Section 6—2205 Service

MAINTENANCE

This section contains information for conducting board removal procedures are included in the Cor-

preventive maintenance, troubleshooting, and cor- rective Maintenance part of this section,

rective maintenance on the instrument. Circuit

STATIC-SENSITIVE COMPONENTS

The following precautions are applicable when

performing any maintenance involving internal

access to the instrument.

a A A A A A A A A m

i CAUTION 1

Static discharge can damage any semi

conductor component in this instrument.

This instrument contains electrical components

that are susceptible to damage from static dis

charge. Table 6-1 lists the relative susceptibility of

various classes of semiconductors. Static voltages

of 1 KV to 30 KV are common in unprotected

environments.

When performing maintenance, observe the fol

lowing precautions to avoid component damage:

1. Minimize handling of static-sensitive

components.

2. Transport and store static-sensitive ; com

ponents or assemblies in their original containers or

on a metal rail. Label any package that contains

static-sensitive components or assemblies.

3. Discharge the static voltage from your body

by wearing a grounded antistatic wrist strap while

handling these components. Servicing static-

sensitive components or assemblies should be

performed only at a static-free work station by

qualified service personnel.

4. Nothing capable of generating or holding a

static charge should be allowed on the work station

surface.

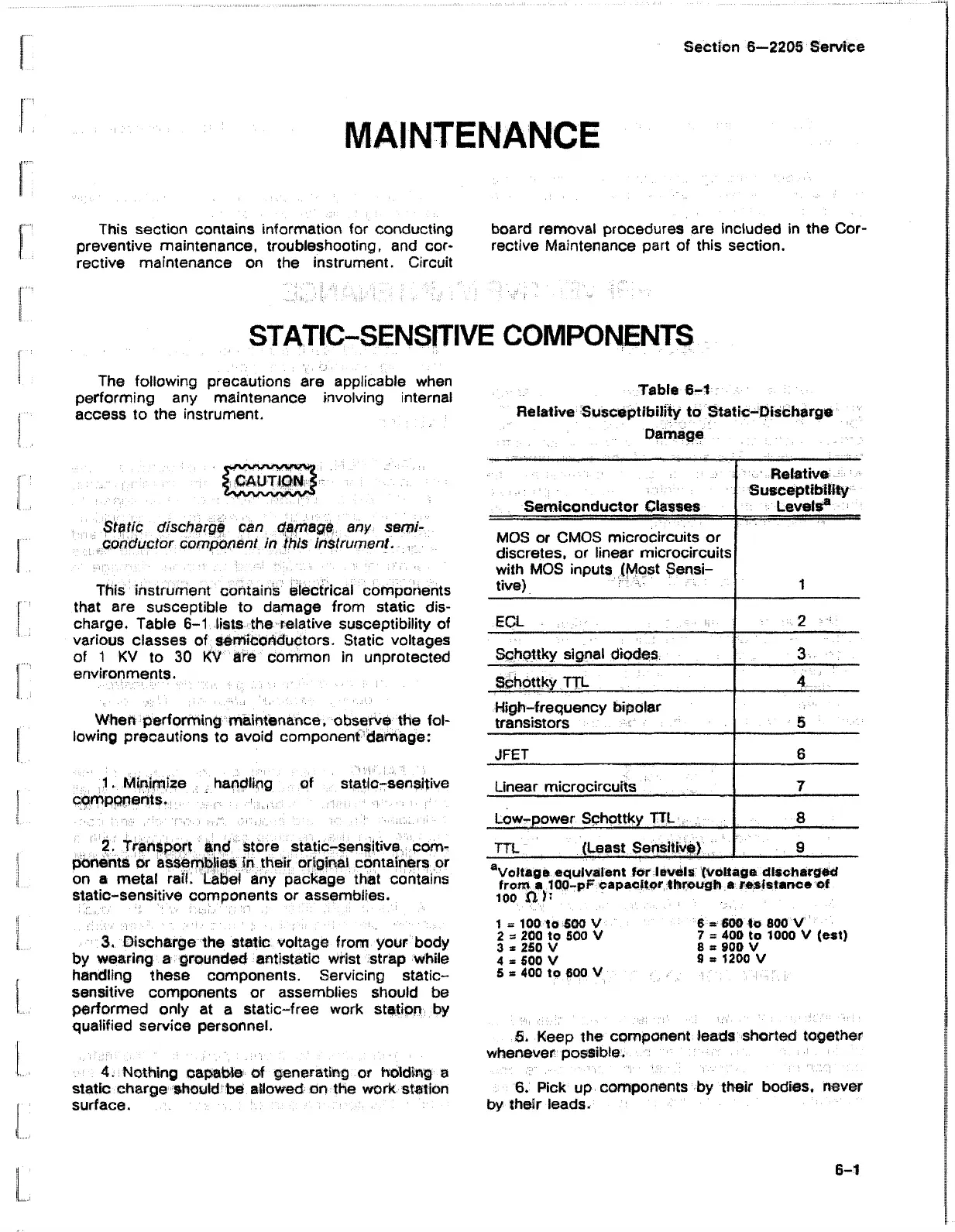

Table 6-1

Relative Susceptibility to Static-Discharge

D am ag e

..........

Semiconductor Classes

Relative-

Susceptibility

Levels®

MOS or CMOS microcircuits or

discretes, or linear microcircuits

with MOS inputs (Most Sensi

tive)

1

ECL .

2

Schottky signal diodes 3

Schottky TTL

4

High-frequency bipolar

transistors

5

JFET 6

Linear microcircuits

7

Low-power Schottky TTL

8

TTL (Least Sensitive)

■ : 9

aVoltage equivalent ter levels (voltage discharged

from a 100-pF capacitor through a resistance of

100 P'J1

1 = 100 to 500 V 6 = 600 to 800 V

2 a 200 to 500 V 7 = 400 to 1000 V (est)

3 * 250 V 8 s 900 V

4 3 500 V 9 * 1200 V

5 3 400 to 600 V

5. Keep the component leads shorted together

whenever possible.

6. Pick up components by their bodies, never

by their leads.

6-1

Loading...

Loading...