WARNER ELECTRIC EUROPE - Rue Champfleur, B.P. 20095, F - 49182 St Barthélemy d’Anjou Cedex SM421gb - rev 12/09 3/5

Symbol designating

an action that might

damage the brake

Symbol designating an

action that might be dan-

gerous to human safety

Symbol designating an elec-

trical action that might be

dangerous to human safety

2 Precautions and restrictions on use

2.1 Restrictions on use

●

For the brake to comply with directive 95 / 16

/ EC, the integrator must observe the general

conditions for installation, including the man-

datory use of a speed limiting device, in

compliance with EN 81-1 paragraphs 9.9 and

9.10.10., as stated in the EC type-examination

certificate from TÜV SÜD Industrie Service (see

ABV number in Table 1).

This brake can in no way replace the system

against the overspeed of the cabin downwards

●

This brake is designed to work in dry condi-

tions. Any contact with oil, grease, water or

abrasive dust causes a decrease in torque.

Warning : It is the responsibility of the

customer to install the covers needed to avoid

pollution of friction faces.

●

Torque subject to decrease in case of water

contamination. Use of both brake circuits

mandatory.

Warning : brake must be replaced after water

contamination.

●

This product is not suitable for use according to

ATEX/94/9/EC.

●

These units are designed for use in an ambiant

temperature between 0° C and +40° C

maximum.

Warning : at low temperature, any freezing of

the friction face, due to condensation, generates

a loss of torque. It is the responsability of the

customer to take measures to avoid this

problem.

●

If maximum rotation speeds are exceeded, the

guarantee is no longer valid.

●

It is mandatory to follow instructions and datas

given in documentation and marking of the units,

in order to ensure the performance of

the brake.

●

This brake may only be used in a "horizontal

axis".

●

The customer must be careful not to alter the

factory-set airgap. This is in order to ensure the

brakes will be properly released.

●

Protection class

Mechanical : IP10

Electrical : IP42

●

Insulation class F 155 °C

●

Normal use will not lead to any noticeable wear

on the lining. Any dynamic braking is

restricted to emergency and test braking.

2.2 Precautions and safety measures

●

During maintenance, make sure that the

mechanism to be held by the brake, is switched

off and that there is no risk of it accidentally

starting up. All interventions have to be made by

qualified personnel, using this manual.

●

Any modification made to the brake without the

express authorisation of a representative of

Warner Electric, in the same way than any use

out of the contractual specifications accepted

by "Warner Electric", will result in the warranty

being invalidated and Warner Electric will no

longer be liable in any way with regard to

conformity.

3 Installation

3.1 Transport / storage

This brake is delivered in standard packaging

that will keep it intact for a period of 6 months

during ground transport.

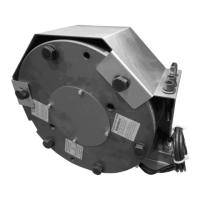

3.2 Handling

●

Avoid any impact to the brake so that its

performance is not impaired

●

Never lift the brake by its cables

When handling, use the handling holes intented

for this purpose (see Fig. 2 Thread M10)

3.3 Installation

Specifications for the customer’s friction face:

Material: Steel (150 to 250 HV) or Cast iron

Roughness ≤ Ra 3,2

Protection: Phosphatizing (dry) or nitriding

Geometrical tolerances:

The brake is delivered pre-assembled with pre-set

microswitches and airgaps. Fixing screws and the hub are

supplied separately,

• Retighten the 2 transport screws CHc M8

• Mount the hub on the customer’s shaft

NOTA : hold the hub in axial direction (retainer)

Loading...

Loading...