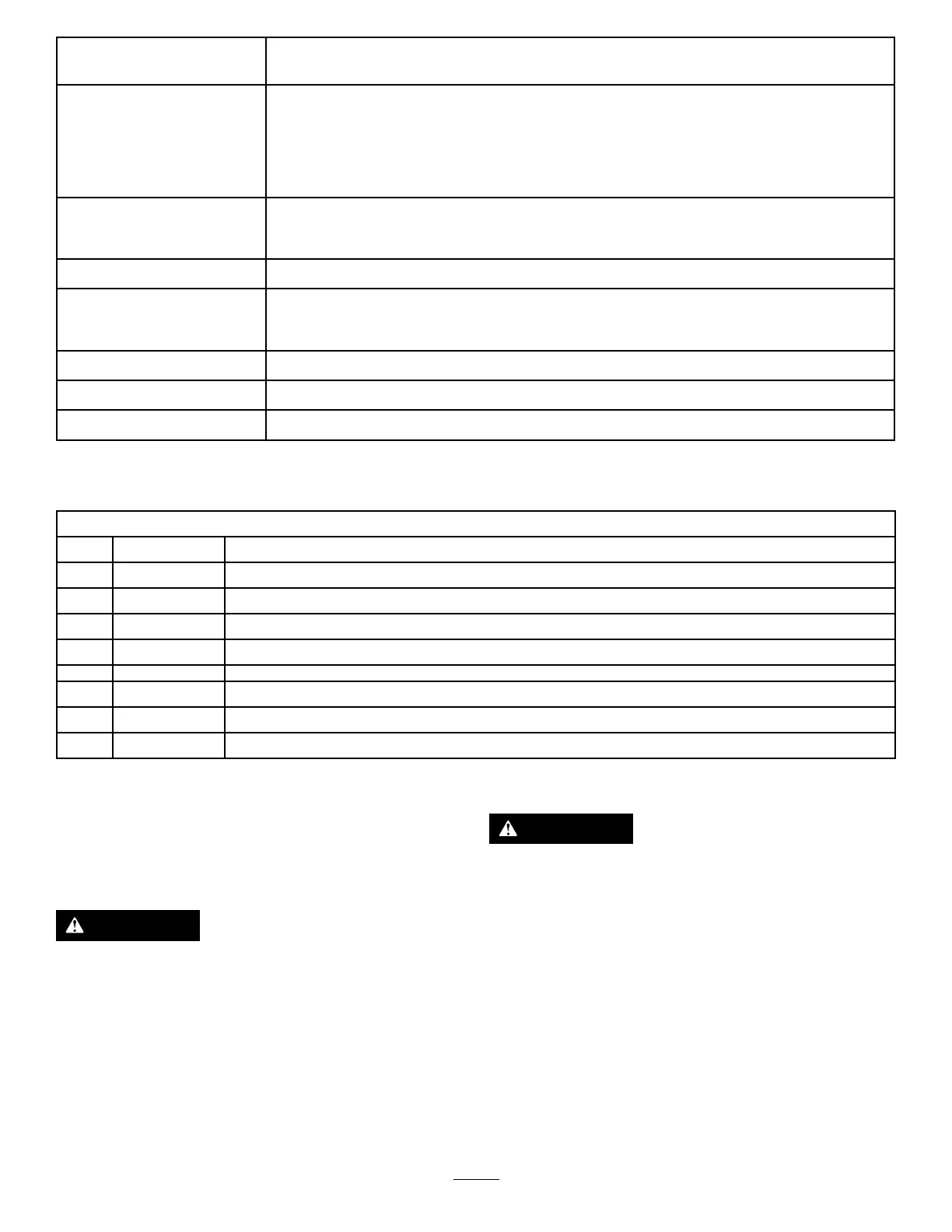

MaintenanceService

Interval

MaintenanceProcedure

Aftereachuse

•Cleanandlubricatethespreader.

•Cleanthesprayertank.

•Cleanthestrainer.

•Cleanthesprayernozzles.

•Cleantheengineandtheexhaustsystemarea.

•Cleanthegrassanddebrisbuildupfromthemachine.

Every50hours

•Checkthepressureinthetires.

•Servicethetransaxle.

•Checksprayersystem.

Every80hours

•Removetheengineshroudsandcleanthecoolingns.

Every100hours

•Lubricatethegreasettings.

•Replacethedualelementairlter.

