TM 11-6625-2735-14-1

1. Semiconductor Tester

Description: Dynamic

— type tester. Must be capable of

measuring reverse breakdown voltages of at least

400 volts.

Purpose: To test the semiconductors used in this

instrument.

Recommended type: Tektronix 576 Curve Tracer or

Tektronix 577 (D1 or D2) Curve Tracer with 177 Test

Fixture.

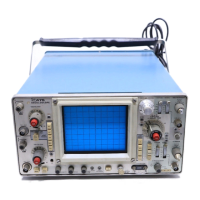

2. Test Oscilloscope

Description: Frequency response, dc to 75 megahertz

or greater; deflection factor, 1 millivolt to 5 volts/division;

Input impedance, 1 megohm, 20 picofarads; sweep rate,

0.5 second/division to 50 nanoseconds/division. A 10X,

10-megohm voltage probe should be used to reduce

circuit loading for waveform measurements. A 1X, 1-

megohm voltage probe should be used for power supply

ripple checks.

Purpose: To check operating waveforms in this instru-

ment.

Recommended type: Tektronix 7603 Oscilloscope with

7A13 Amplifier and 7650 Time-Base units. Use a P6053

10X probe and a P6011 1X probe.

3. Multimeter

Description:

Non-loading

Digital Multi meter.

Voltmeter, 10 megohm input impedance and 0 to 150 volts

range; dc voltage accuracy, within 0.15%; display, 4-1/2

digits. Ohmmeter,

0 to 20 megohms.

Purpose: To check voltages and for general

troubleshooting in this instrument.

Recommended type: Tektronix DM 501 Digital Multi-

meter (requires a TM 500-series power module).

4. Variable Autotransformer

Description: Output variable from

0 to 140 volts, 1.2

amperes minimum rating. Must have 3-wire power cord,

plug, and receptacle.

Purpose: To vary the input line voltage when

troubleshooting in the power supply.

Recommended type: General Radio W8MT3VM or

W10MT3W Metered Variac Autotransformer.

Troubleshooting Techniques

This troubleshooting procedure is arranged in an order

which checks the simple trouble possibilities before

proceeding with extensive troubleshooting. The first few

checks ensure proper connection, operation and calibra-

tion. If the trouble is not located by these checks, the

remaining steps aid in locating the defective component.

When the defective component is located, it should be

replaced following the replacement procedure given

under Corrective Maintenance.

1. Check Control Settings. Incorrect control settings

can indicate a trouble that does not exist. If there is any

question about the correct function or operation of any

control, see the Operating Instructions section of this

manual.

2. Check Associated Equipment. Before proceeding

with troubleshooting of the 475, check that the equipment

used with this instrument is operating correctly. Check

that the signal is properly connected and that the inter-

connecting cables are not defective. Also, check the

power source.

3. Check Instrument Calibration. Check the calibra-

tion of this instrument, or the affected circuit if the trouble

exists in only one circuit. The apparent trouble may only

be a result of misadjustment and may be corrected by

calibration. Complete calibration instructions are given in

the Calibration section of this manual.

4. Visual Check. Visually check the portion of the

instrument in which the trouble is located. Many troubles

can be located by visual indications such as unsoldered

connections, broken wires, damaged circuit boards,

damaged components, etc.

5. Isolate Trouble to a Circuit. To isolate trouble to a

particular circuit, note the trouble symptom. The symptom

often identifies the circuit in which the trouble is located.

When trouble symptoms appear in more than one circuit,

check affected circuits by taking voltage and waveform

readings. Typical voltages and waveforms are given on the

schematics in the Diagrams section.

6. Circuit Troubleshooting Sequence. If the instru-

ment is found to have inoperative functions in more than

one area of the main oscilloscope circuits, repair the

circuits in the order specified in the following list.

a. L.V POWER SUPPLY (Check +50 V, +110 V,

+15 V, +5V,

—15 V and –8 V supplies.)

4-10

Loading...

Loading...