Maintenance

MaintenanceSafety

•Whileperformingmaintenanceonthemachine,

someonecouldstarttheengine.Accidental

startingoftheenginecouldseriouslyinjureyouor

others.Removethekeyfromtheignitionswitch,

engageparkingbrake,andpullthewire(s)offthe

sparkplug(s)beforeyoudoanymaintenance.

Also,pushthewire(s)asidesothatitdoesnot

accidentallycontactthesparkplug(s).

•Theenginecanbecomeveryhot.T ouchingahot

enginecancausesevereburns.Allowtheengine

tocoolcompletelybeforeservicingorrepairing

aroundtheenginearea.

•Parkthemachineonlevelgroundandallowitto

cool.Neverallowuntrainedpersonneltoservice

themachine.

•Disengagethesprayorclosethespreadergate,

settheparkingbrake,shutofftheengine,and

removethekeyordisconnectthespark-plugwire.

Waitforallmovementtostopbeforeadjusting,

cleaning,orrepairingthemachine.

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Connectpositiveterminalrstandnegative

terminallast.

•Relievethepressurefromthespraysystembefore

servicingthemachine.

•Emptythetankand/orhopperbeforetiltingthe

machineformaintenanceandbeforestorage.

•Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidaccidentally

injectedintotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwiththis

formofinjury;otherwise,gangrenemayresult.

–Ifequipped,ensurethatallhydraulicuid

hosesandlinesareingoodconditionand

thatallhydraulicconnectionsandttingsare

tightbeforeapplyingpressuretothehydraulic

system.

–Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

–Usecardboardorpaper,notyourhands,to

ndhydraulicleaks.

–Safelyrelieveallpressureinthehydraulic

systembyplacingthemotion-controllevers

inneutralandshuttingofftheenginebefore

workingonthehydraulicsystem.

•Raisingthemachineforserviceormaintenance

relyingsolelyonmechanicalorhydraulicjacks

couldbedangerous.Themechanicalorhydraulic

jacksmaynotbeenoughsupportormay

malfunction,allowingthemachinetofallandcause

possibleinjury.Donotrelysolelyonmechanical

orhydraulicjacksforsupport.Useadequatejack

standsorequivalentsupport.

•Carefullyreleasethepressurefromcomponents

withstoredenergy.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswhile

theengineisrunning.Ifthemaintenanceor

adjustmentprocedurerequirestheenginetobe

runningandcomponentsmoving,useextreme

caution.

•Contactwithmovingpartsorhotsurfacesmay

causepersonalinjury.Keepyourngers,hands,

andclothingclearofrotatingcomponentsandhot

surfaces.

•Checkallboltsfrequentlytomaintaintheirproper

tightness.

