2. SUPPLY SPECIFICATIONS EO10-33016A

2.1 Media

2- 2

NOTES:

1. To ensure print quality and print head life use only TOSHIBA

TEC specified media.

2. The ratio of a label length to a gap length must be a minimum of

3 to 1 (3:1).

3. Backing paper must be wider than a label; the distance between

the edge of the backing paper and that of a label should be at

least 1.5 mm.

4. For the backing paper Glassine paper 7K or 8K white or

equivalent should be used. Also, the light transmission rate of

the backing paper should be 22% or above.

5. When cutting media, fine adjust a cut position properly. (See System Mode Manual, Section 2.3.)

6. If a printing stop position (strip position) is improper, use a procedure for the strip position fine adjustment to

correct the position. (See System Mode Manual, Section 2.3.)

7. When a gap length is 5 mm or mover, first set a label length to the maximum (= label pitch – 2mm), then,

fine adjust a strip position using a Strip position fine adjustment procedure. (See System Mode Manual,

Section 2.3.)

8. If the top edge of media is curled onto the platen during the cut issue, set the Forward Wait parameter in the

system mode to ON. (See System Mode Manual, Section 2.2.)

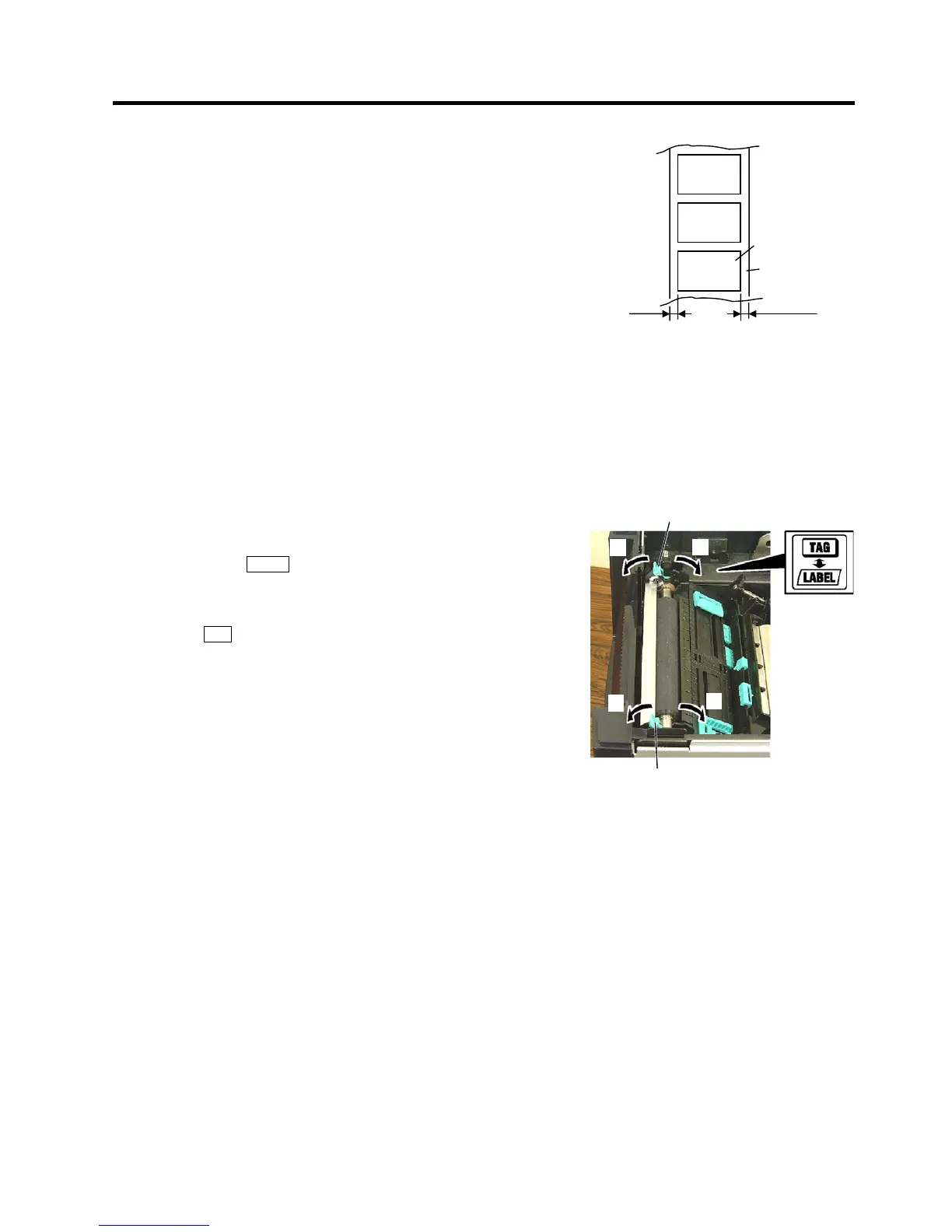

9. When using a label stock, or tag paper with a thickness of 150

µ

m

(0.15mm) or less, move the Head Position Levers toward the

printer front (c

LABEL ). If clear print cannot be obtained, move

the levers opposite.

When using tag paper with a thickness of exceeding 150

µ

m

(0.15mm), move the Head Position Levers toward the printer

back (d

TAG ). If clear print cannot be obtained, move the levers

opposite.

10. Thermal paper used for the direct thermal printing must not have

the specifications which exceed Ca

2+

, K

+

, Na

+

800 ppm, K

+

250

ppm, and Cl

–

500 ppm.

11. Avoid using media containing SiO

2

or talc which wears the print

head protection layer.

12. Ink used for pre-printing the media should not contain hard substances such as carbonic calcium (CaCO

3

)

and Kaolin (Al

2

O

3

, 2SiO

2

, 2H

2

O).

13. Use of the tag paper of 25 mm to 50 mm in width and 171

µ

m to 263

µ

m in thickness may shorten the platen

life.

14. When using a label stock in cut mode, be sure to cut the gaps. Cutting labels will cause the glue to stick to

the cutter, which may affect the cutter performance and shorten the cutter life.

15. To make tearing off a label easier, set the Auto Forward Wait function (Forward Wait parameter) to ON in

the system mode (See System Mode Manual, Section 2.2). Doing so will cause the last label printed to be

fed and stopped past the strip shaft. However, if a next label is issued without tearing off the label on the

strip shaft, the label may peel while it is fed backward, causing a printer failure.

1.5 mm or more

1.5 mm or more

Label

Backing Paper

c

Loading...

Loading...