Unifiller Systems Inc. Page 14 of 48 Manual Part No.: MINI

DOPOSITOR

Inspection and Reassembly

1. Place auger into hopper prior to reassembly.

2. Reattach hopper to frame by aligning and latching the 2 toggle clamps

3. Align and re-attach the auger shaft to the motor shaft and slide coupling into place.

4. Place die into proper position prior to attaching safety guard to hopper. Slide Safety guard with

cutting mechanism attached back into alignment with the hopper outfeed.

5. Replace and secure the triclamp around the hopper outfeed.

Note:

If you need assistance on troubleshooting your machine, please copy and fill out the Unifiller

Diagnostic Record Log at the end of this manual before contacting Unifiller whenever possible.

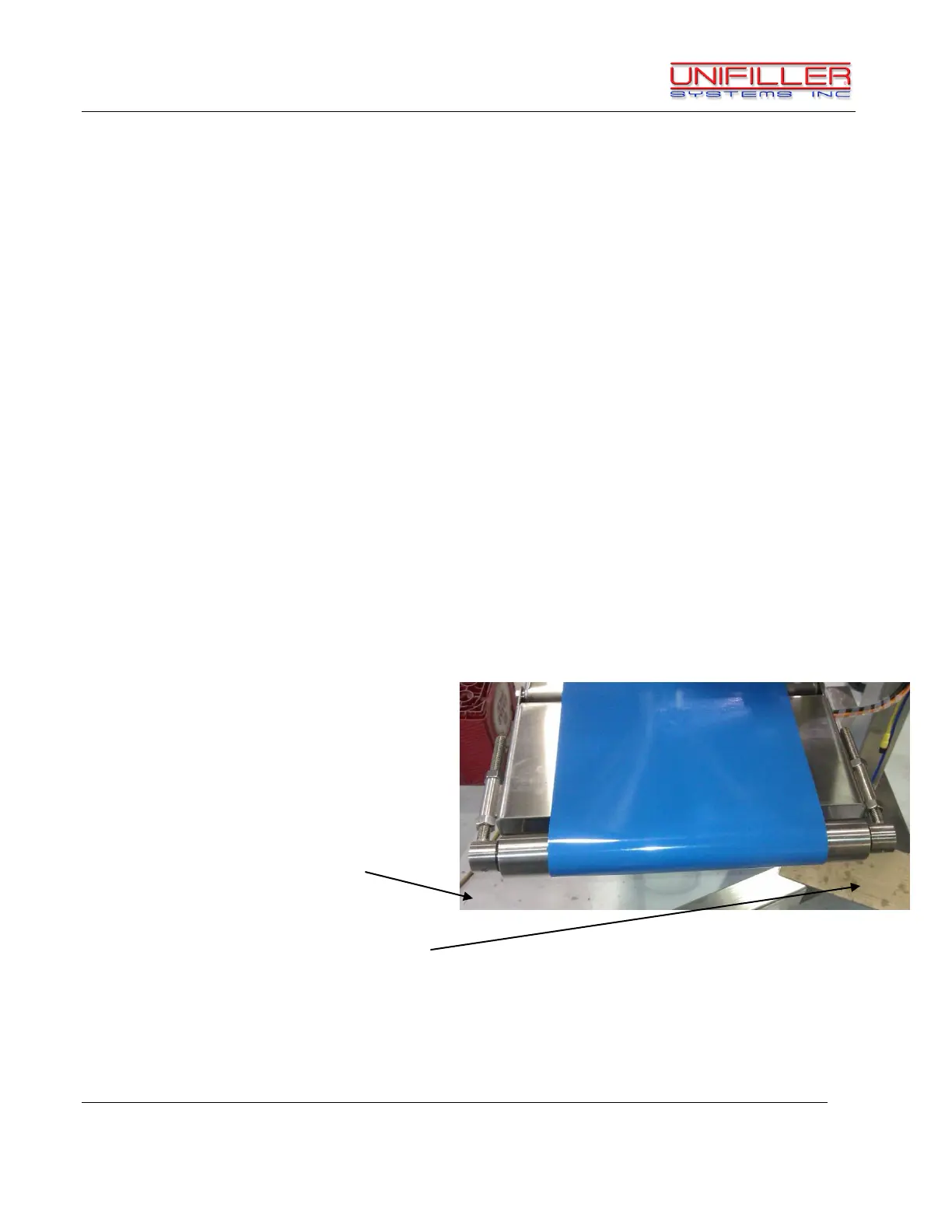

Conveyor Belt Tracking and

Tightening

The Conveyor belt is designed to run in the

center of the conveyor bed.

If the belt moves excessively to one side, turn

the nut to tighten the “high” side to steer the

belt back to center.

If the conveyor belt is slipping, tighten both nuts to increase the tension of the conveyor belt.

CAUTION:

Do not tension belt excessively as it will cause premature failure of the motorized pulley and idler

pulley.

Always ensure there is no moisture between the belt and conveyor bed as this will produce a wet

bond of the belt to the bed. This will prevent movement of the belt and lead to premature wearing.

Proper and safe belt tension is achieved when the belt slips on the drive pulley when the belt is

pressed firmly onto the conveyor bed.

Loading...

Loading...