10

Maintenance

10.1

General

General safety notes

DANGER!

Danger of electric shock! Do not touch any live com-

ponents! Electrical equipment carries a dangerous

electrical voltage.

– Only skilled qualified electricians are allowed to

work on the electrical system.

– Switch off the power supply before working on

any electrical equipment.

CAUTION!

Danger due to inadvertently actuating the fire

damper. Inadvertent actuation of the damper blade

or other parts can lead to injuries.

Make sure that the damper blade cannot be

released inadvertently.

Regular care and maintenance ensure operational read-

iness, functional reliability, and long service life of the

fire damper.

The owner or operator of the system is responsible for

the maintenance of the fire damper. The operator is

responsible for creating a maintenance plan, for defining

the maintenance objectives, and for the functional relia-

bility of the fire damper.

Functional test

The functional reliability of the fire damper must be

tested at least every six months; this has to be arranged

by the owner or operator. If two consecutive tests, one

6 months after the other, are successful, the next test

can be conducted one year later.

The functional test must be carried out in compliance

with the basic maintenance principles of the following

standards:

EN 13306

DIN 31051

EN 15423

The function of fire dampers with a spring return

actuator can also be tested with an automatic control

unit

Ä

‘Functional test with automatic control unit’

on page 54.

Maintenance

The fire damper and the spring return actuator are

maintenance-free with regard to wear but fire dampers

must still be included in the regular cleaning of the venti-

lation system.

Cleaning

The fire damper may be cleaned with a dry or damp

cloth. Sticky dirt or contamination may be removed with

a commercial, non-aggressive cleaning agent. Do not

use abrasive cleaners or tools (e.g. brushes).

Inspection

The fire damper must be inspected before commis-

sioning. After commissioning, the function has to be

tested in regular intervals. Local requirements and

building regulations must be complied with. The inspec-

tion measures to be taken are listed under

Ä

on page 59. The test of each fire damper must be

documented and evaluated. If the requirements are not

fully met, suitable remedial action must be taken.

Repair

For safety reasons, repair work must only be carried out

by expert qualified personnel or the manufacturer. Only

original replacement parts are to be used. A functional

test

Ä

52 is required after any repair work.

10.2

Lubricating points

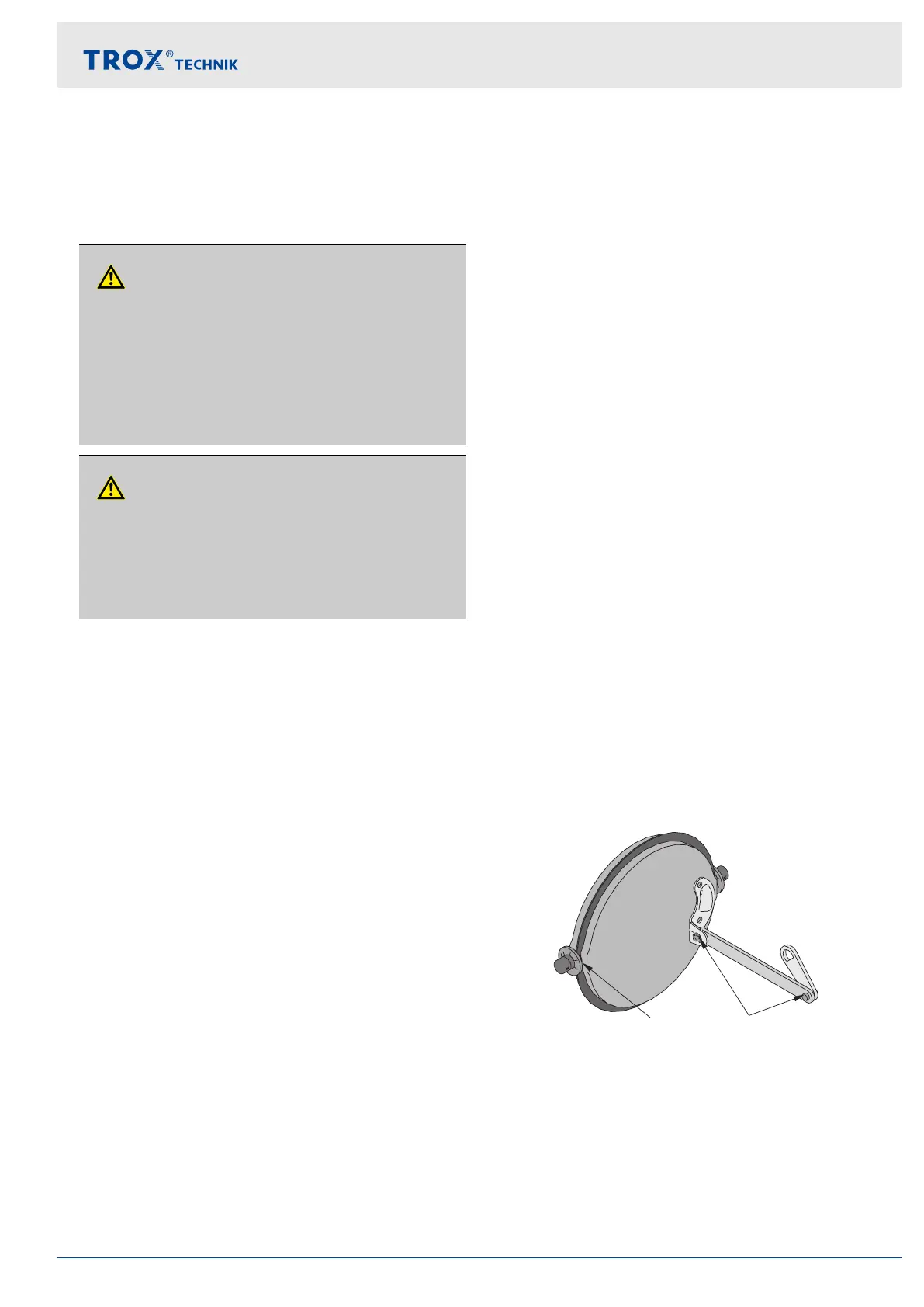

Lubricating points

Fig. 48: Lubricating points

①

Push rod bearings

②

Damper blade bearings (both sides)

Only lubricate the lubricating points if the damper blade

cannot be opened or closed easily. Use only oil or

grease that is free of resins or acids.

Maintenance

Lubricating points

Fire damper Type FKRS-EU 57

Loading...

Loading...