MP-3000 Controller

65

1

Setpoint temperature and Economy mode setting

determine the evaporator fan speed:

• Normal Operation (Economy mode off): Chill

Loads — High speed fans; Frozen Loads —

Low speed fans.

• Economy mode set to On: Chill Loads —

Fans switch from high speed to low speed

when temperature is in-range. Frozen Loads

— Low speed fans during cooling; fans are off

during Null mode but operate on low speed

for 5 minutes every 45 minutes.

2

Liquid injection valve:

• Chill or Power Limit Mode: When the

modulation capacity is 91% or less.

• Compressor High Temperature Protection:

When the compressor discharge temperature

exceeds 128 to 138 C (262 to 280 F).

3

Chill Loads only: Controller Opens (energizes)

the warm gas bypass valve continuously when the

modulation capacity is approximately 50% or

less.

4

Condenser fan pulses on and off on a 30 second

duty cycle to maintain a minimum condenser

temperature:

• Chill Loads: Controller maintains a minimum

30 C (86 F) condenser temperature.

• Frozen Loads: Controller maintains a

minimum 20 C (68 F) condenser temperature.

NOTE: Condenser fan does not operate

when the water pressure switch (option) is

open.

5

Stepper motor valve modulates: Chill Loads —

whenever the unit is in a Cooling mode; Power

Limit — whenever the unit is in Power Limit

mode.

6

Coil/Dehumidify Valve: Controller energizes

(closes) the coil/dehumidify solenoid valve when

the modulation capacity is 20% or less. This

closes refrigerant distribution to 50% of the

evaporator coil to reduce cooling capacity. The

valve remains closed until the modulation

capacity increases to 25%.

