BladeMaintenance

CheckingforaBentBlade

Afterstrikingaforeignobject,inspectthemachine

fordamageandmakerepairsbeforerestartingand

operatingtheequipment.T orqueallthespindlepulley

nutsto176to203N-m(130to150ft-lb).

1.Positionthemachineonalevelsurface.Raise

thecuttingunit,engagetheparkingbrake,put

thetractionpedalinneutral,putthePTOlever

intheOffposition,stoptheengine,andremove

theignitionkey.Blockthecuttingunittoprevent

itfromaccidentallyfalling.

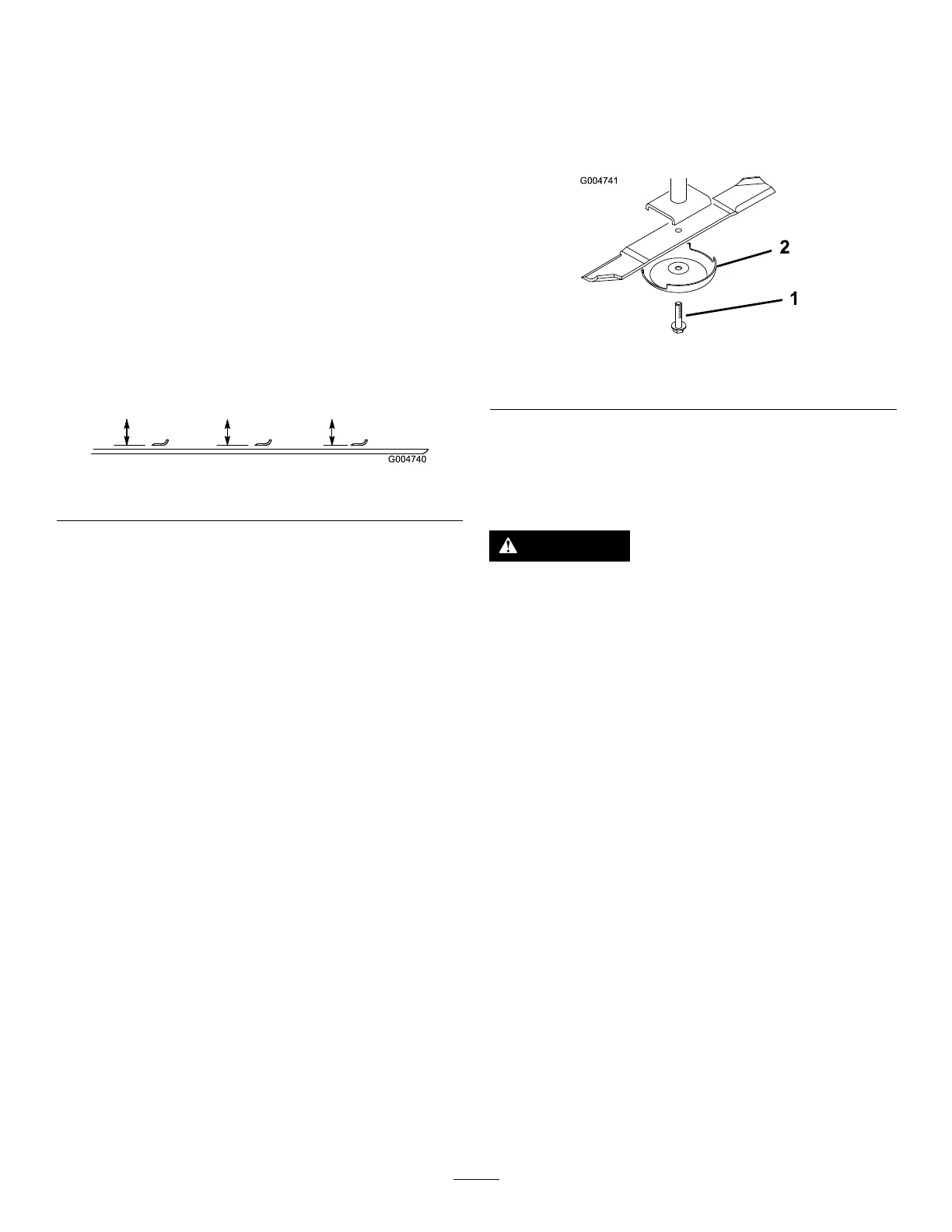

2.Rotatethebladeuntiltheendsfaceforwardand

backward(Figure111).Measurefromtheinside

ofthecuttingunittothecuttingedgeatthefront

oftheblade.Rememberthisdimension.

g004740

Figure111

3.Rotatetheoppositeendofthebladeforward.

Measurebetweenthecuttingunitandcutting

edgeofthebladeatthesamepositionasin

step2.Thedifferencebetweenthedimensions

obtainedinsteps2and3mustnotexceed

3mm(1/8inch).Ifthedimensionexceeds3

mm(1/8inch),thebladeisbentandmustbe

replaced;refertoRemovingandInstallingthe

CutterBlade.

RemovingandInstalling

theCutterBlade(s)

Theblademustbereplacedifasolidobjectishit,

thebladeisoutofbalance,orifthebladeisbent.

AlwaysusegenuineT ororeplacementbladestobe

sureofsafetyandoptimumperformance.Neveruse

replacementbladesmadebyothermanufacturers

becausetheycouldbedangerous.

1.Raisethecuttingunittothehighestposition,

engagetheparkingbrake,stoptheengine,and

removetheignitionkey.Blockthecuttingunitto

preventitfromaccidentallyfalling.

