Filling the hydraulic circuit

WARNING! The water used to ll the hydraulic

circuit must be ltered.

WARNING! Filling the hydraulic circuit must only

be carried out exclusively by a qualied hydraulic

technician.

WARNING! Before carrying out any type of

intervention, disconnect the power supply.

Filling the primary circuit

WARNING! The primary circuits must be equipped

with mechanical lters.

WARNING! Check that all of the shut off valves

are closed.

Open the drain valve of the primary circuit and regulate the

pressure switch to 5 bar;

bleed the air from the circuits;

turn on the primary circulation pumps;

clean the circuits leaving the pumps on; check for any loss

from the primary circuits.

Filling the hydraulic circuits of the conditioners

WARNING! Clean the primary circuits before

lling the conditioners.

WARNING! Check that all of the bleeding valves

on the conditioners are closed.

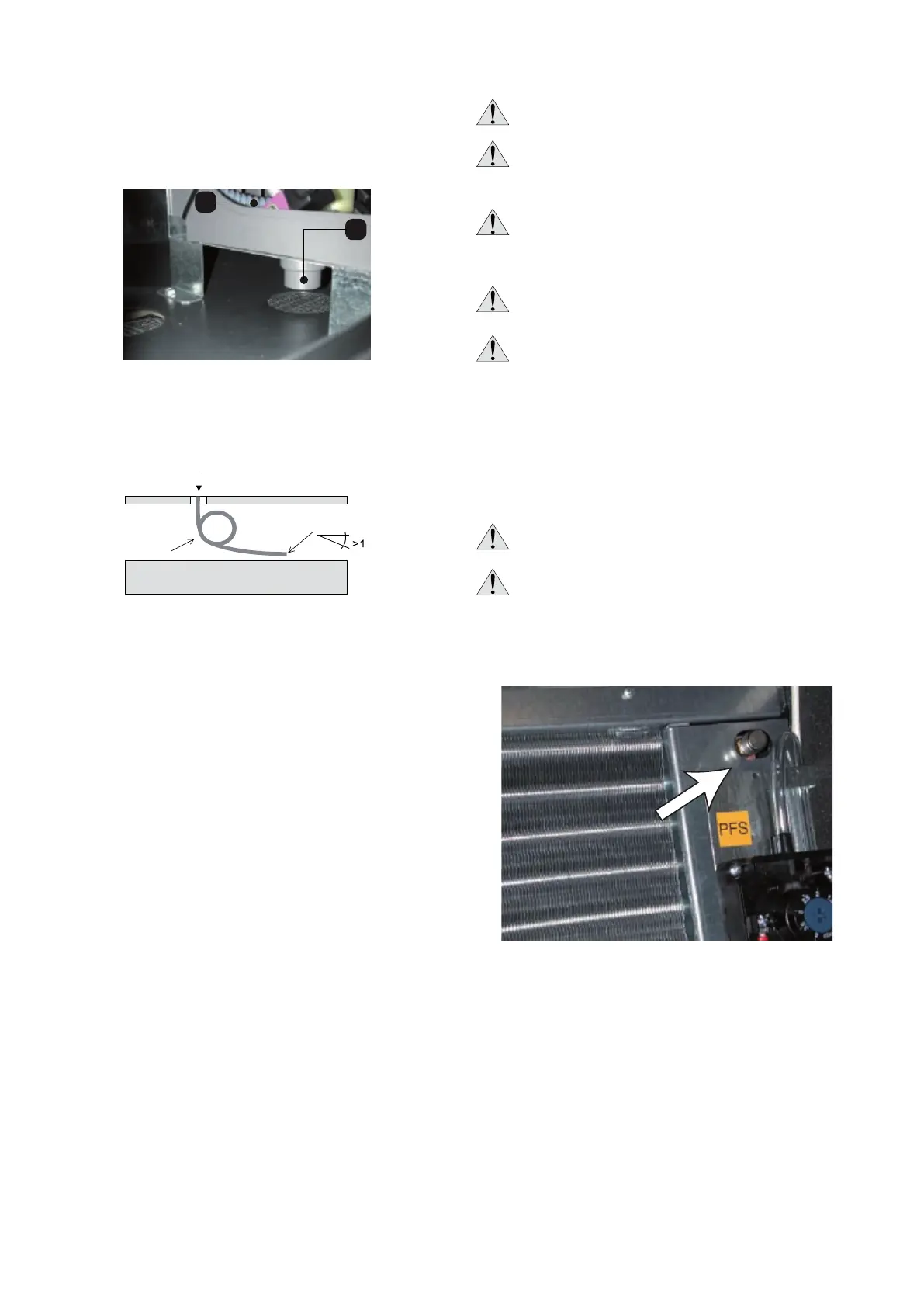

Open the shut off valves of the conditioner;

Open the bleeding valve (on the upper part of the cooling

coil) and wait for the water to come out.

Maintain a minimum slope of 1% downstream of the

siphon.

Once the connections have been made, pour water into

the condensate collection tray of the Jupiter unit and in

the condensate collection tray of the humidier until both

siphons are full.

Hydraulic connections

For all hydraulic connections (except for the condensate

drain) it is recommended to use the following:

- exible hoses to avoid the transmission of vibrations

and to allow the unit to be moved;

- three piece joints near the connections;

- shut off valves to isolate the unit from the water circuit:

if possible, use full sphere valves to minimise the

pressure drop.