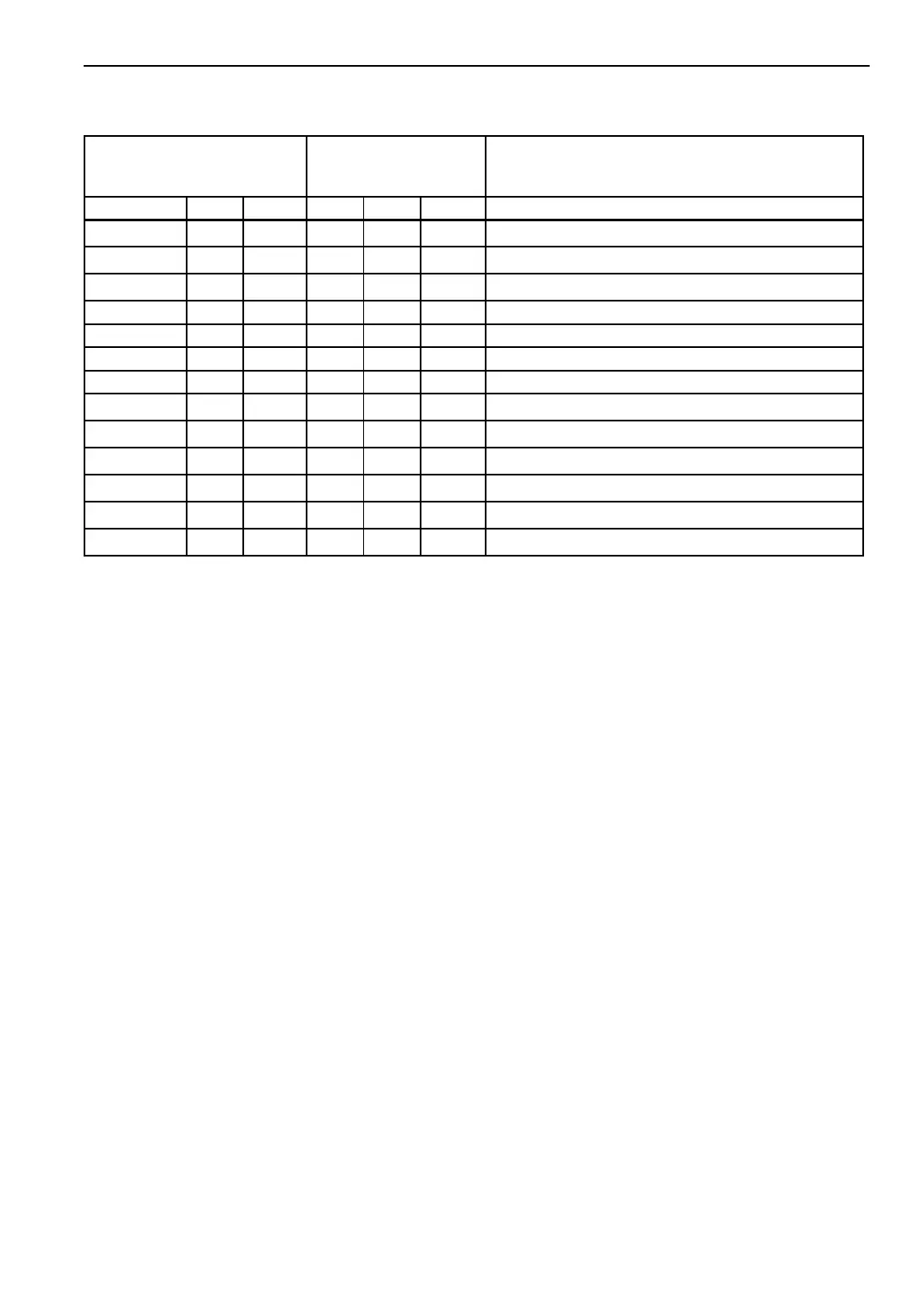

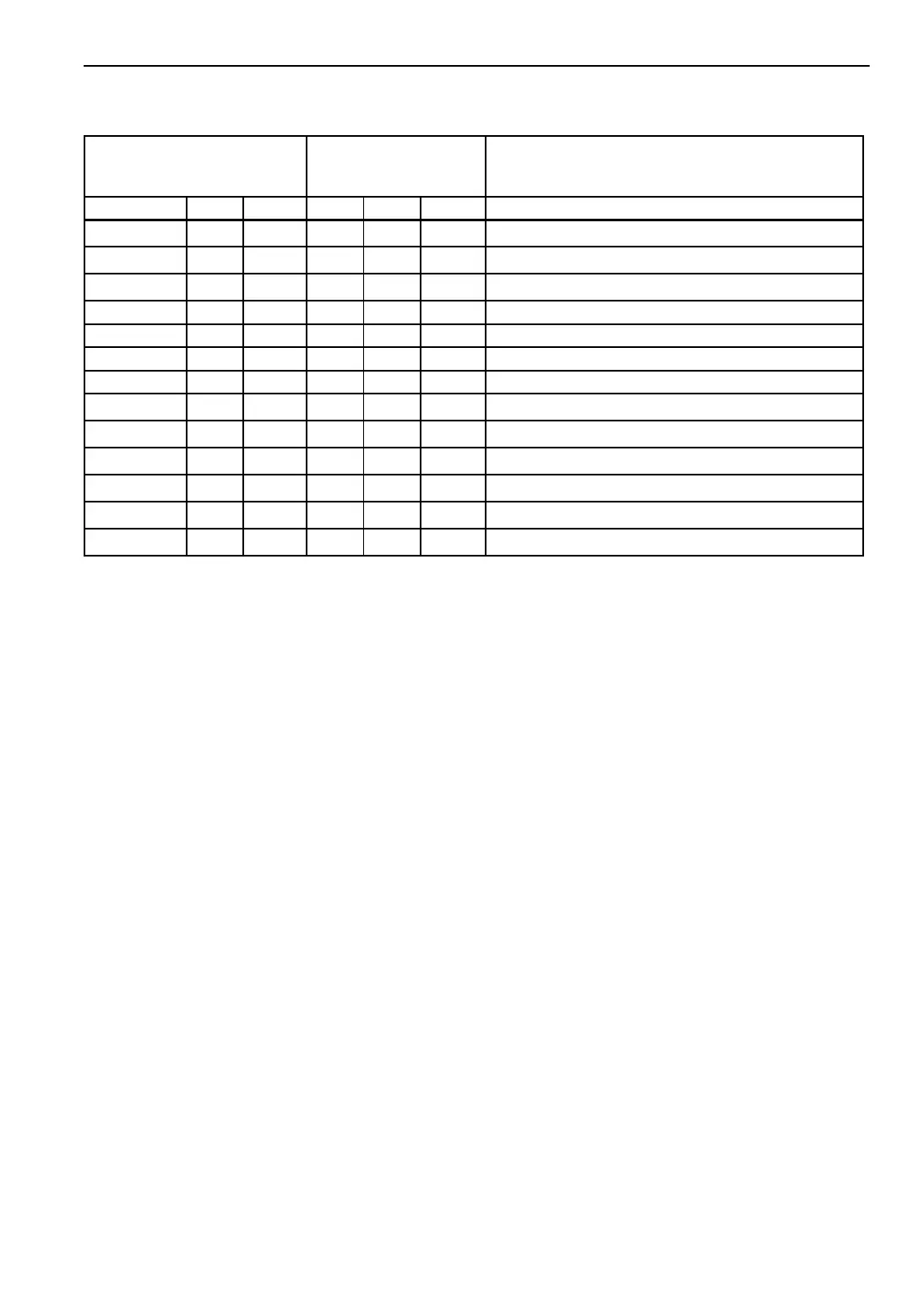

CSR Operating Mode Function Chart

Chill Loads

Setpoints at -9.9 C

(14.4 F) and Above

Frozen Loads

Setpoints at -10 C

(14 F) and Below

Cool w/Mod Heat Defrost Cool Null Defrost Unit Function

•

1

•

Evaporator Fans High Speed

1

•

1

•

•

1

Evaporator Fans Low Speed

1

•

•

1

•

Evaporator Fans Off

1

•• Proportional-integral Derivative (Supply Air) Control

•• Return Air Sensor Control

••Evaporator Coil Sensor Control

••Compressor On

••

Compressor Liquid Injection On (valve energized)

2

•

Warm Gas Bypass Solenoid Valve Open (energized)

3

••

Condenser Fan On

4

•

•

5

Stepper Motor Valve Modulating (energized)

5

•

Coil/Dehumidify Solenoid Valve Closed (energized)

6, 7

•

8

•• •

Electric Heaters Pulsing or On (energized)

8

Loading...

Loading...