ReplacingtheHydraulic

Filters

ServiceInterval:Every800hours

Changethe2hydraulicltersafterevery800

operatinghours,innormalconditions.

UseT ororeplacementlters(PartNo.94-2621for

theleftsideofthemachineand75-1310fortheright

sideofthemachine).

Important:Useofanyotherltermayvoidthe

warrantyonsomecomponents.

1.Positionthemachineonalevelsurface,lower

thecuttingunits,stoptheengine,engagethe

parkingbrakes,andremovetheignitionkey.

2.Cleantheareaaroundtheltermountingareas.

Placeadrainpanunderthelterandremove

thelter(Figure100).

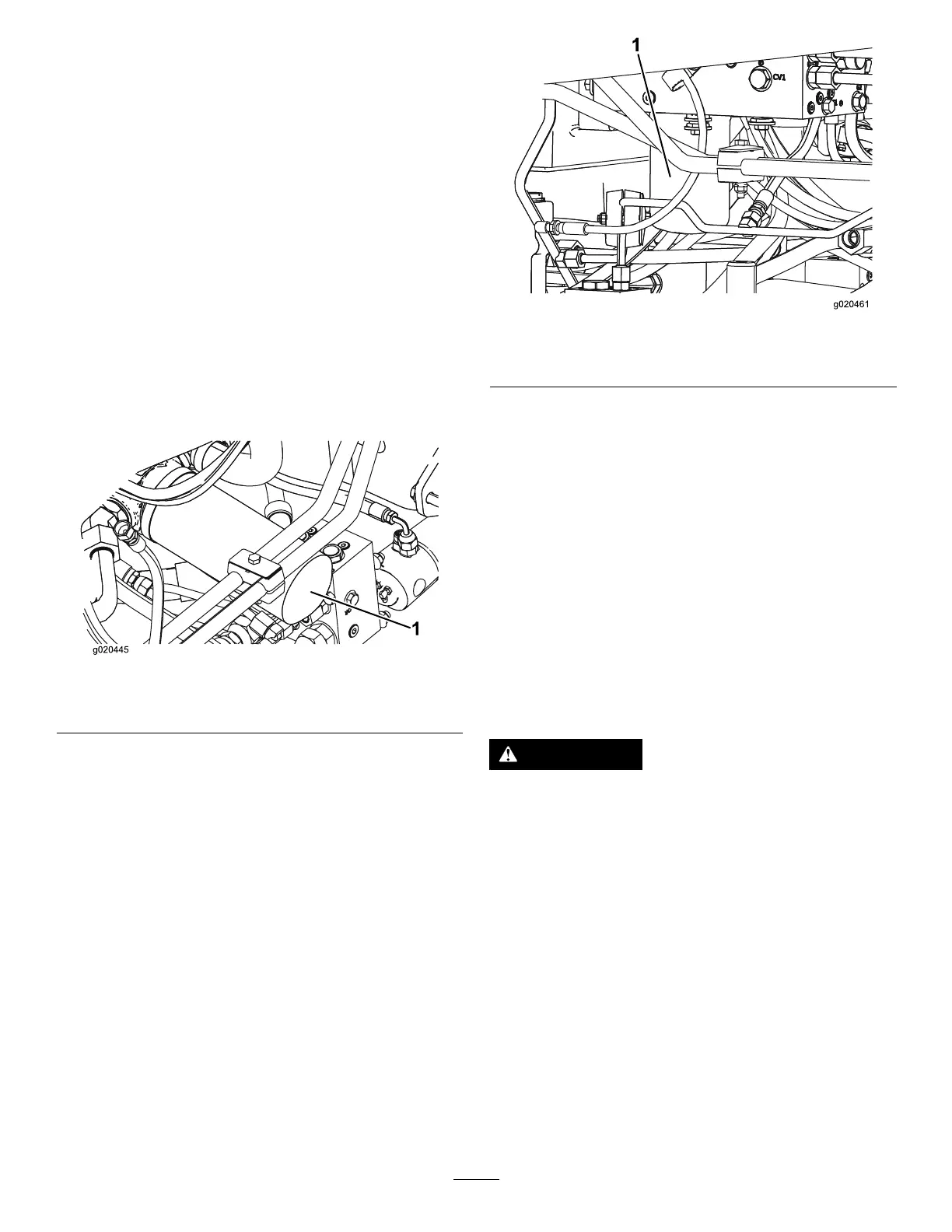

g020445

Figure100

1.Hydrauliclter

3.Lubricatethenewltergasketandllthelter

withhydraulicuid.

4.Ensurethattheltermountingareaisclean.

