TROUBLESHOOTING 4-4 Manual 0-2957

4.06 Circuit Fault Isolation

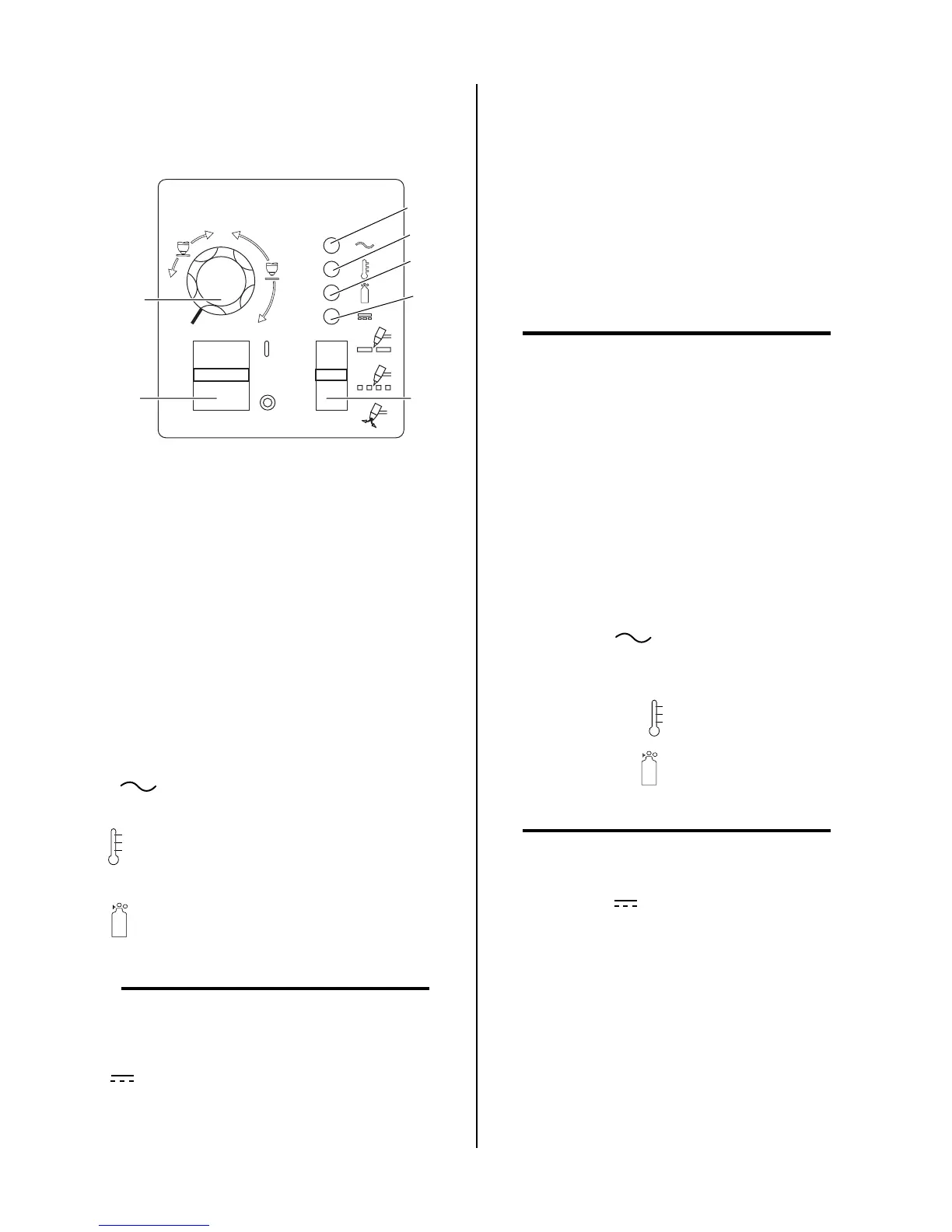

A. Controls and Indicators

Art # A-03845

A

20

40

60

3

5

4

1

2

6

7

1. ON/OFF switch. This switch controls AC power to the

unit. Up is ON, down is OFF.

2. RUN / RAPID AUTO RESTART / SET switch. This

switch controls gas flow to the torch. Up is RUN, for

general torch operation. Center position is RAPID

AUTO RESTART, for an uninterrupted restart when

cutting expanded metal or in gouging or trimming op-

erations. Down is SET, for setting gas pressure and

purging lines.

3. Current control knob (A) This control regulates cur-

rent to the torch. At output settings over 40 amps, cir-

cuitry in the power supply automatically reduces out-

put current to 40 amps if the torch tip contacts the

workpiece.

4. AC indicator When lit, indicates operating

power is present in the unit.

5. TEMP indicator turns on when internal sensors

detect temperatures above normal limits.

6. GAS indicator Indicates adequate gas pressure

for power supply operation.

NOTE

Minimum gas pressure for power supply opera-

tion is lower than the minimum for torch opera-

tion.

7. DC indicator Indicates DC power output circuit

is active. (Torch must be activated).

B. Initial Setup Conditions

This section is to help isolate the defective circuit before

troubleshooting, identify symptoms, and test the unit for

proper operation. Follow the instructions as given to iden-

tify the possible symptom(s) and the defective circuit.

After repairs are complete, run the following tests again

to verify that the unit is fully operational.

1. Connect gas supply to rear of Power Supply.

2. Turn on gas supply and set operating pressure per

pressure setting label on power supply.

NOTE

Minimum gas pressure for power supply operation

is lower than the minimum for torch operation.

3. Set the Power Supply controls as follows:

• ON/OFF switch to OFF (Down)

• RUN / RAPID AUTO RESTART / SET switch to

SET (Down)

• CURRENT control (A) to maximum

C. Main Input and Internal Power Tests

1. Connect main AC power to the unit.

2. Set the Power Supply ON/OFF switch to ON (up) and

note the following:

• AC indicator is steady ON

• Main PCB Relay energizes, pulling in main input

contactor (W1)

• TEMP Indicator is OFF

• GAS Indicator is ON if input pressure is suffi-

cient for power supply operation.

NOTE

Minimum gas pressure for power supply operation

is lower than the minimum for torch operation.

• DC indicator is OFF

• Gas flows

• Fans operate

3. Set the Power Supply RUN / RAPID AUTO RESTART

/ SET switch to the RUN (up) position and note the

following:

• Gas flow stops

This completes the Main Input and Internal Power Tests.

If the above are all correct then proceed to paragraph 'D'. If

not, note the symptom and proceed to Subsection 4.07,

Main Input and Internal Power Problems.

Loading...

Loading...