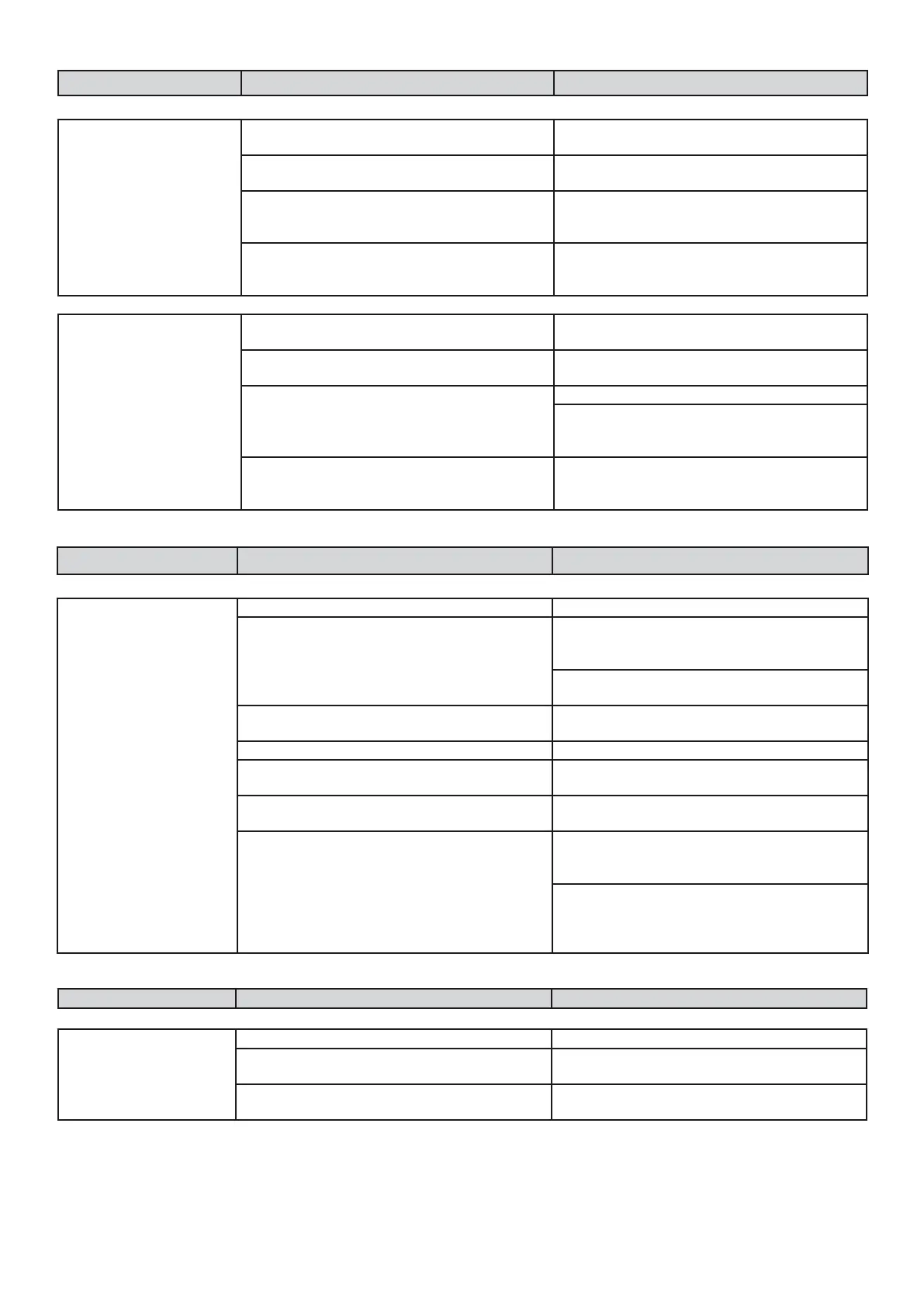

HUMIDITY CONTROL

FANS

ELECTRIC HEATERS

PROBLEM POSSIBLE CAUSE CHECK/CORRECTIVE ACTION

ROOM HUMIDITY TOO

HIGH

A) The parameter settings on the control panel

are not correct.

See control panel instruction manual.

B) The latent load is higher then expected.

Check the latent load, fresh air conditions and

volume; external air inltration.

C) Control system not working.

See: Control system user instruction manual;

check the panel and/or the probe are working

properly.

D) The chilled water is not sufciently cold for the

dehumidication function (in energy saving and

twin cool units).

Lower the chilled water temperature until

condensate is present on the surface of the coil.

ROOM HUMIDITY TOO

LOW

A) The parameter settings on the control panel

are not correct.

Check the room humidity settings (see control

panel instruction manual).

B) The latent load is lower than expected.

Check the latent load, fresh air conditions and

volume; external air inltration.

C) The humidier doesn’t work.

1) Check the water supply pressure.

2) Check the function of the manual control

system and of the steam production group (see

panel instruction manual).

D) The control system does not work.

See the control panel instruction manual; check

that the control panel and/or sensors work

properly.

