Manual 0-2582 21 SERVICE TROUBLESHOOTING

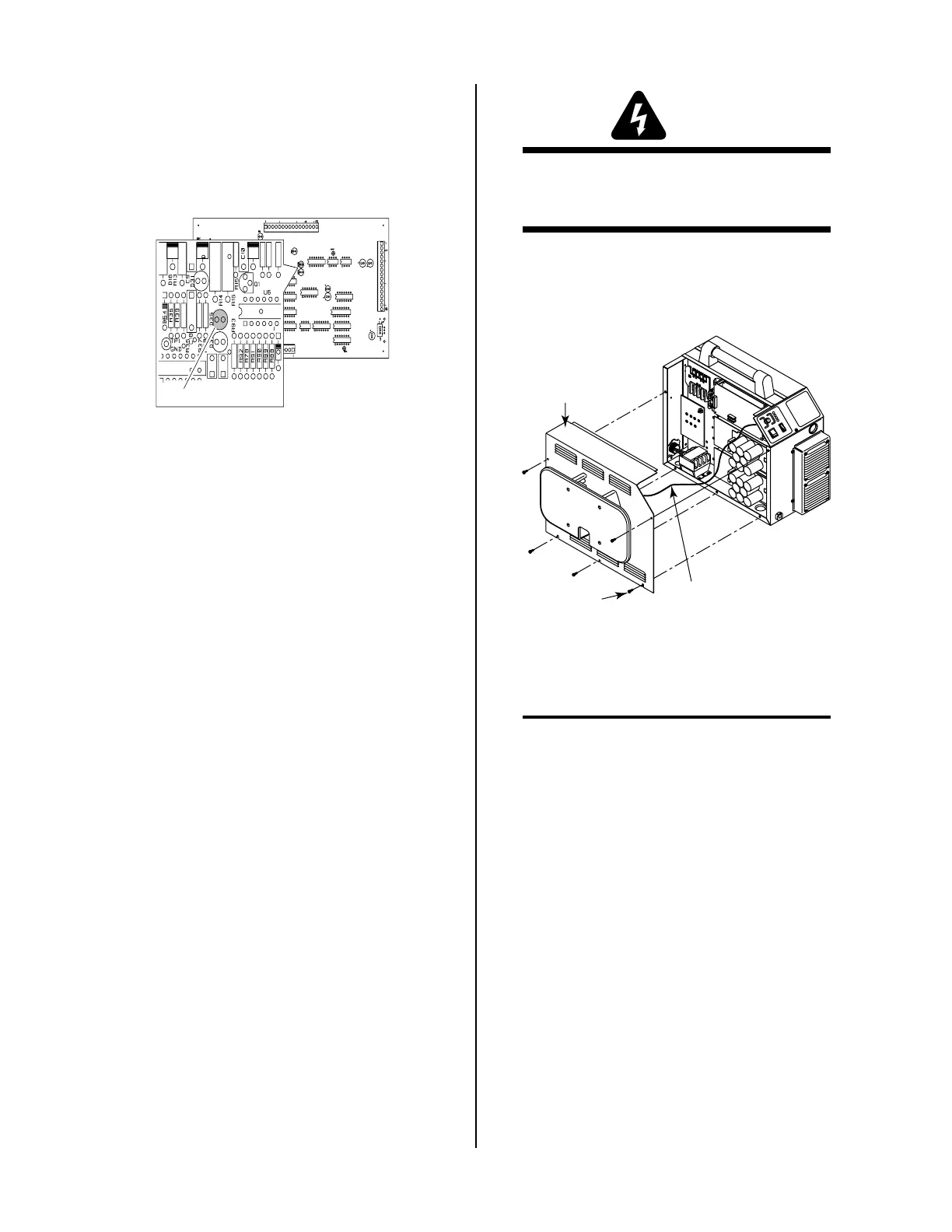

2. Faulty Logic PC Board

If torch tip is off the workpiece and the drag indi-

cator, D35, on the Logic PC Board is still ON, then

replace the Logic PC Board

A-01407

Logic PC Board

D35

4.09 Test Procedures

The test procedures in this subsection are referenced in

the troubleshooting section.

A. Safety Precautions

1. Significant DC Voltage exists after removal of input

power. Allow 2 minutes for discharge time. Voltage

measured on input capacitors must be zero before

performing service on the power supply.

2. Do Not touch electrical components with any part of

the human body when power is applied.

3. Keep away from any moving parts.

4. Hot surfaces can cause severe burns. Allow equip-

ment to cool before servicing.

5. Electrostatic discharge can damage printed circuit

board assemblies. Transport printed circuit boards in

proper anti-static shielded packages. Use proper

grounding techniques with wrist strap before handling

printed circuit boards.

6. Misaligned plugs can cause printed circuit board dam-

age. Be sure plugs are properly aligned and com-

pletely seated.

7. Excessive pressure can damage printed circuit board.

Use only minimal pressure and gentle movement

when disconnecting or connecting printed circuit

board plugs.

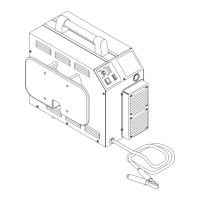

B. Opening Power Supply Enclosure

The left side panel of the Power Supply must be removed

to gain access to the input power connections and the

input voltage selection.

WARNING

Disconnect primary power at the source before as-

sembling or disassembling the Power Supply, torch

parts, or torch and leads assemblies.

1. Using a phillips head screw driver remove the five

screws which secure the left side panel (viewed from

front of unit) to the frame assembly.

Screws

(5 Places)

Left Side

Panel

A-01346

Ground Wire

2. Carefully pull the left side panel from the Power Sup-

ply a short distance (see note).

NOTE

There is a ground wire attached to the side panel.

3. Remove the nut securing the ground wire to the side

panel.

4. Close the enclosure by reversing the above steps.

C. Diode Testing Basics

Testing of diode modules requires a digital volt/ohmme-

ter that has a diode test scale. Remember that even if the

diode module checks good, it may still be bad. If in doubt,

replace the diode module.

1. Locate the diode module to be tested.

2. Remove cables from mounting studs on diodes to iso-

late the module.

3. Set digital volt/ohmmeter to diode test scale.

4. Using the Figures for each test, check each diode in the

module. Each diode must be checked in forward bias

(plus to negative) and reverse bias (negative to plus)

direction.

Loading...

Loading...