INSTALLATION

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195

th

Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

26

Cables must have crimped and/or soldered copper compression lugs unless aluminum mechanical

lugs are used. We suggest using high quality UL listed Trace Engineering battery cables. These

cables are available in a specific assortment of sizes from 1 ½ to 10 feet, and in 2/0 or 4/0 AWG.

They are color-coded and have pressure crimped, sealed ring terminals. Contact your Trace dealer

to order.

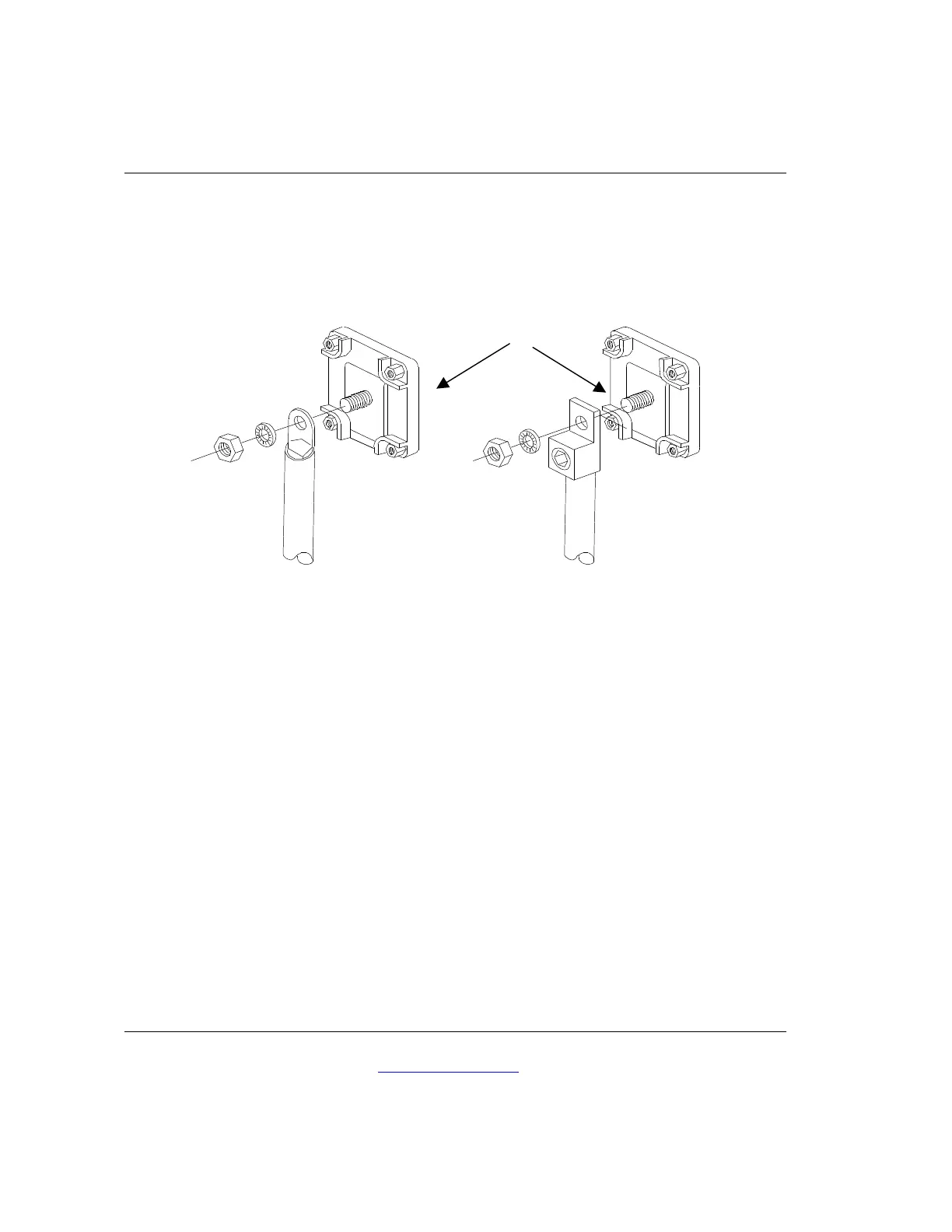

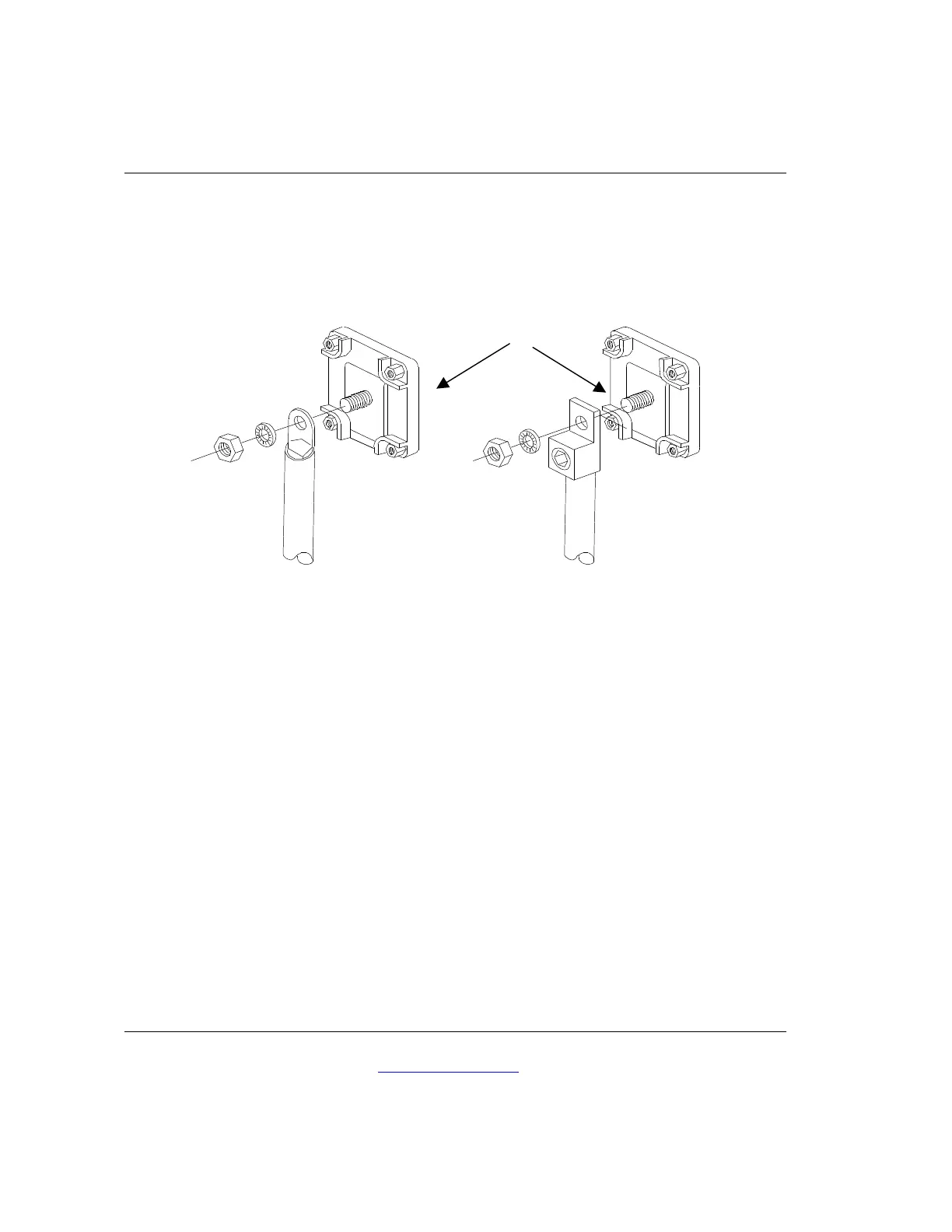

Figure 2, Battery to Inverter Cable Connection

.

Figure 2, Battery to Inverter Cable Connection illustrates proper connections for the Legend Series II

inverter/chargers. Points of caution are:

ü Do not connect the battery negative (-) terminal to the vehicle chassis; connect it to the

battery negative terminal of the inverter.

ü Do not connect the DC load negatives to the battery negative (-), connect only to the

chassis ground terminal on the inverter or to the vehicle chassis.

These connections are necessary in order for the RC7 remote control fuel gauge to work properly.

All current into or out of the battery must pass through the internal shunt, which is between the

chassis ground and battery negative terminals.

2/0 Copper Compression Lug

2/0 Aluminum Mechanical Lug

Do not place anything between

battery cable lug and terminal

surface. Assemble exactly as shown

Loading...

Loading...