Drive System

Maintenance

Checking the T ire Pressure

Service Interval : Before each use or daily

V ary the tire pressure for all 3 wheels, depending

upon your turf conditions, from a minimum of 83 to a

maximum of 1 10 kPa (12 psi to 16 psi).

Important: Ensure that the tire pressure for each

wheel is identical. If the tire pressure for each

wheel is different, the performance of the machine

is affected.

Checking the T orque of the

Wheel Nuts

Service Interval : After the rst 8 hours

Every 200 hours

W ARNING

Failure to maintain proper torque of the wheel

nuts could result in personal injury .

T orque the wheel nuts to the specied torque

at the specied intervals.

Wheel-nut torque specication: 108 to 122 N∙m

(80 to 90 ft-lb)

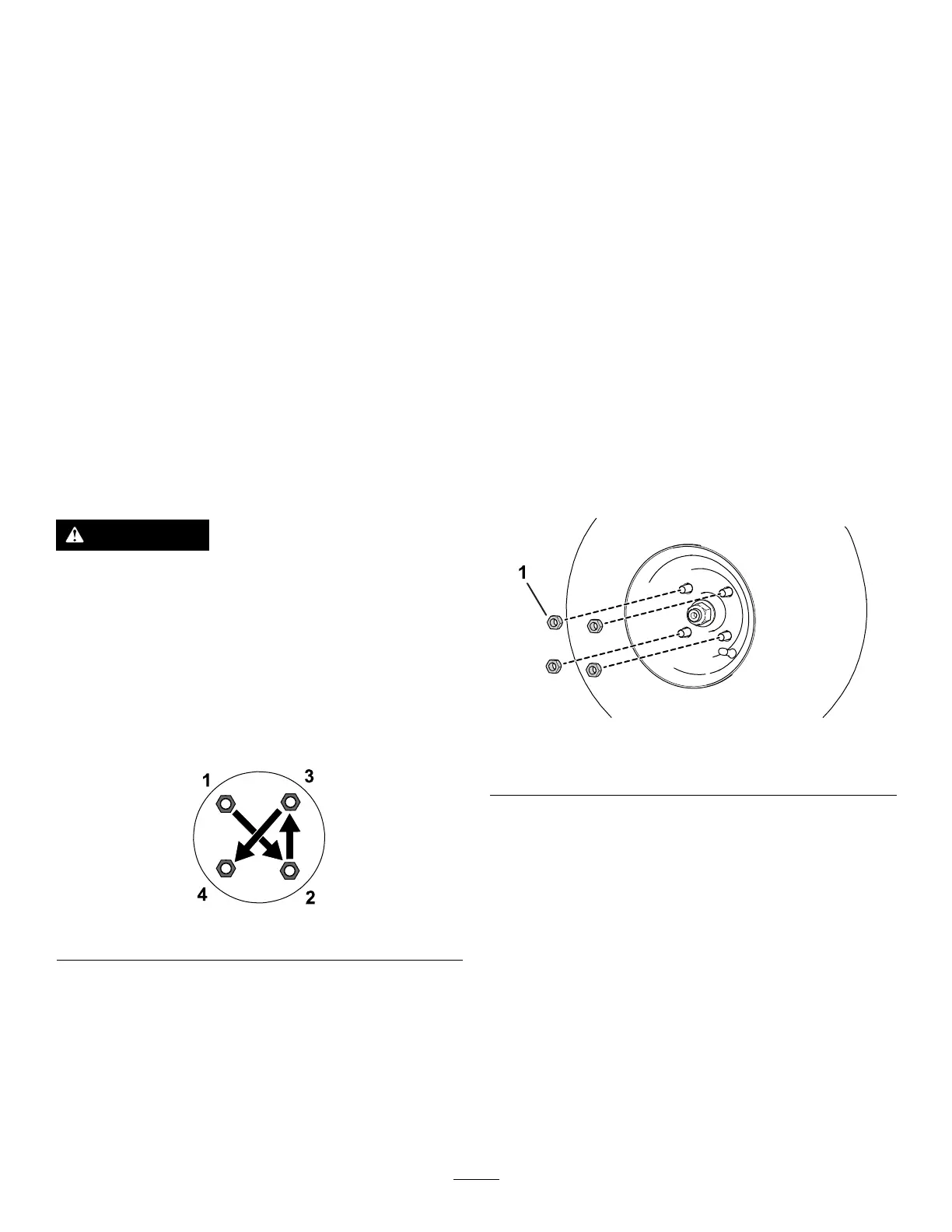

T o ensure even distribution, torque the wheel nuts in

the pattern shown in Figure 47 .

g274650

Figure 47

Changing the

T raction-Motor-Gearbox

Fluid

Service Interval : After the rst 8 hours

Every 800 hours

Fluid specication: SAE 80W90

Gearbox oil capacity: approximately 384 ml (13 oz)

1. Raise the machine; refer to Raising the Machine

( page 41 ) .