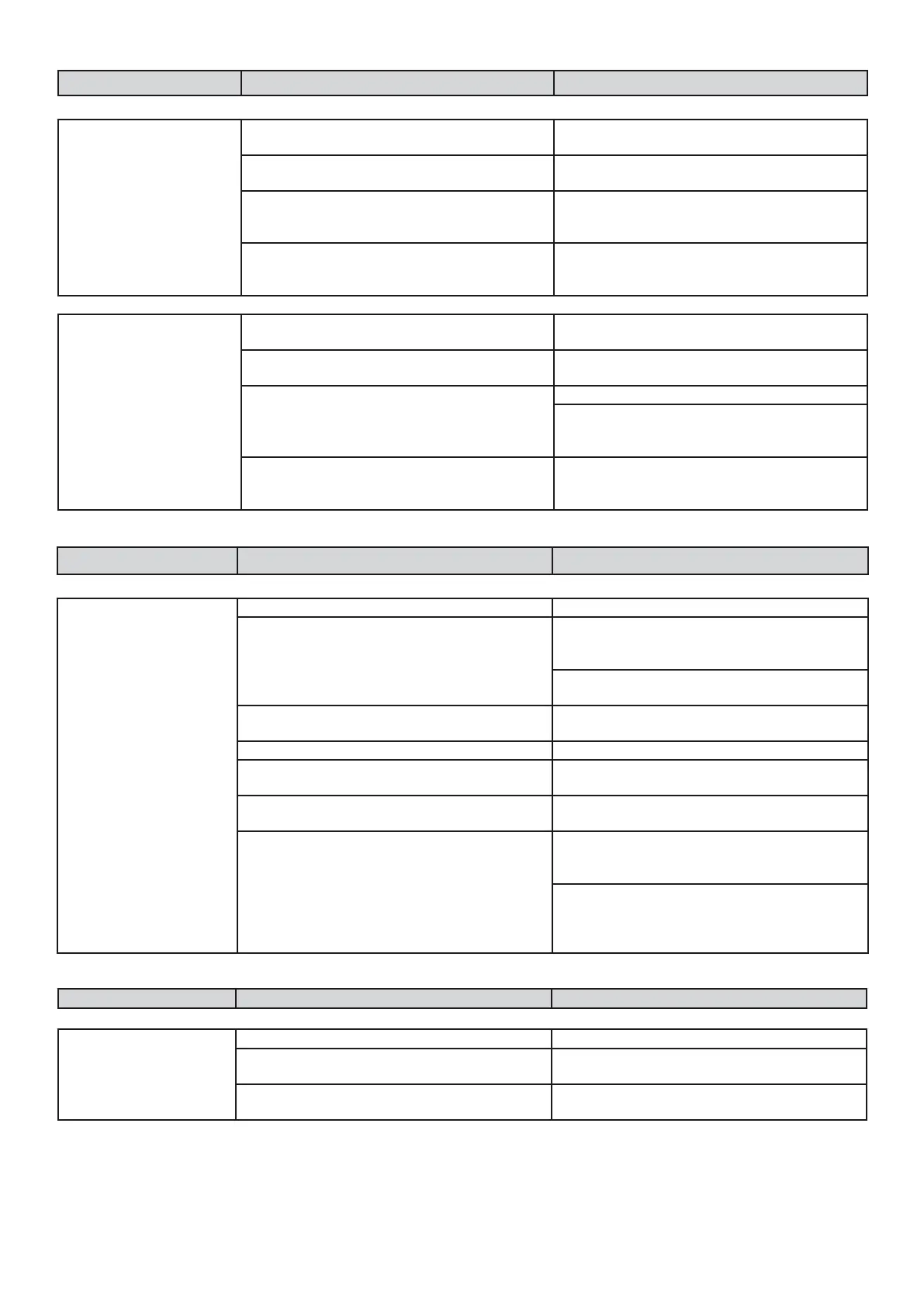

PROBLEM POSSIBLE CAUSE CHECK/CORRECTIVE ACTION

ABSENT OR LOW AIR

FLOW

A) There is no power to the fans. Check the power supply to the fans

B) The lter is blocked (possible intervention of

the dirty lters alarm).

1) Shake the dust out of the cartridge and clean

with a vacuum cleaner. Replace the lter if it is

completely blocked.

2) Check the correct setting of the dirty lter

pressure switch PFS.

C) Fans rotating in the wrong direction.

Reverse input phases and check if fans are

rotating in the correct direction

D) The air ow is obstructed. Check paragraph “AIR DISTRIBUTION”

E) The fans’ thermal protection intervenes.

Check the resistance of the fan motor windings.

Re-set then measure the voltage and absorption.

F) Fan speed regulator not set correctly.

See paragraph FAN SPEED ADJUSTMENT AND

SPEED REGULATOR SETTING.

G) Excessive head loss in the air distribution

sistem.

1) Check the dimensioning of the air distribution

system, as well as all its parts (ducts, suspended

ceilings, oor plenum, air grilles)

2) (For TDCR and TUCR models - having fans

with backward curved blades) change the power

supply voltage of the fans, in order to increase

the fan rotation speed.

PROBLEM POSSIBLE CAUSE CHECK/CORRECTIVE ACTION

INTERVENTION OF

ONE OR BOTH OF THE

ELECTRICAL HEATERS’

SAFETY THERMOSTATS

A) There is insufcient air ow. See “LACK OF / ABSENT AIR FLOW”.

B) The thermostat connection wire is interrupted

Check the continuity of the connection of the

safety thermostats to the control system.

C) One or both of the thermostats are broken

Replace one or both of the electrical heaters’

safety thermostats

Loading...

Loading...