Installation

20 RCDA-SVN002C-EN

Programming the Tracer

®

AdaptiView™

1. Configure the UC800 using Tracer

®

TU. Refer to the

KestrelView report and write all the programming

entries in the order listed.

Note: For m

ore infor

mation regarding the use of the

Tracer TU service tool, installation, operation

and programming of the Tracer UC800

controller, operation of the control system, and

a guide to the diagnostics and troubleshooting

of the control system, please refer to the

following manuals:

• TT

U-SVN01*-EN (Getting Started Guide: Tracer

TU Service Tool)

• RTAC-SVX

01*-EN (Installation, Operation, a

nd

Maintenance, Series R Air-Cooled Helical Rotary

Liquid Chillers)

NOTICE:

Separate AC Power Required for

Computers when Working on Tracer

AdaptiView!

Failure to follow instructions below could result in

damage to the controller. When doing any service work

on a Tracer AdaptiView control system that requires

connecting a laptop computer running Tracer TU

service tool software to the UC800 controller, the

laptop must be operated from a SEPARATE AC power

source AT ALL TIMES. NEVER run the laptop on internal

battery power alone while connected to a UC800

controller! Should the computer’s internal battery die

or malfunction while connected to a UC800, fatal

corruptions could occur to the electronic files within

the controller that will render it completely inoperable

and unable to accept new programming, requiring it to

be replaced with new UC800. Damaging a UC800

controller in this manner is not covered under any

warranty!

2. Obtain a working AC power

adapter with which t

o

power the technician’s laptop.

3. Connect the computer with th

e Trac

er TU service tool

software to the service port of the Tracer UC800

controller with a USB type A/B cable.

4. Open Tracer TU.

Note: The UC800 ships with no s

oftware loaded.

When first connecting to Tracer TU, a pop-up

will direct you toward the software download

page.

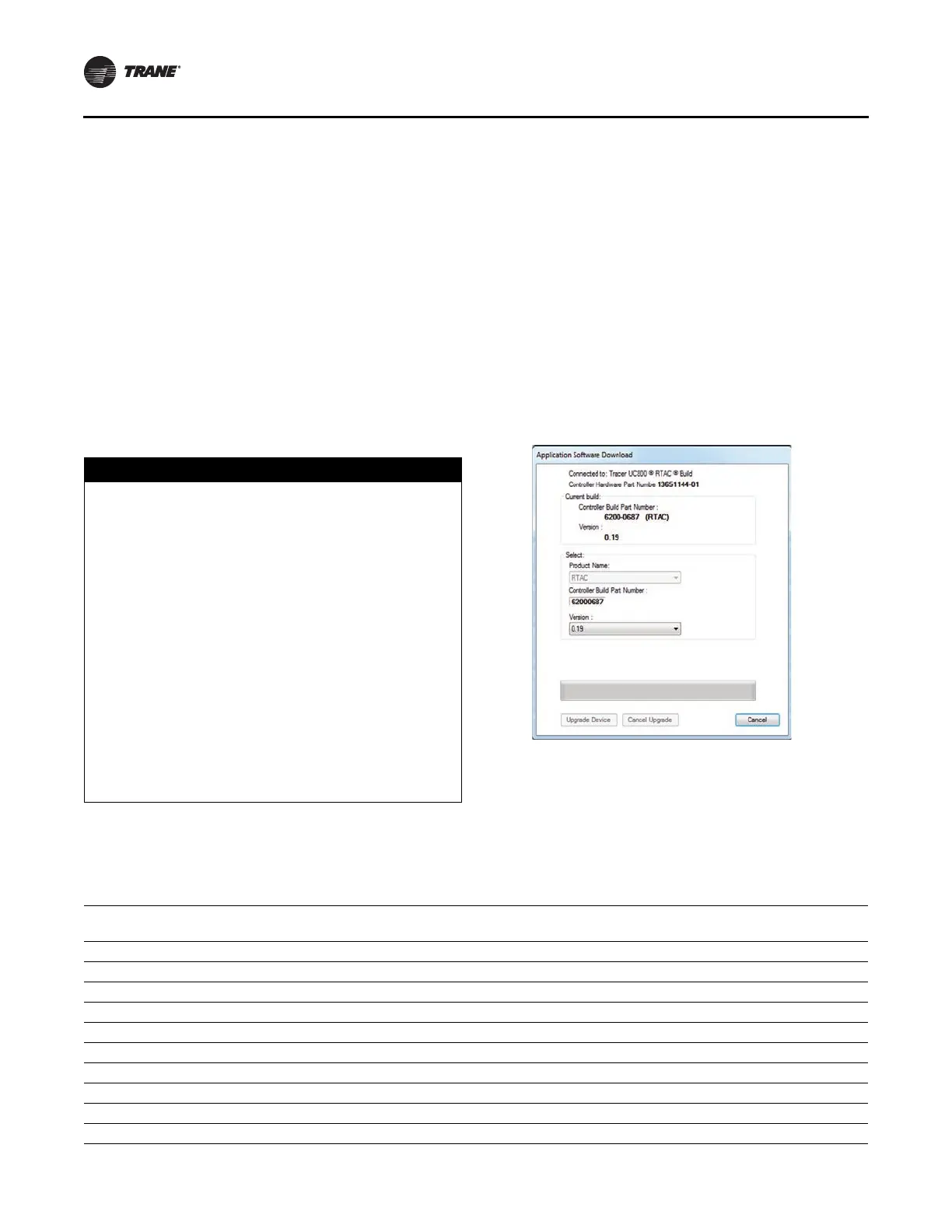

5. Select the appropriate product type (RTAC), and select

the la

test version listed.

6. Click the Upgr

ade Devic

e button when complete. See

Figure 29.

Figure 29. Application software download

7. Use the Chiller Report PDF to manually

copy the

configuration parameters in Tracer

®

TU. See Table 15

for correct mappings. After the configuration is saved,

Tracer TU will automatically proceed to LLID Binding

view. Check to see if any of the listed devices need to

be bound, indicated by a red box. See Figure 30, p. 23.

Table 15. Mapping table

Compressor

Frame Size

(a)

Manufacturing

Location

(b)

Unit Type

(Model Number Digit 12)

(c)

Unit

Voltage

(d)

Compressor

RLA

(e)

CT Meter

Scale

(f)

K1 Charmes N = Standard, A = Extra Efficiency 400 51 75

K1 Charmes H = High Efficiency 400 51 75

K2 Charmes N = Standard, A = Extra Efficiency 400 61 75

K2 Charmes H = High Efficiency 400 61 75

L1 Charmes N = Standard, A = Extra Efficiency 400 75 100

L1 Charmes H = High Efficiency 400 75 100

L2 Charmes N = Standard, A = Extra Efficiency 400 92 100

L2 Charmes H = High Efficiency 400 92 100

M1,M3 Curitiba, Pueblo, Taicang H = High Efficiency 575 90 100

M1,M3 Curitiba, Pueblo, Taicang N = Standard, A = Extra Efficiency 575 94 100

Loading...

Loading...