Screwthelteronuntilthegasketcontacts

themountingplate;thentightenthelteran

additional1/2turn.

5.Repeattheprocedureonotherlter(Figure

101).

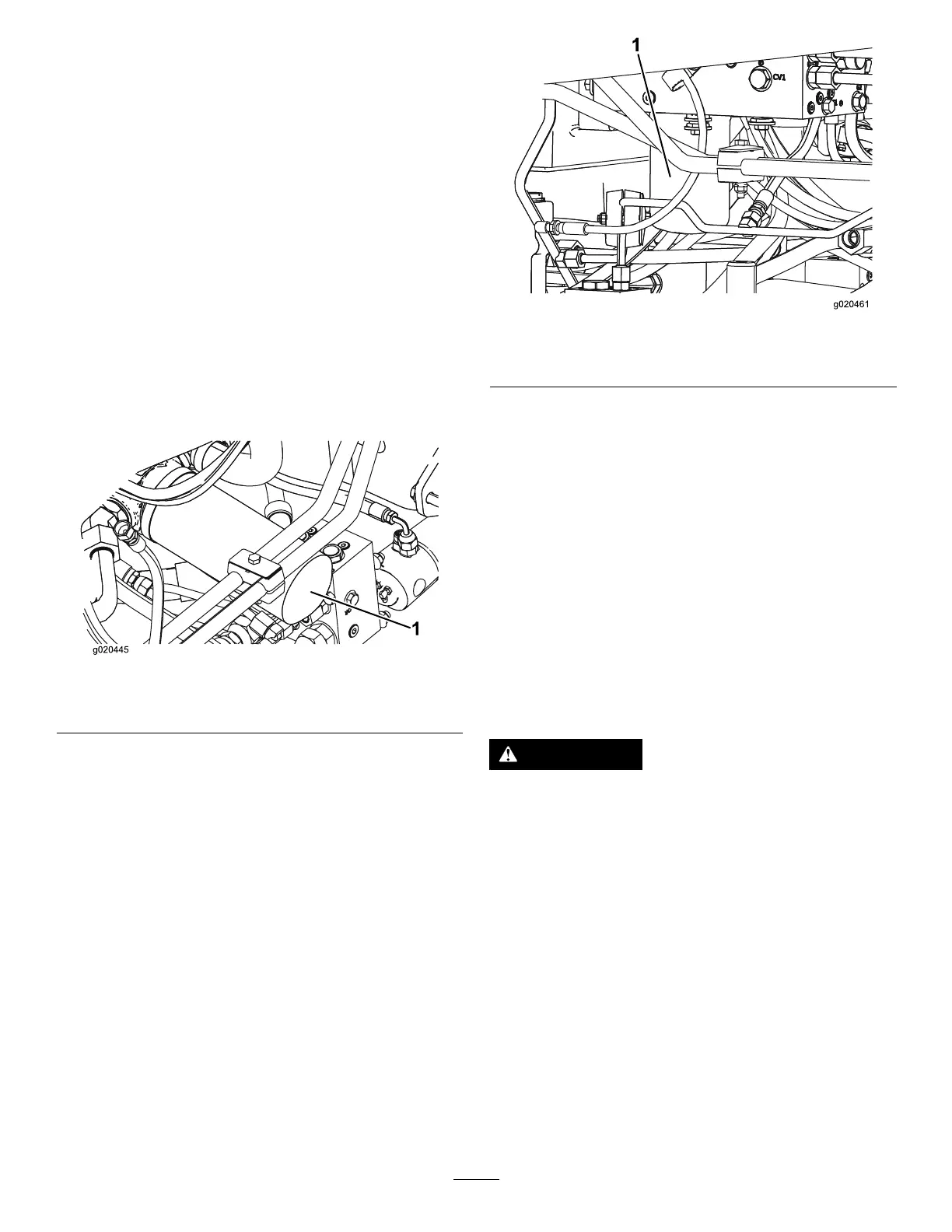

g020461

Figure101

1.Hydrauliclter

6.Oncethereservoirislled,starttheengine

andletitrunatlowidleforapproximatelytwo

minutes.Activatesteeringandraise/lower

cuttingunitsseveraltimestopurgeairfromthe

system.Stoptheengineandcheckforleaks.

CheckingtheHydraulic

LinesandHoses

ServiceInterval:Every2years

Inspectthehydrauliclinesandhosesdailyfor

leaks,kinkedlines,loosemountingsupports,wear,

loosettings,weatherdeterioration,andchemical

deterioration.Makeallnecessaryrepairsbefore

operating.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesureallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthatejecthigh

pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Seekimmediatemedicalattentionifuid

isinjectedintoskin.

65

Loading...

Loading...