RLC-SVX19G-GB

101

11UNT-PRC002-GB

Sound power levels

Discharge

Measurement conditions:

Measurements taken in a room adjacent to the room containing the FWD, at the outlet of the rectangular duct (1.5 m

long) fixed to its discharge opening.

Fan Power level in dB(A), per Hz frequency band Overall power

Unit speed 125 250 500 1000 2000 4000 8000 dB(A)

1 55 50 42 37 37 31 30 46

FWD 08 2 57 54 47 40 30 38 40 50

3 58 57 50 42 32 40 43 53

1 57 51 45 42 34 33 28 48

FWD 10 2 58 54 48 45 38 39 35 51

3 60 58 50 48 40 42 39 54

1 57 51 45 42 34 33 28 48

FWD 12 2 58 54 48 45 38 39 35 51

3 60 58 50 48 40 42 39 54

1 56 62 50 48 39 38 36 56

FWD 14 2 61 66 55 53 47 46 45 60

3 63 69 58 56 50 50 49 63

1 57 63 51 49 40 39 37 57

FWD 20 2 61 66 55 53 47 46 45 60

3 63 69 58 56 50 50 49 63

Intake

Measurement conditions:

Measurements taken at the horizontal air intake.

Fan Power level in dB(A), per Hz frequency band Overall power

Unit speed 125 250 500 1000 2000 4000 8000 dB(A)

