WingLiftAssemblies

Wingliftcylinder(4)(Figure69)

g011502

Figure69

WingCuttingUnits

•Castorforkshaftbushing(1)(Figure70)

•Spindleshaftbearings(2each)(locatedunder

thepulley)

•Idlerarmpivotbushings(1)(locatedontheidler

arm)

g011557

Figure70

EngineMaintenance

AirCleanerMaintenance

•Checktheaircleanerbodyfordamagewhich

couldcauseanairleak.Replaceifdamaged.

Checkthewholeintakesystemforleaks,damage

orloosehoseclamps.

•Servicetheaircleanerlteronlywhentheservice

indicatorrequiresitorevery400hours(more

frequentlyinextremelydustyordirtyconditions).

Changingtheairlterbeforeitisnecessaryonly

increasesthechanceofdirtenteringtheengine

whenthelterisremoved.

•Besurethecoverisseatedcorrectlyandseals

withtheaircleanerbody.

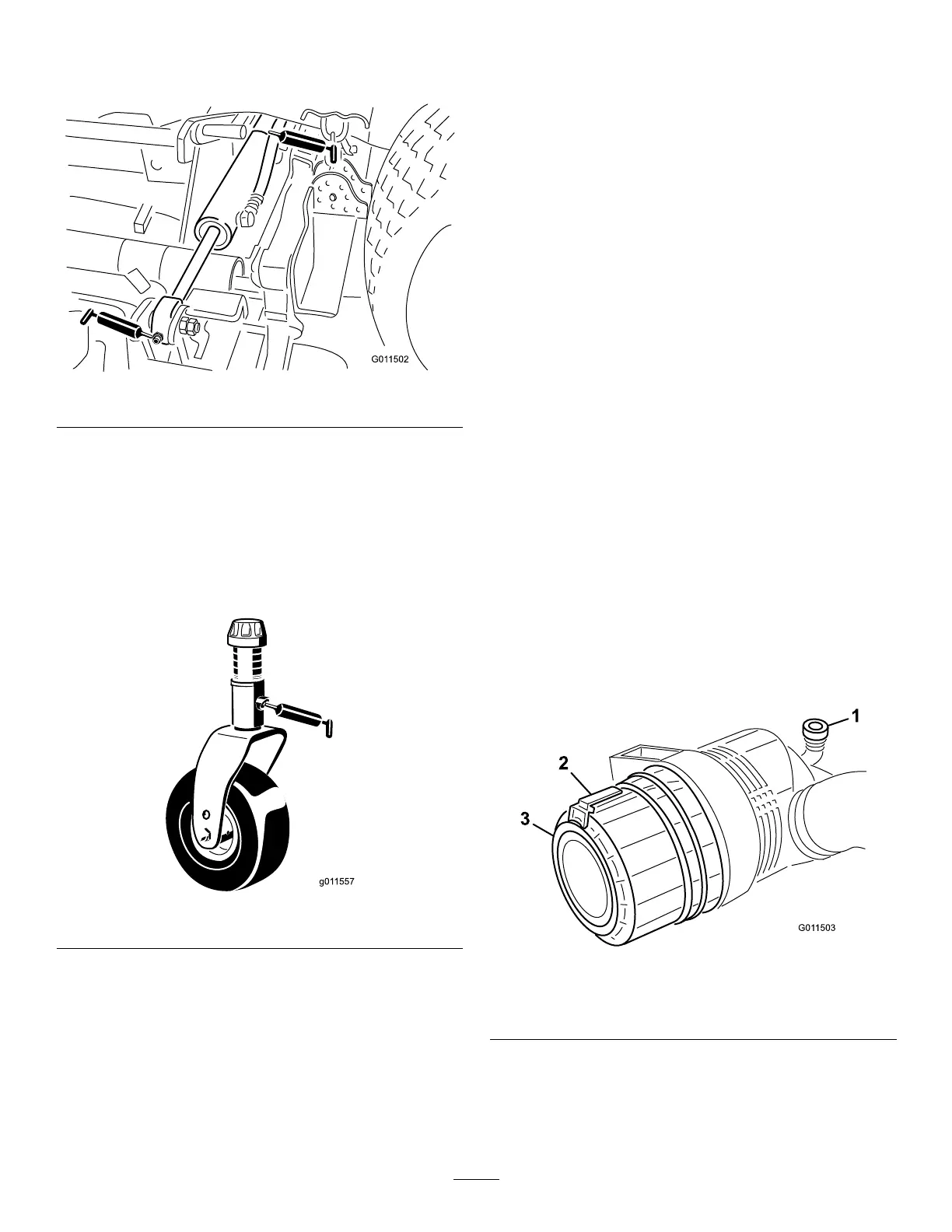

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Every50hours

Every400hours

1.Pullthelatchoutwardandrotatetheaircleaner

covercounterclockwise(Figure71).

2.Removethecoverfromtheaircleanerbody.

Beforeremovingthelter,uselowpressureair

(40psi,cleananddry)tohelpremovelarge

accumulationsofdebrispackedbetweenoutside

ofprimarylterandthecanister.Avoidusing

highpressureairwhichcouldforcedirtthrough

thelterintotheintakearea.Thiscleaning

processpreventsdebrisfrommigratingintothe

intakewhentheprimarylterisremoved.

g011503

Figure71

1.Aircleanerindicator3.Aircleanercover

2.Aircleanerlatch

3.Removetheprimarylter(Figure72).Cleaning

oftheusedelementisnotrecommendeddue

tothepossibilityofdamagetotheltermedia.

Inspectthenewlterforshippingdamage,

checkingthesealingendofthelterandthe

52

Loading...

Loading...