42

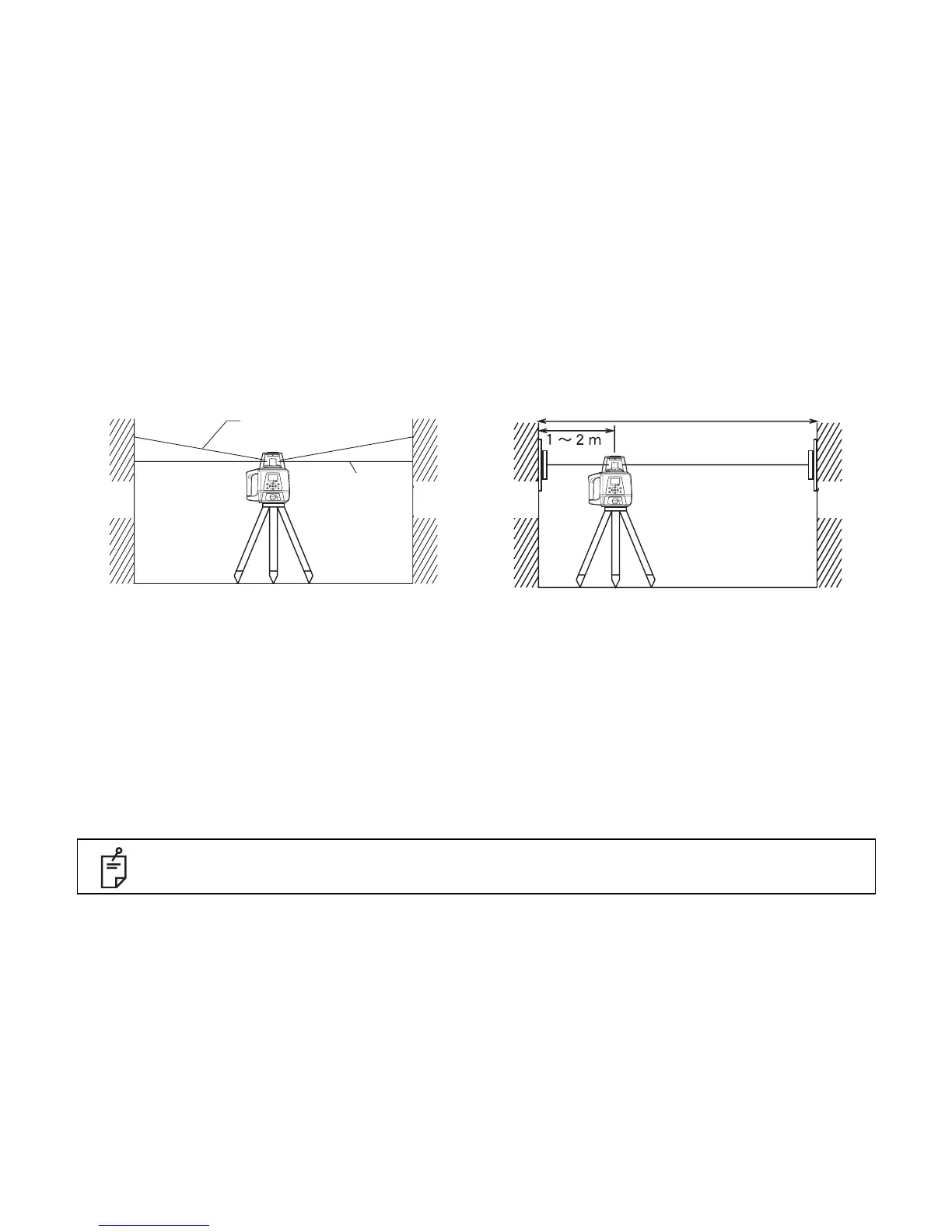

Horizontal Rotation Cone Error

Perform the following check after completing “Horizontal Calibration” on the previous

page.

1 Set up the laser centered between two walls approximately 50 m (164 ft) apart. Orient the

instrument so one axis, either X or Y, is facing the walls. Grade should be set to 0.00% in both

axes.

2 Locate and mark the position of the rotating laser beam on both walls using the level sensor.

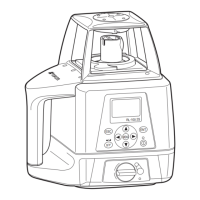

3 Turn off the instrument and move the instrument closer to wall A (1 m to 2 m /3 ft to 6 ft).

Do not change the axis orientation of the instrument. Turn the instrument on.

4 Again locate and mark the position of the rotating laser beam on both walls using the level

sensor.

5 Measure the distance between the first and second marks on each wall.

6 If the difference between each set of marks is less than ±5 mm (±7/32 of an inch), no error

exists.

If the difference between [wall A]-side and [wall B]-side exceeds ±5 mm (±7/32 of an

inch), contact your dealer or Topcon.

Minimum about 50 m/164 ft

Cone error

Datum position

Wall

A

Wall

A

Wall

B

Wall

B

Loading...

Loading...