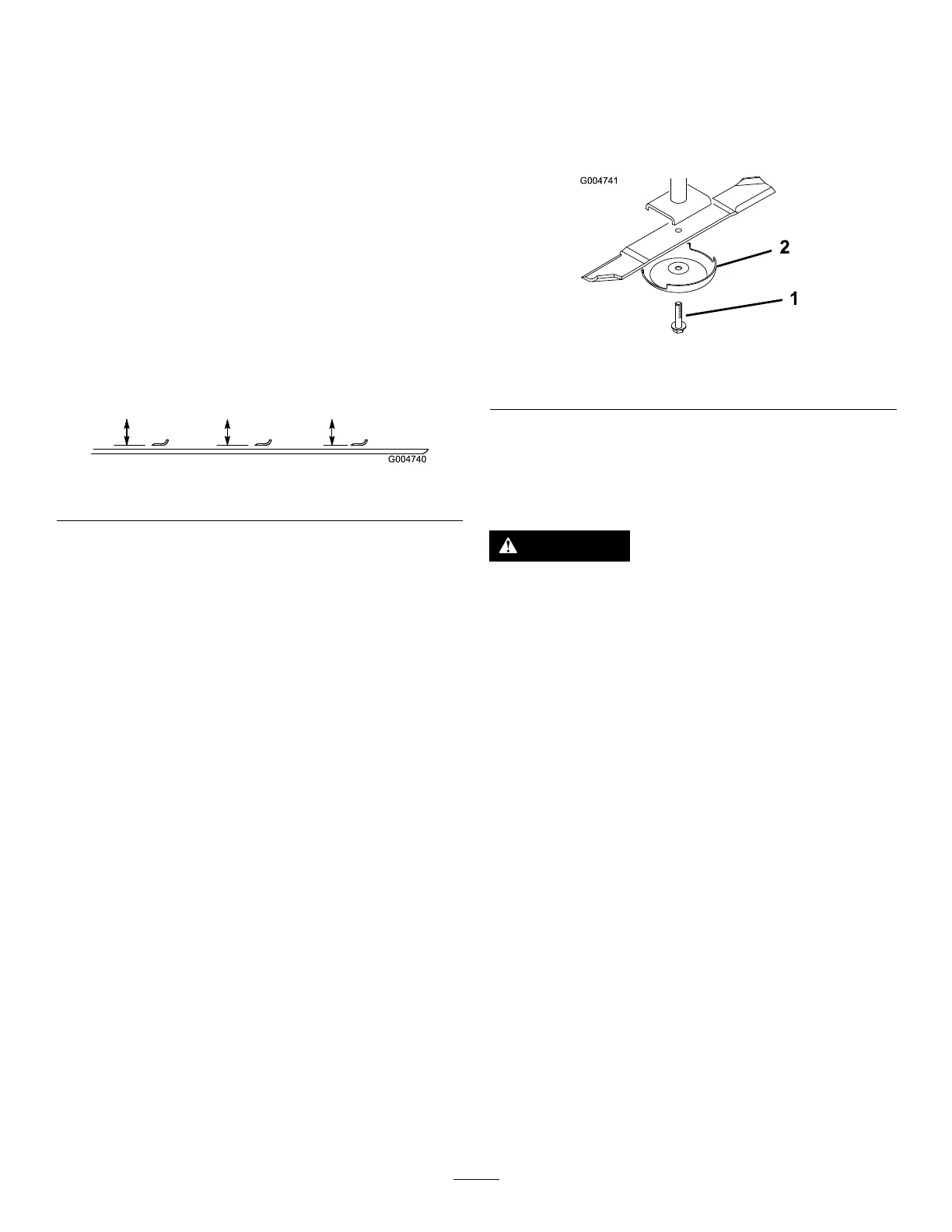

2.Grasptheendofthebladeusingaragorthickly

paddedglove.Removethebladebolt,anti-scalp

cup,andbladefromthespindleshaft(Figure

112).

3.Installtheblade,anti-scalpcup,andbladebolt.

Tightenthebladeboltto115to149N-m(85to

110ft-lb).

Important:Thecurvedpartoftheblade

mustbepointingtowardtheinsideofthe

cuttingunittoensurepropercutting.

Note:Afterstrikingaforeignobject,torqueall

thespindlepulleynutsto115to149N-m(85

to110ft-lb).

g004741

Figure112

1.Bladebolt2.Anti-scalpcup

InspectingandSharpening

theCutterBlade(s)

DANGER

Awornordamagedbladecanbreak,and

apieceofthebladecouldbethrowninto

theoperator'sorbystander'sarea,resulting

inseriouspersonalinjuryordeath.Trying

torepairadamagedblademayresultin

discontinuedsafetycerticationofthe

product.

•Inspectthebladeperiodicallyforwearor

damage.

•Nevertrytostraightenabladethatisbent

orweldabrokenorcrackedblade.

•Replaceawornordamagedblade.

Twoareasmustbeconsideredwhencheckingand

servicingthecutterblade-thesailandthecutting

edge.Bothcuttingedgesandthesail,whichisthe

turnedupportionoppositethecuttingedge,contribute

toagoodquality-of-cut.Thesailisimportantbecause

itliftsthegrassupstraight,therebyproducingan

evencut.However,thesailwillgraduallyweardown

duringoperation,andthisconditionisnormal.As

thesailwearsdown,thequality-of-cutwilldegrade

somewhat,althoughthecuttingedgesaresharp.

Thecuttingedgeoftheblademustbesharpsothat

thegrassiscutratherthantorn.Adullcuttingedge

isevidentwhenthetipsofthegrassappearbrown

andshredded.Sharpenthecuttingedgestocorrect

thiscondition.

70

Loading...

Loading...