5.2

Safety notes on installation

Sharp edges, sharp corners and thin sheet metal

parts

CAUTION!

Danger of injury at sharp edges, sharp corners

and thin sheet metal parts!

Sharp edges, sharp corners and thin sheet metal

parts may cause cuts or grazes.

– Be careful when carrying out any work.

– Wear protective gloves, safety shoes and a hard

hat.

5.3

General installation information

NOTICE!

Damage to the fire damper

– Protect the fire damper from contamination and

damage.

– Cover openings and release mechanism (e.g.

with plastic foil) to protect them from mortar and

dripping water.

– Do not remove the transport and installation pro-

tection (if any) until installation is complete.

Please note:

Operating components, electric actuator, and

inspection access must remain accessible for

inspection and maintenance work.

Loads imposed on the casing may impair the func-

tion of the fire damper. The fire damper must hence

be installed without exercising any tension.

Mortar-based installation: The perimeter gap »s

« must be large enough such that mortar can be

filled in even in case of thicker walls.

Before installation: Perform a functional test, then

close the fire damper.

Ä

52

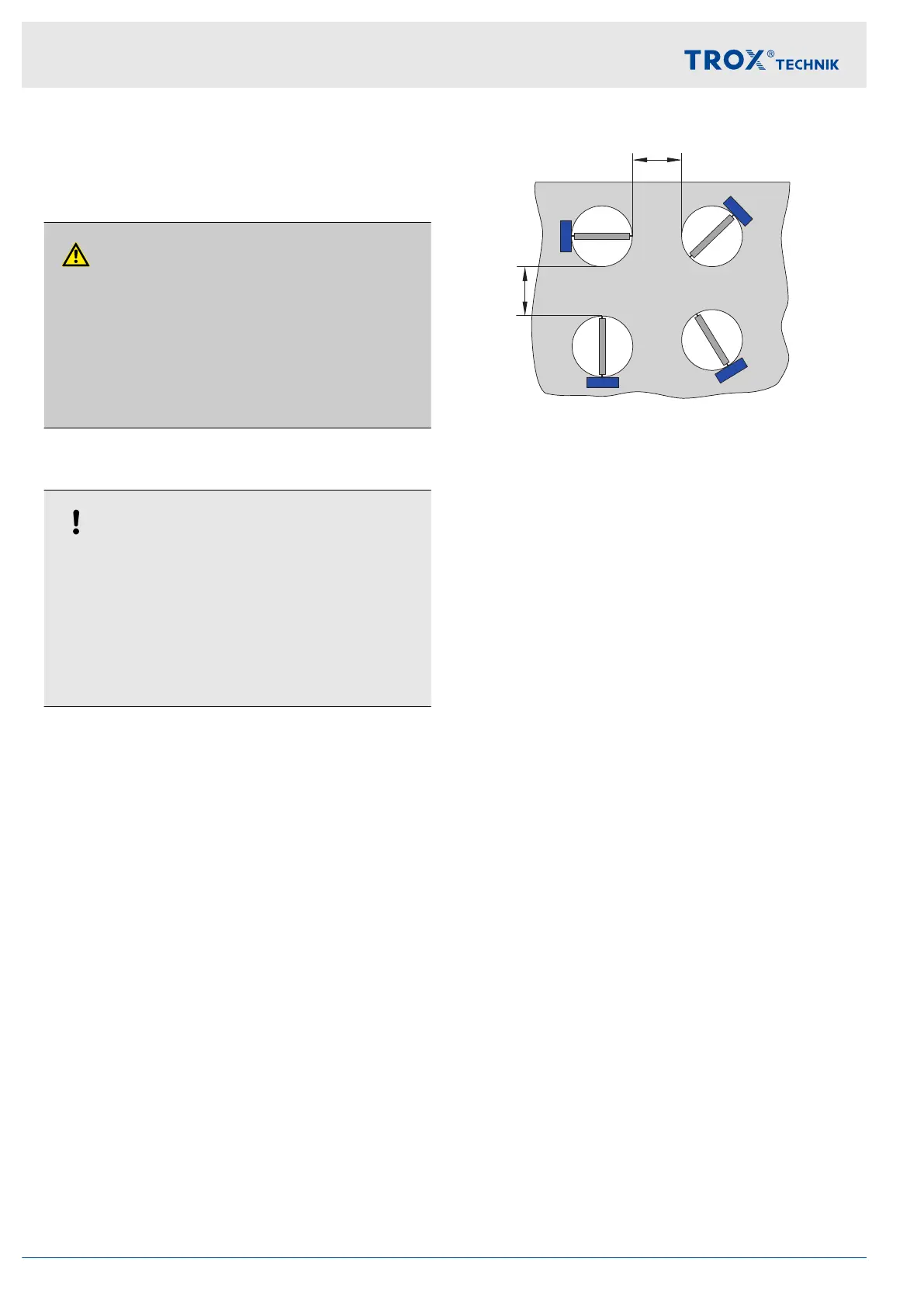

Installation position

The fire damper can be installed with the damper blade

shaft in any position (0 to 360°)(Fig. 6). The position of

the release mechanism is not critical but the mechanism

must remain accessible for maintenance.

Fig. 6: Installation positions and distances

a Distance between two fire dampers. The distance

depends on the installation situation and is given in

the installation details.

Acceptable mortars for mortar-based installation

In case of mortar-based installation, the open spaces

between the fire damper casing and the wall or ceiling

slab must be closed off with mortar. Entrapped air is to

be avoided. The mortar bed depth should be equal to

the thickness of the wall but must be at least 100 mm.

The following mortars are acceptable:

DIN 1053: Groups II, IIa, III, IIIa; fire protection

mortar of groups II, III

EN 998-2: Classes M 2.5 to M 10 or fire protection

mortar of classes M 2.5 to M 10

Equivalent mortars that meet the requirements of

the above standards, gypsum mortar or concrete

Acceptable fire batt systems

The following fire batt systems may be used:

Hilti fire batt system

Firestop board CFS-CT B 1S 140/50

Fire protection coating CFS-CT

Fire protection sealant CFS-S ACR

HENSEL fire batt system

Mineral wool slab ROCKWOOL Hardrock 40

Fire protection coating

HENSOMASTIK 5 KS Farbe (coating)

Fire protection sealant

HENSOMASTIK 5 KS Spachtel (sealant)

5.3.1

After installation

Clean the fire damper.

Remove transport and installation protection, if any.

In case of mortar-based installation this protection

must not be removed until the mortar has hardened.

Test the function of the fire damper.

Installation

General installation information > After installation

Fire damper Type FKRS-EU14

Loading...

Loading...