96).Increaseordecreasethecompressor

belttensionandtightenthebolt.Checkthe

deectionofthebeltagaintoensurethatthe

tensioniscorrect.

Re-tensioningtheBlade

DriveBelts

ServiceInterval:Aftertherst10hours

Every50hours

Checktheconditionandtensionofthecuttingunit

drivebeltsinitiallyafter10hoursofoperationand

every50operatinghoursthereafter.

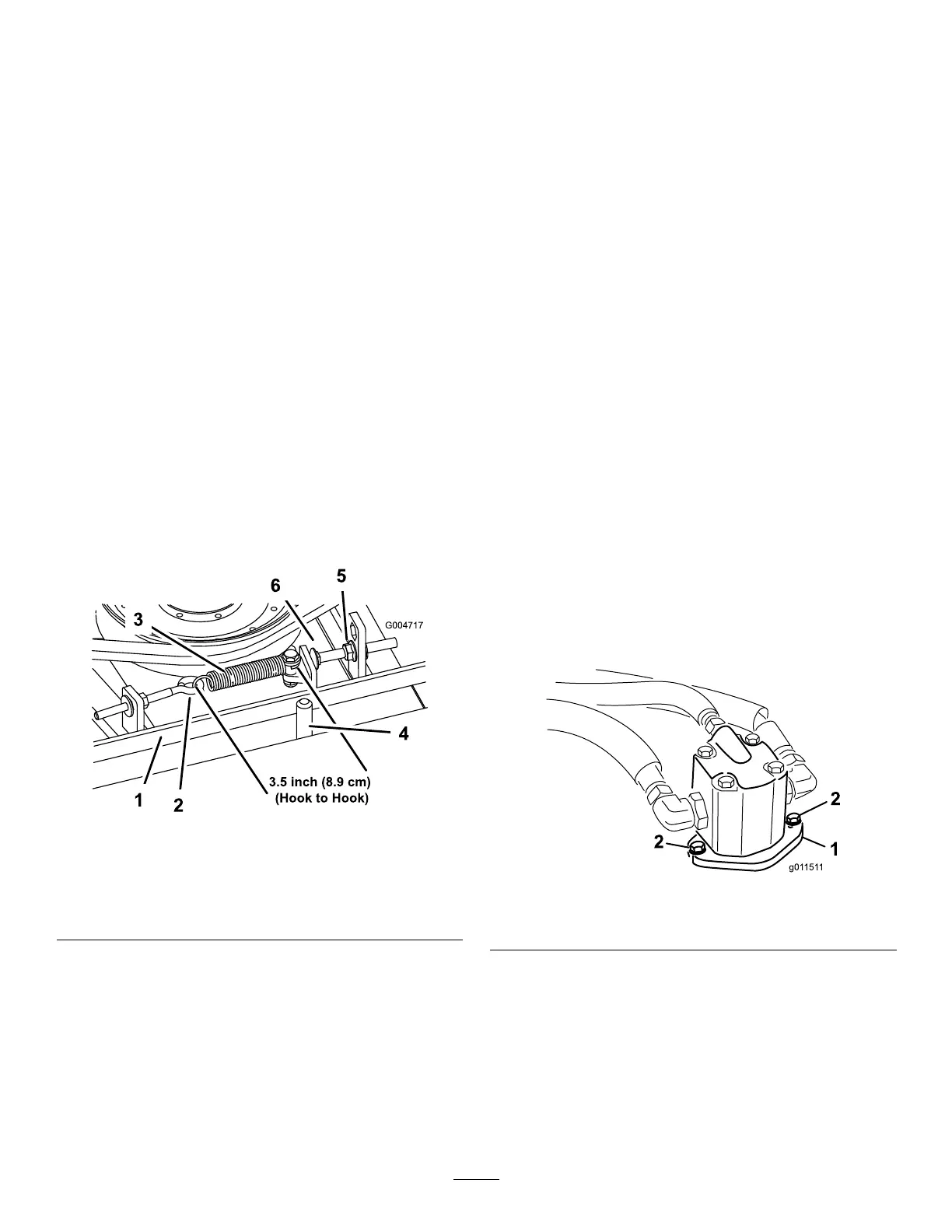

Whenproperlytensioned,theextensionspring(hook

tohook)measurementshouldbeapproximately8.9

cm±.63cm(3.50±.25inch)(inside).Oncethe

correctspringtensionisattained,adjustthestop

bolt(carriagebolt)untilthereisapproximately.32

cm±.152/.000cm(.125+.060/-.000inch)clearance

betweentheheadoftheboltandtheidlerarm(Figure

97).

Note:Makesurethebeltispositionedonthespring

sideofthebeltguide(Figure97).

g004717

Figure97

1.Belt4.Beltguide

2.Eyebolt5.Flangenut

3.Extensionspring

6.Stopbolt

ReplacingtheBladeDrive

Belt

ServiceInterval:Every800hours

Thebladedrivebelt,tensionedbythespringloaded

idlerpulley,isverydurable.However,aftermany

hoursofuse,thebeltwillshowsignsofwear.Signs

ofawornbeltare:squealingwhenbeltisrotating,

bladesslippingwhencuttinggrass,frayededges,

burnmarksandcracks.Replacethebeltifanyof

theseconditionsareevident.

