Adjustment Procedure—2205 Service

i. Set the Vertical MODE switch to CH 1.

j. Repeat parts b through g using the Channel 1

controls.

f. Check Position Range

a. Set:

VOITS/DIV (both) 10 mV

AC-GND-DC (both) AC

SEC/DIV 0.2 ms

Trigger COUPLING AC

b. Set the calibration generator for 0.1 V.

c. Adjust the CH 1 VOLTS/DIV variable control to

produce a 5.25-division display.

d. Set the CH 1 VOLTS/DIV to 5 mV.

e. Set the calibration generator to produce a

0.2 V signal.

f. CHECK—The bottom and top of the trace may

be positioned above and below the center horizontal

graticule line by rotating the CH 1 POSITION control

fully clockwise and counterclockwise respectively.

g. Move the cable from the CH 1 or X input con

nector to the CH 2 OR Y input connector.

h. Set the Vertical MODE switch to CH 2.

i. Repeat parts b through f using the Channel 2

controls.

j. Disconnect the test equipment from the

instrument.

6. Adjust Attenuator Compensation

a. Set:

VOLTS/DIV (both) 10 mV

AC-GND-DC (both) DC

b. Connect the high-amplitude, square-wave

output from the calibration generator via a 5 0 -fl ter

mination r a miniature probe tip to BNC adapter, and

the 10X probe to the CH 2 OR Y input connector.

c. Set the generator to produce a 1-kHz, 5-

division display and compensate the probe using the

probp compensation adjustment (see the probe

instruction manual).

d. Replace the probe and miniature probe tip to

BNC adapter with a 50-fl coaxial cable and 50-0

termination.

e. Set the generator to produce a 5-division

display.

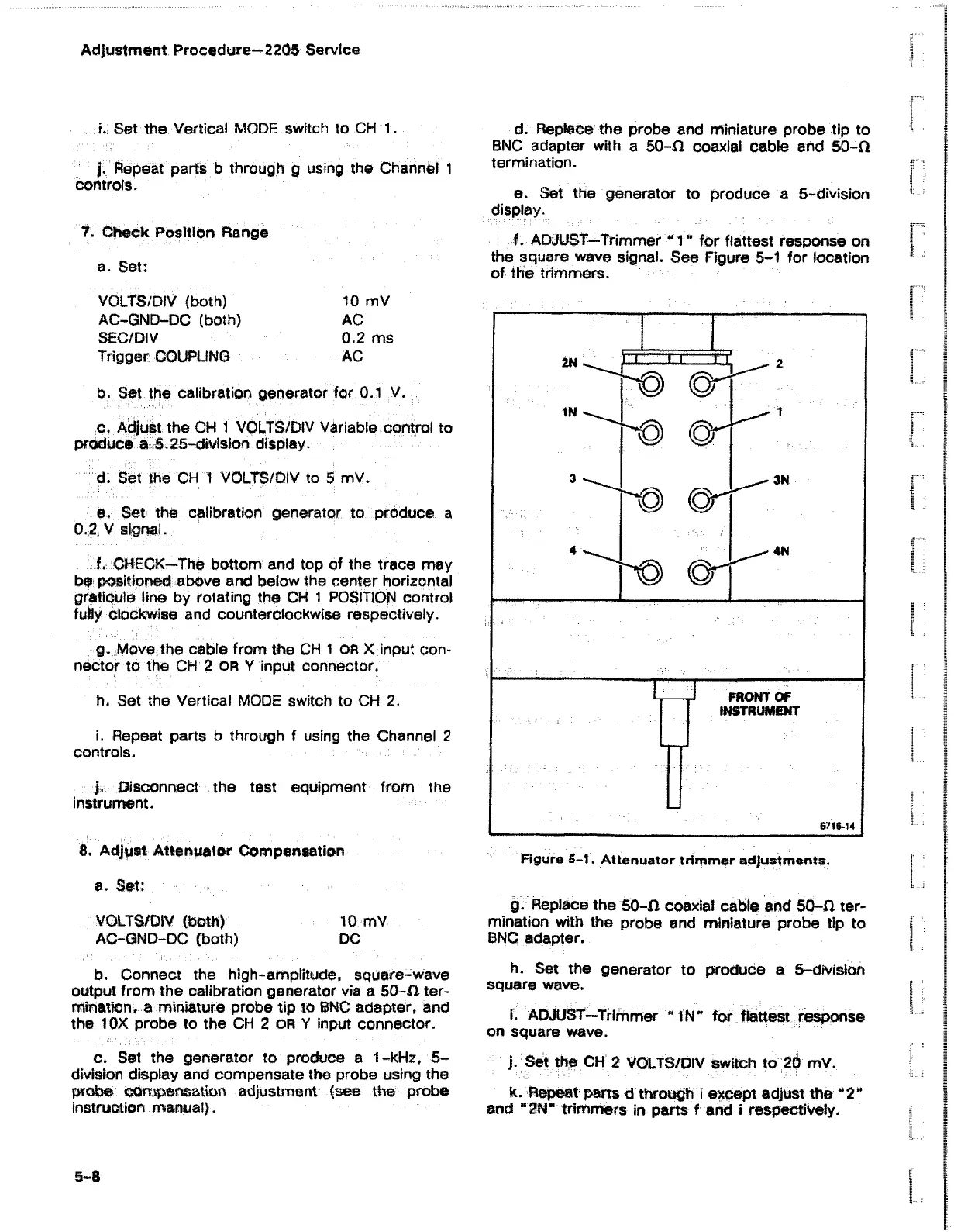

f. ADJUST—Trimmer " 1 ” for flattest response on

the square wave signal. See Figure 5-1 for location

of the trimmers.

g. Replace the 50-fl coaxial cable and 50-fl ter

mination with the probe and miniature probe tip to

BNC adapter.

h. Set the generator to produce a 5-division

square wave.

i. ADJUST—Trimmer "IN ’’ for flattest response

on square wave.

j. Set the CH 2 VOLTS/DIV switch to 20 mV.

k. Repeat parts d through i except adjust the “ 2*

and “ 2N” trimmers in parts f and i respectively.

5-8

Loading...

Loading...