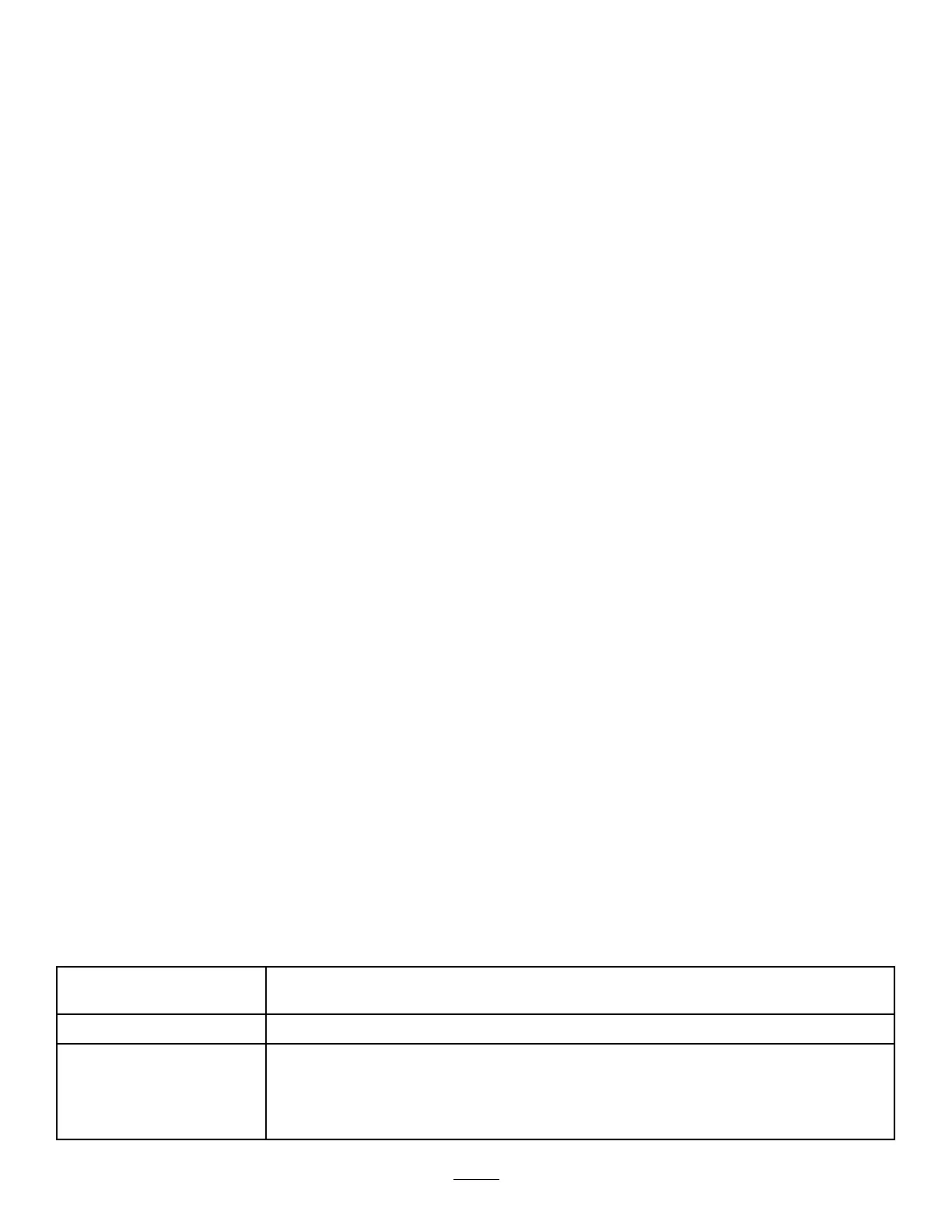

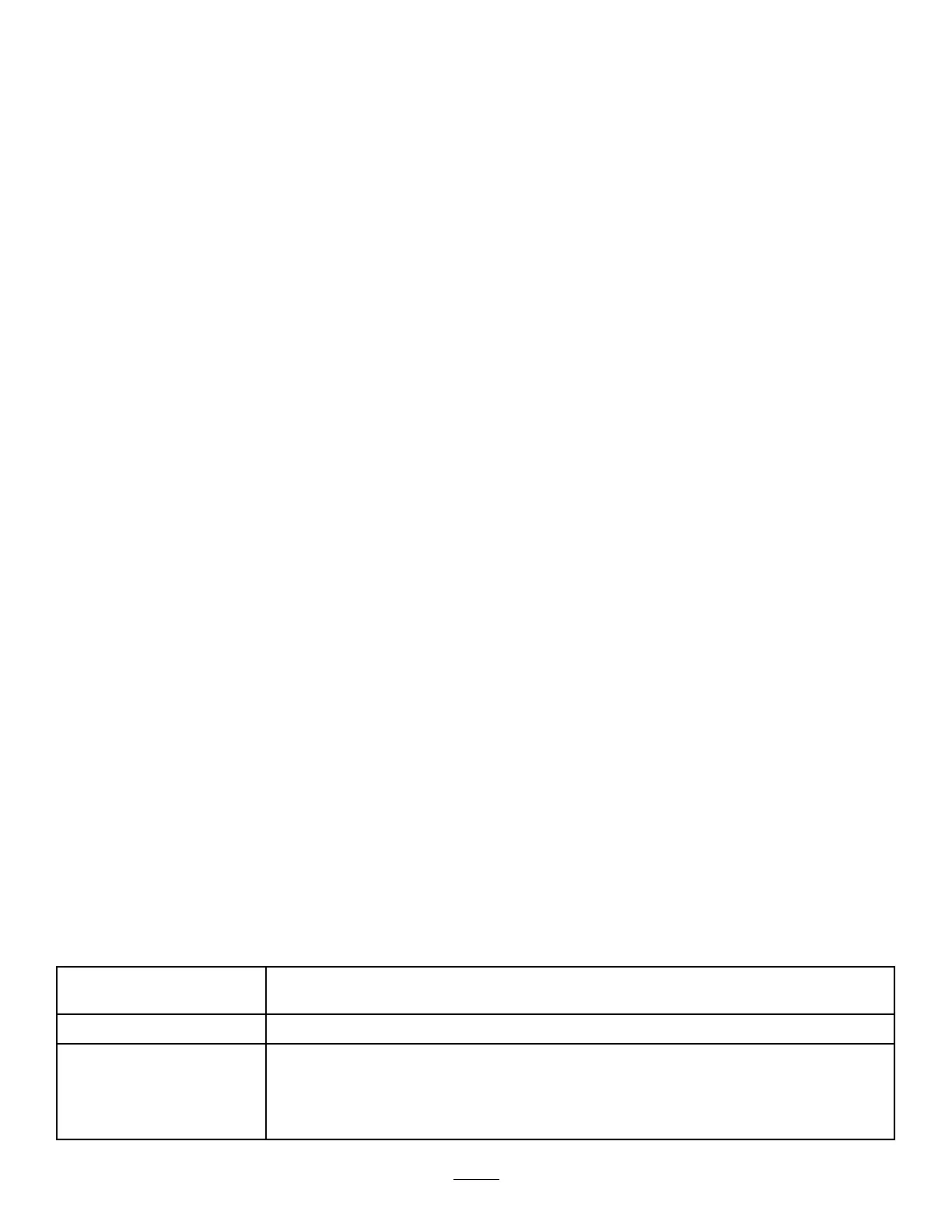

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst10hours

•Changetheengineoil.

Beforeeachuseordaily

•Checkthesafetyinterlocksystem.

•Testthestarterinterlock.

•Checkaircleaner;replaceifdirty.(Mayneedmoreoftenundersevereconditions.)

•Checktheengine-oillevel.

•Checkthemachineforloosehardware.

49

Loading...

Loading...