1.Lowerthecuttingunittotheshopoor.Remove

thebeltcoversfromthetopofthecuttingunit

andsetthecoversaside.

2.Loosentheeyeboltallowingtheremovalofthe

extensionspring(Figure97).

3.Loosentheangenutsecuringthestopbolt

tothemountingtab.Backoffthenutenough

toallowtheidlerarmtopassbythestopbolt

(Figure97).Movetheidlerpulleyawayfromthe

belttoreleasebelttension.

Note:Ifthestopboltiseverremovedfromthe

mountingtab,makesureitisreinstalledinthe

holethatalignsthestopboltheadwiththeidler

arm.

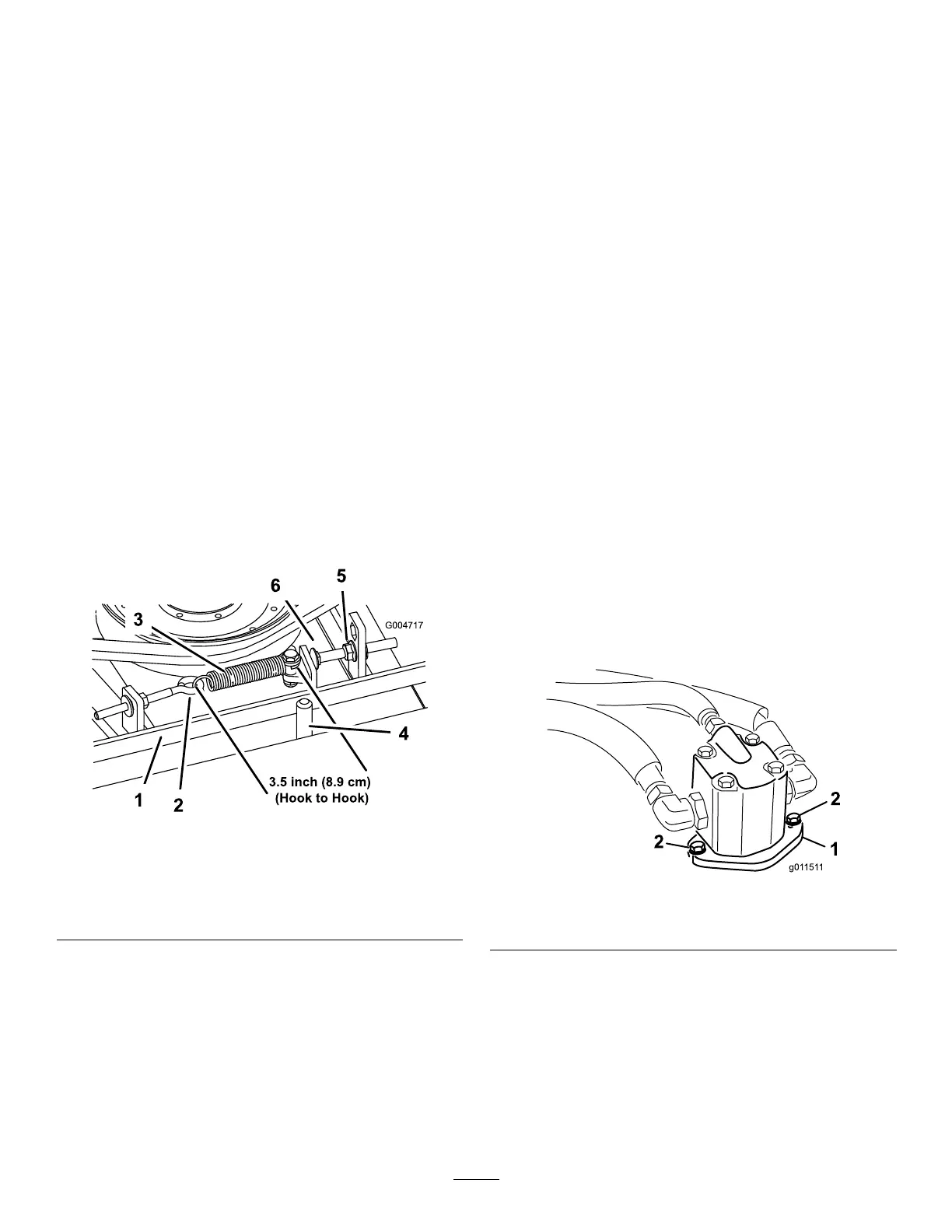

4.Removetheboltssecuringthehydraulicmotor

tothecuttingunit(Figure98).Liftthemotoroff

ofthecuttingunitandlayitontopofthecutting

unit.

g011511

Figure98

1.Hydraulicmotor2.Mountingbolts

5.Removetheoldbeltfromaroundthespindle

pulleysandidlerpulley.

6.Routethenewbeltaroundthespindlepulleys

andidlerpulleyassembly.

7.Positionthehydraulicmotoronthecutting

unitafterroutingthebeltaroundthepulleys.

Mountthemotortothecuttingunitwiththebolts

previouslyremoved.

63

Loading...

Loading...