Important: The machine must be level so

that the correct amount of uid can be added

to the gearbox.

Ensure that the machine is level on the jack

stands.

2. Perform the following steps to remove the left

and right-sided tires:

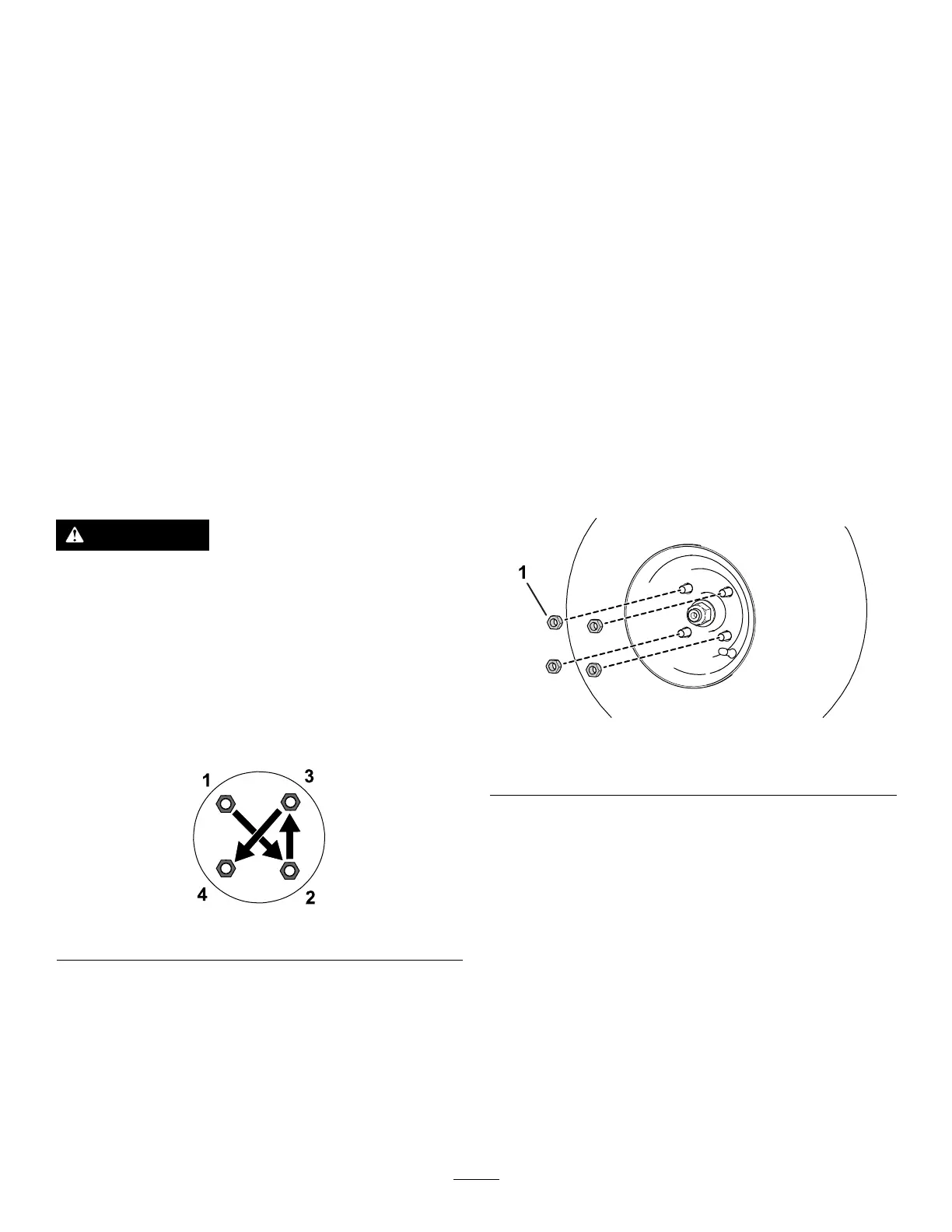

A. Loosen and remove the wheel lug nuts

( Figure 48 ).

g280226

Figure 48

1. Lug nut

B. Remove the left and right tires.

3. Place a drain pan under the wheel-motor

assembly ( Figure 49 ).

47

Loading...

Loading...