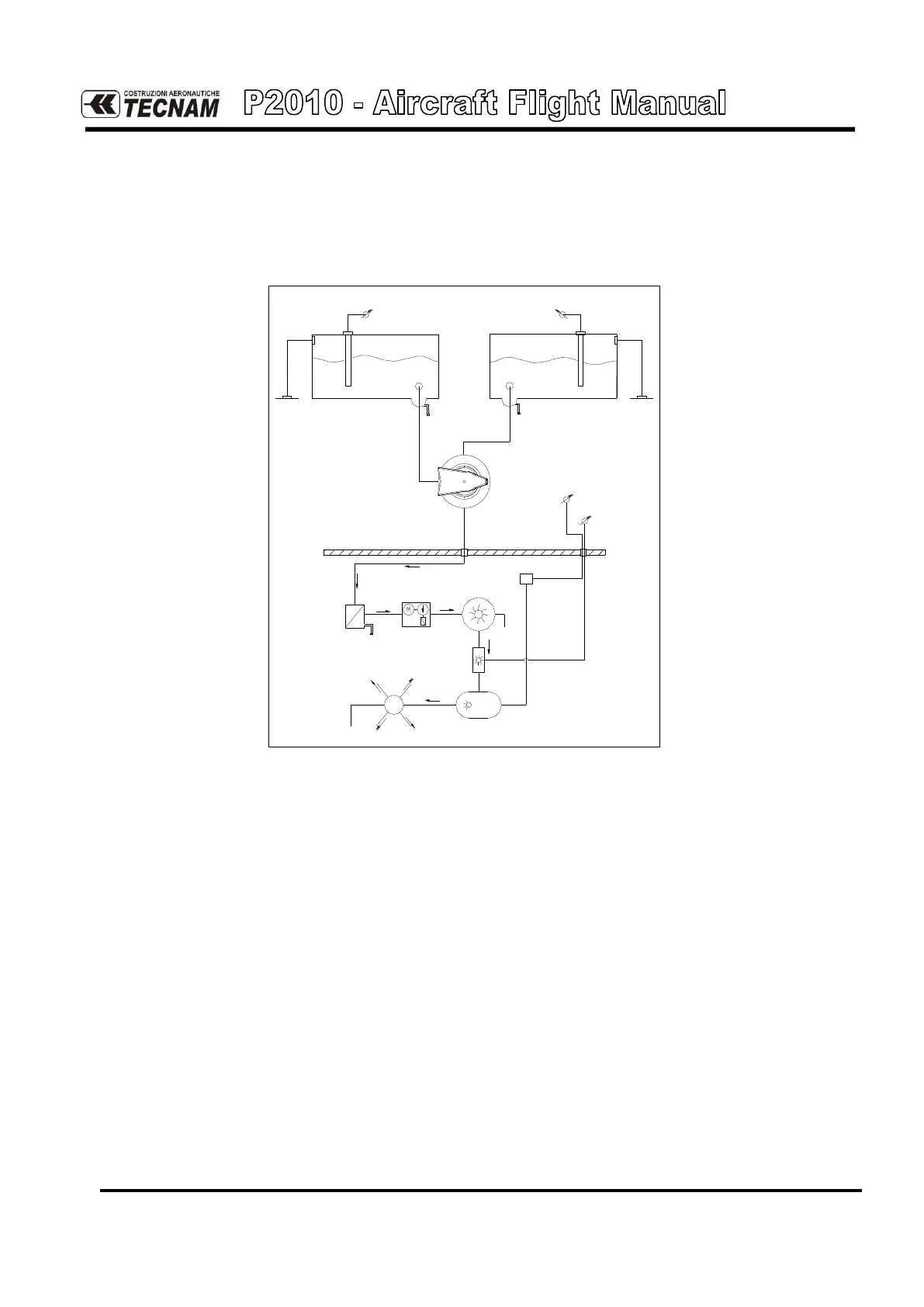

Following figure shows a schematic of the fuel system assy for P2010 airplane.

OFF

RH

LH

LH Fuel qty indicator

RH Fuel qty indicator

RH Fuel vent

LH Fuel vent

LH Fuel tank

RH Fuel tank

RH Fuel sump

LH Fuel sump

Firewall

Gascolator

Electric

fuel pump

Mechanical

fuel pump

Vent

Vent

Injector

Nozzle pressure

connection

Fuel pressure

sensor

Fuel flow

sensor

Fuel pressure

indicator

Fuel flow

indicator

Fig. 7-14. FUEL SYSTEM SCHEME

Each fuel tank is integrated within the wing box. The capacity of each tank is 120

liters (31,7 gal.), total capacity is thus 240 liters (63.4 gal.).

The internal side of fuel tank is accessible for inspection through 4 upper dedicat-

ed caps.

Two bottom inspection panels allow the inspection of vent line and tank structure.

An anti-sloshing movable wall is located within each fuel tank, this prevents fuel

centrifugation which is a possible cause of undesired engine shut down.

The fuel tank filler cap is located on the top of the wing, in the area outside of the

tank and it is easily accessible from the leading edge of the aircraft. At the lowest

point of the tank it is positioned a drain sump.

The engine is equipped with an engine gear pumps, mechanical (primary). An ad-

ditional auxiliary electrical fuel pump is provided (auxiliary).

The fuel selector is operated by a fuel selector control knob located in the cabin on

the central panel. The fuel selector control and the fuel valve are connected via a

rigid control rod.

Loading...

Loading...