•Changetheengineoil(moreoftenunderseverecondition).

Monthly

•Checkthebattery.

Yearly

•Torquetheaxlebolts.

Yearlyorbeforestorage

•Preparethemachineforstorage.

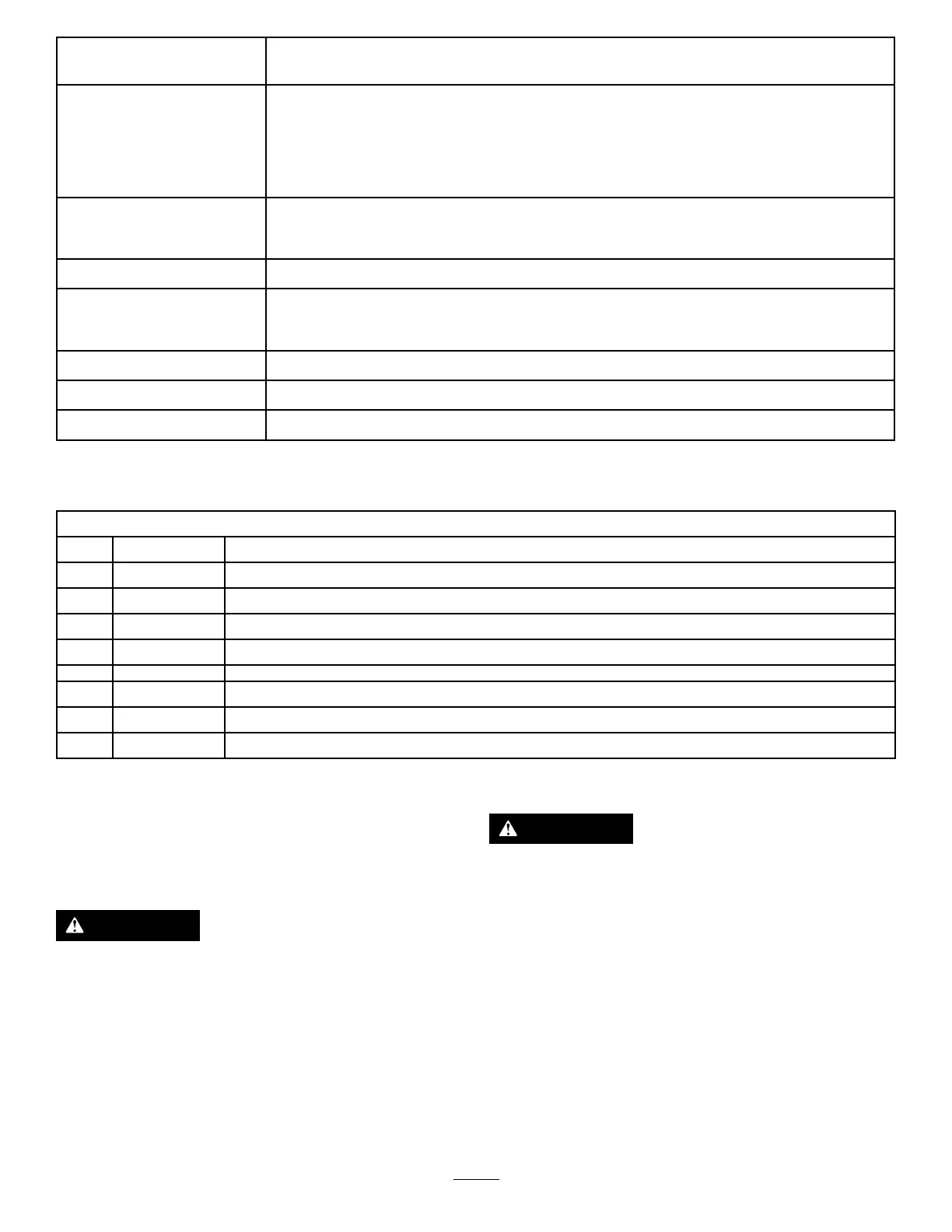

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

1

2

3

4

5

6

7

8

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

Pre-Maintenance

Procedures

CAUTION

Ifyouleavethekeyintheswitch,someone

couldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyou

performanymaintenance.

CAUTION

Raisingthemachineforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.The

mechanicalorhydraulicjacksmaynotbe

enoughsupportormaymalfunctionallowing

themachinetofall,whichcouldcauseinjury.

Donotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

50

Loading...

Loading...