Check that the chilled water pipe sizes and the circulating

pump characteristics are adequate: an insufcient water

ow affects the performance of the unit.

Check that the water ow directions are respected.

Insulate all of the chilled water pipes with closed cell

insulating material (e.g.: Armaex or equivalent) to avoid

condensation; the insulation must allow accessibility to the

valves and three piece joints.

Check that the hydraulic circuits (both chilled and hot

water) are fed with a maximum water pressure of 6 bar: to

this purpose the installer must install a safety valve in the

hydraulic with a set point of not more than 6 bar.

The minimum and maximum water temperatures inside the

unit (for the chilled water circuit and the post- heating with

hot water) are: 5°C ÷ 90°C.

The maximum amount of ethylene glycol is 50%.

Connect the drainage tube of the unit to the collection tray

(U4) of the humidier.

Connect the drainage tube of the humidier (U7) to the

drains of the building using a rubber or plastic tube, which

is resistant to high temperatures (minimum 100 °C) with an

internal diameter of 22 mm.

SDW*-SUW* 0151-0251 0331-0351-0501-0601

Ingresso acqua

condensatore

1/2” 1”

Uscita acqua

condensatore

1/2” 1”

37

38

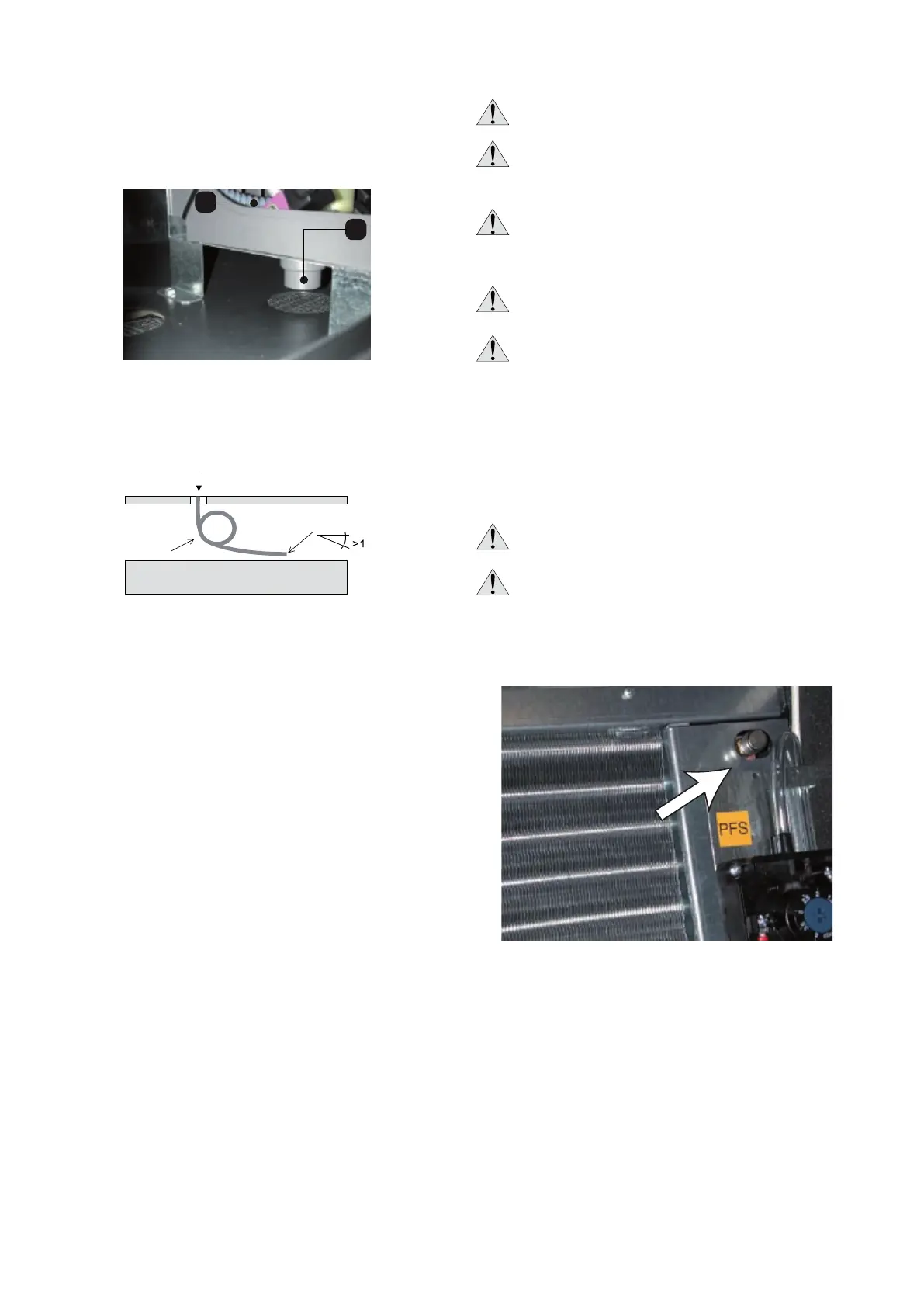

Drain

%

Siphon

Minimum slope

The external drainage tube must be siphoned to avoid

unpleasant odours and an overow of the water from the

tray of the humidier.

Maintain a minimum slope of 1% downstream of the

siphon.

U7

U4

Drain

Siphon

Minimum slope

Loading...

Loading...