5-11

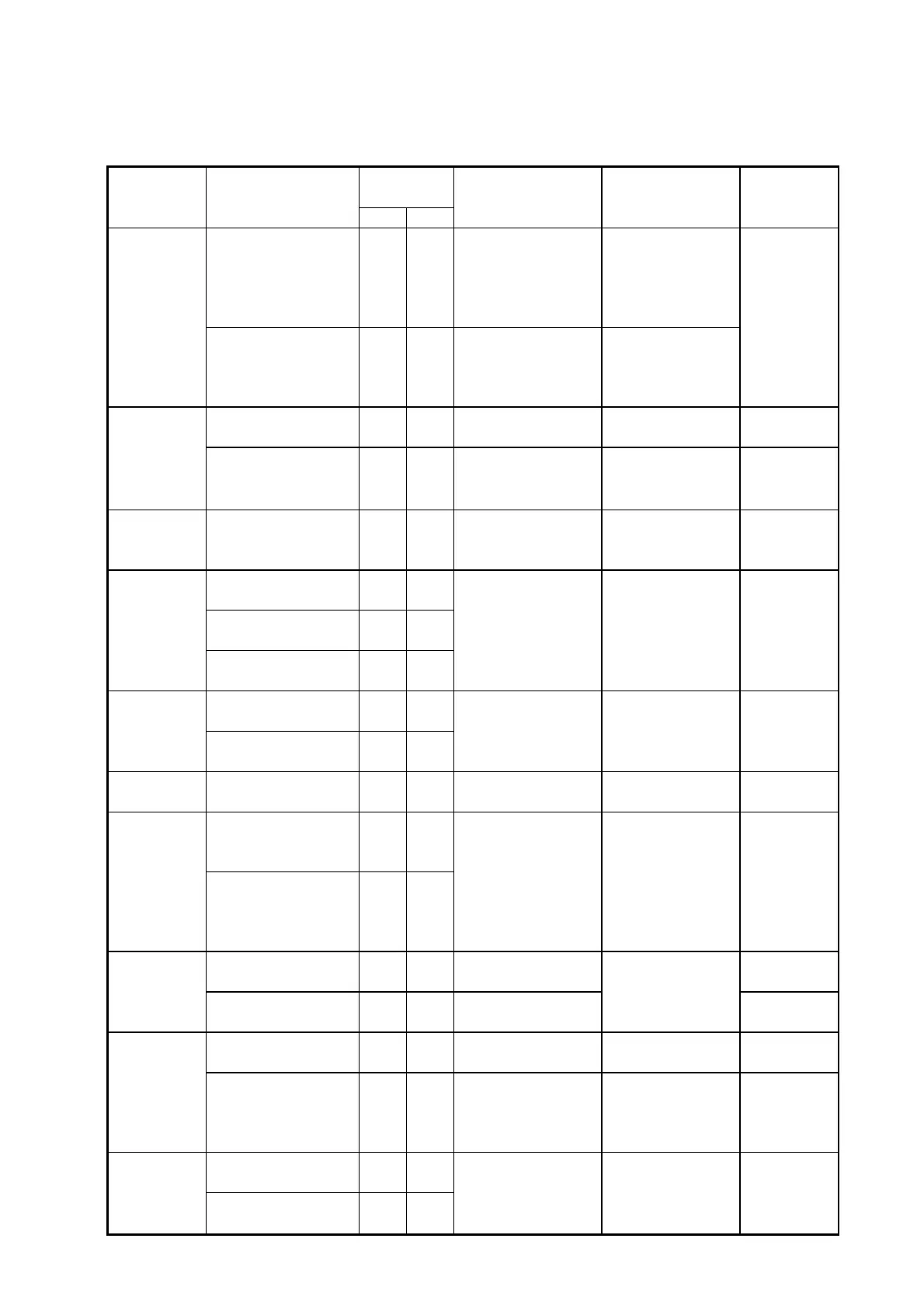

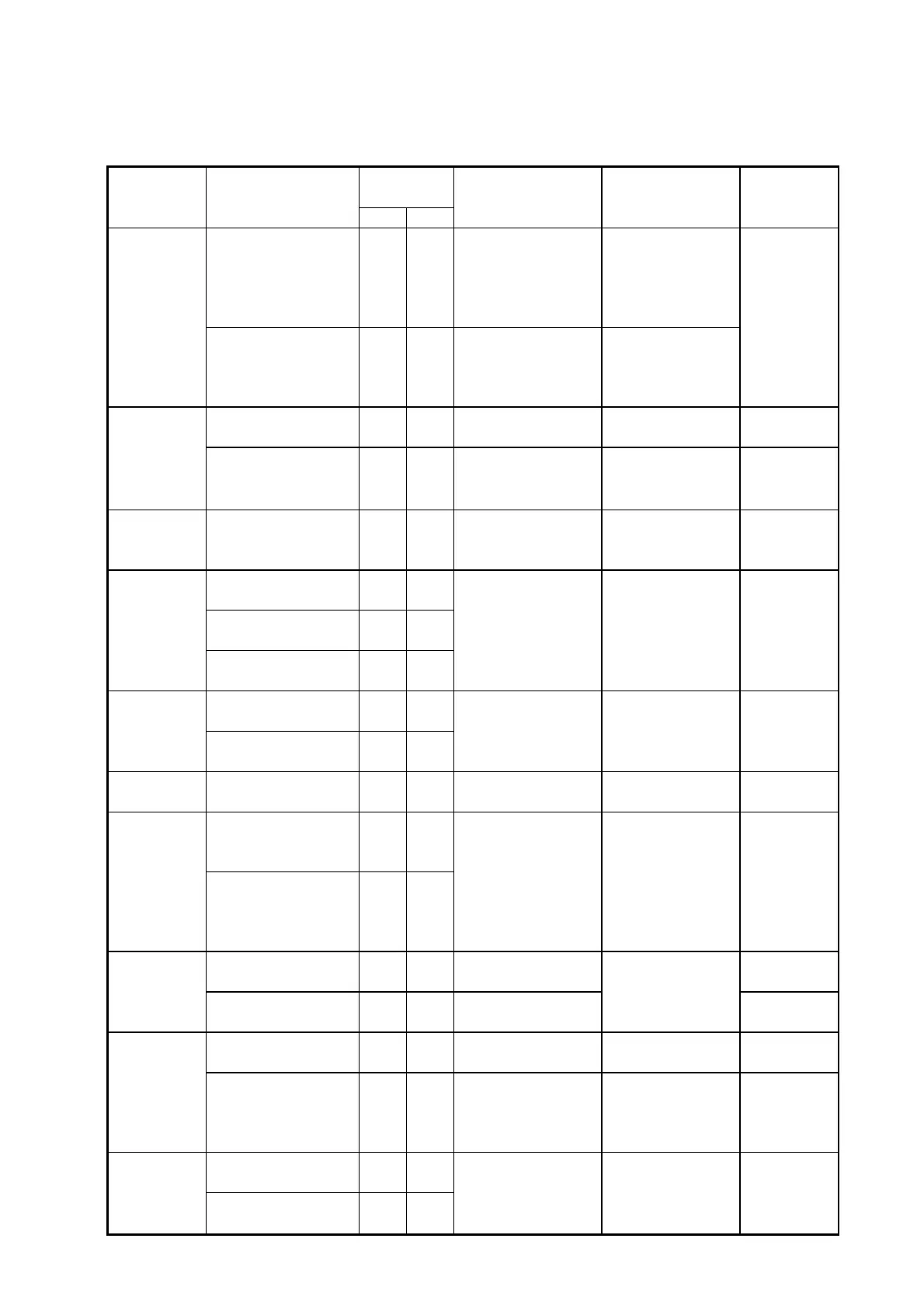

5.4 Routine and periodic inspection

To ensure stable and safe operations, check and maintain the inverter at regular intervals.

The table below lists the items to be checked to ensure stable and safe operations.

Check these items 5 minutes after the “Charge” indicator goes out to prevent injury to personnel

by residual electric power.

Items Details

period

Methods Criteria Remedies

Ambient

conditions

around the

machine

Confirm the

temperature and

humidity at the machine

○

thermometer and

hygrometer

according to

installation notices.

-10 – 40oC

(14-120℉)

Humidity: Below

95% RH

Improve the

ambient or

relocate the

drive to a

better area.

inflammable

materials in the

vicinity?

○

Visual check Keep area clear

Installation

and grounding

of the inverter

from the machine

○

Visual, hearing check

No vibration Secure screws

Is the grounding

resistance correct?

○

Measure the

resistance with a

multi-tester

below 100Ω

Improve the

grounding

Input power

voltage

Is the voltage of the

main circuit correct?

○

Measure the voltage

with a multi-tester

conform with the

specifications

Improve input

voltage

External

terminals and

internal

mounting

screws of the

inverter

loose?

○

Visual check

Check with a

screwdriver

Secure terminals

and no rust

Secure or

send back for

repair

damaged?

○

present?

○

Internal wiring

of the inverter

breaks?

○

Visual check No abnormalities

Replace or

send back for

repair

wire insulation?

○

Heat sink

debris

○

Visual check No abnormalities

debris or dust

Printed

circuit board

metal shavings or oil

sludge

○

Visual check No abnormalities

Clean or

replace the

circuit board

overheated,

or burned

parts

○

Cooling fan

noise

○

check

No abnormalities

cooling fan

or debris

○

Visual check Clean fan

Power

component

or debris

○

Visual check No abnormalities

component

resistance

between each

terminals

○

Measure with a

multi-tester

broken circuit in

three-phase

output

power

component

or inverter

Capacitor

leakage

○

Visual check No abnormalities

Replace

capacitor or

inverter

A

protrusion

○

Loading...

Loading...