1 56 55 55 53 46 45 42 57

FWD 08 2 63 62 60 60 53 53 53 64

3 66 65 63 62 56 55 57 67

1 62 58 55 58 51 48 44 61

FWD 10 2 66 63 60 62 56 55 52 66

3 70 67 63 65 59 59 57 69

1 62 58 55 58 51 48 44 61

FWD 12 2 66 63 60 62 56 55 52 66

3 70 67 63 65 59 59 57 69

1 66 65 65 65 57 50 46 68

FWD 14 2 73 72 69 71 64 59 57 74

3 78 76 73 75 69 64 63 78

1 68 72 64 64 56 52 50 69

FWD 20 2 76 76 68 71 65 61 61 75

3 78 79 71 74 69 66 66 78

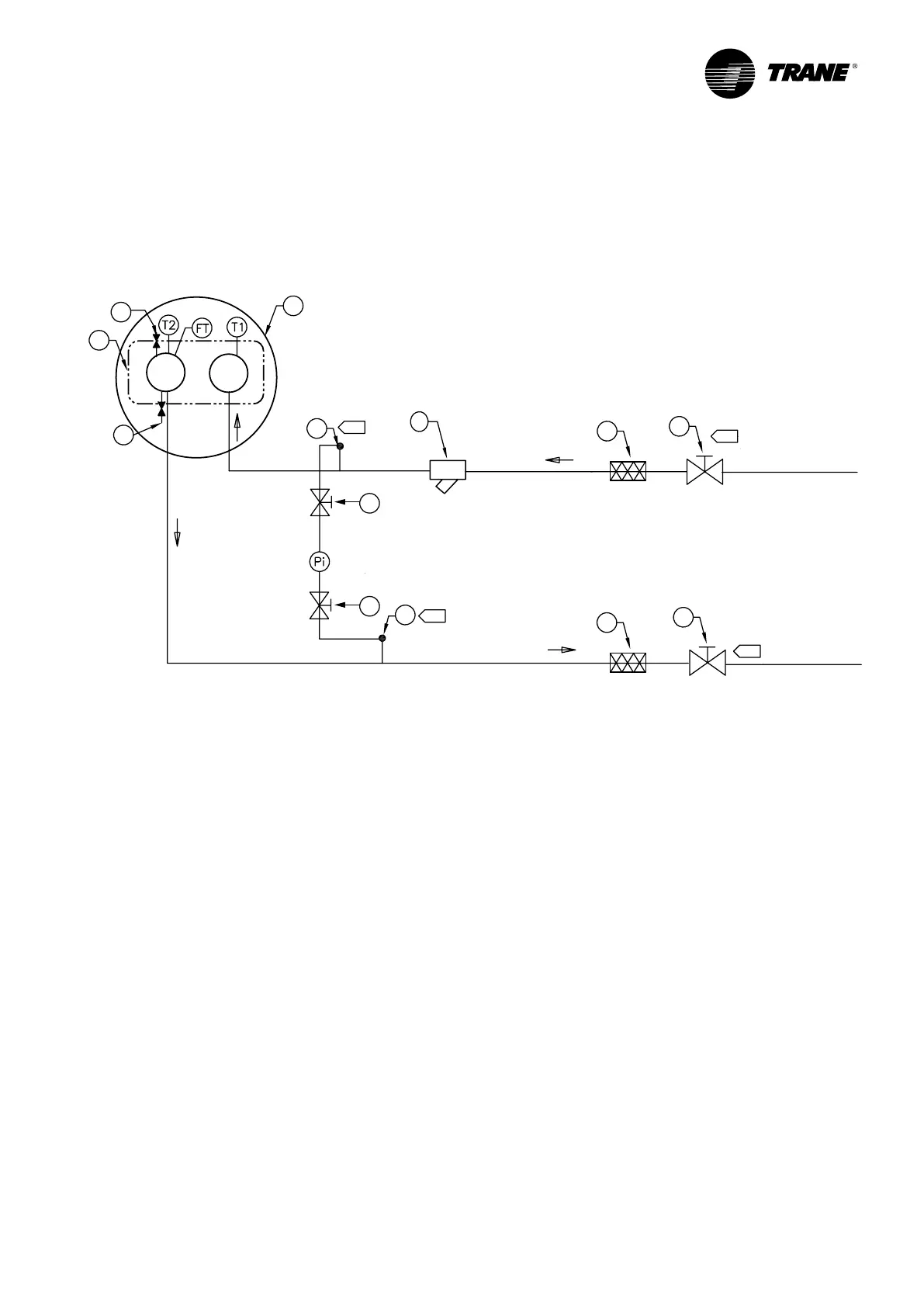

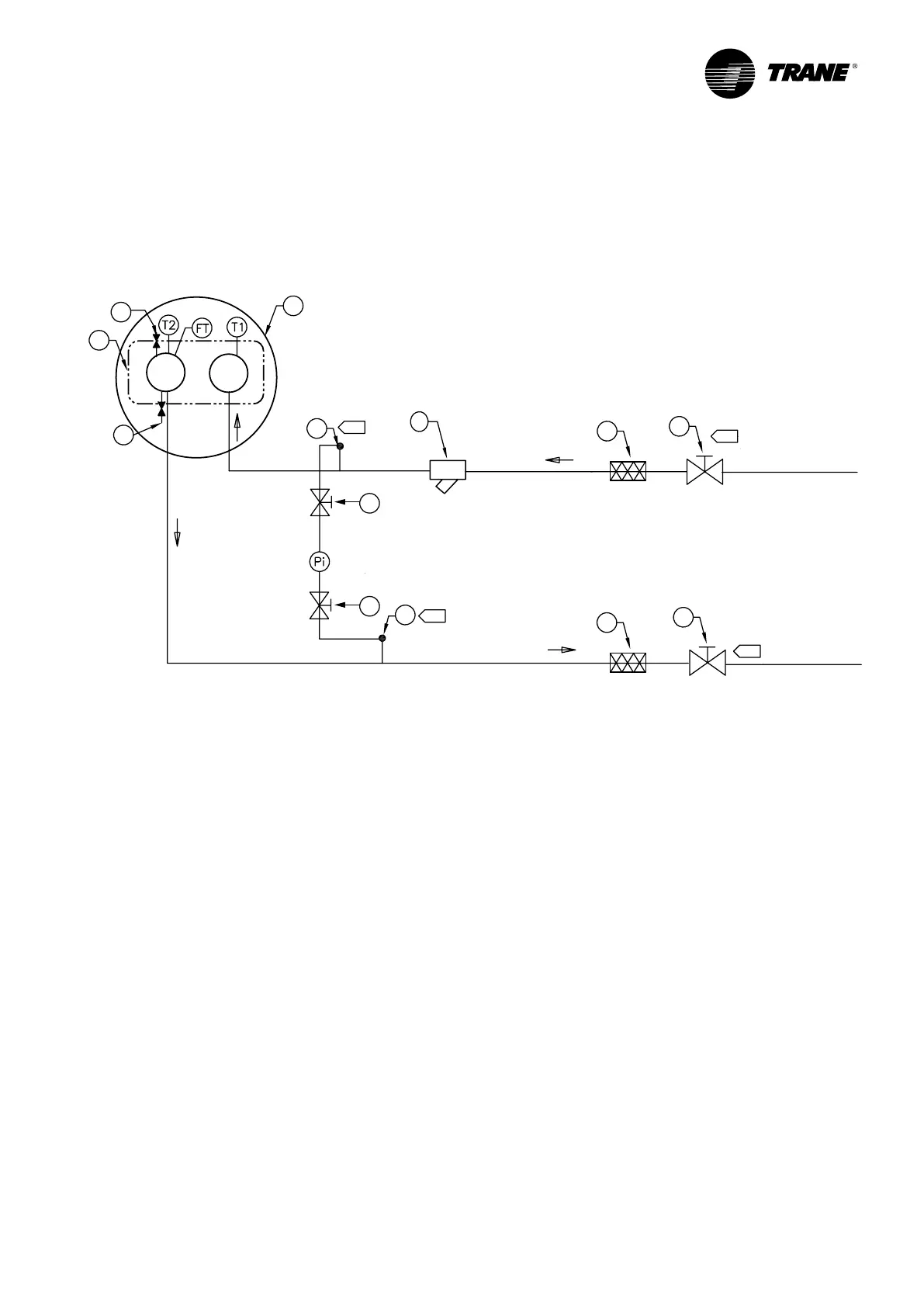

Evaporator Piping

Evaporator Piping Components

Piping components include all devices and controls used to provide proper water system operation and unit

operating safety. A typical RTAF evaporator piping is shown below.

Figure 3 – Typical RTAF evaporator water piping

1 = Isolation valve

2 = Vibration isolators

3 = Evaporator – End view (2-pass)

4 = Evaporator Waterbox

5 = Vent

6 = Strainer

7 = Drain

Entering Chilled Water Piping

• Air vents to bleed the air from the system (to be placed

on the highest point)

• Water pressure gauges with shutoff valves

• Vibration eliminators

• Shutoff (isolation) valves

• Thermometers if desired (temperature readings

available on chiller controller display)

• Clean-out tees

• Pipe strainer

Pi = Pressure gauge

FT = Water Flow Switch

T1 = Evaporator Water Inlet Temperature Sensor

T2 = Evaporator Water Outlet Temperature Sensor

A = Isolate unit for initial water loop cleaning

B = Vent must be installed at the high point of the line

C = Drain must be installed at the low point of the line

Leaving Chilled Water Piping

• Air vents to bleed the air from the system (to be placed

on the highest point)

• Water pressure gauges with shut off valves

• Vibration eliminators

• Shutoff (isolation) valves

• Thermometers (temperature readings available on the

chiller controller display)

• Clean-out tees

• Balancing valve

• Flow Proving Device

1

1

2

2

6

7

5

3

4

1

1

A

A

B

7

C

Loading...

Loading...