Unifiller Systems Inc. Page 37 of 48 Manual Part No.: MINI

DOPOSITOR

Alarms and Diagnostics

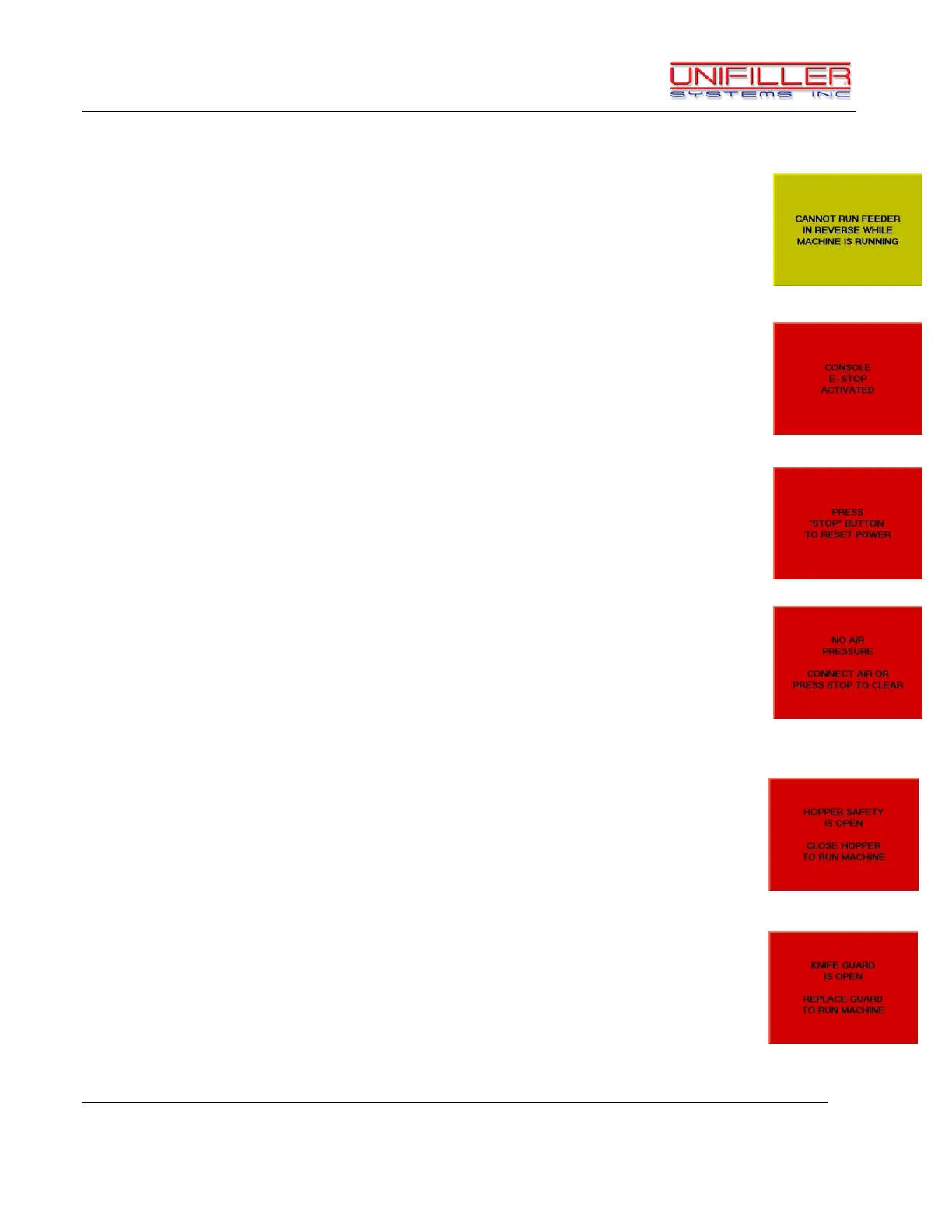

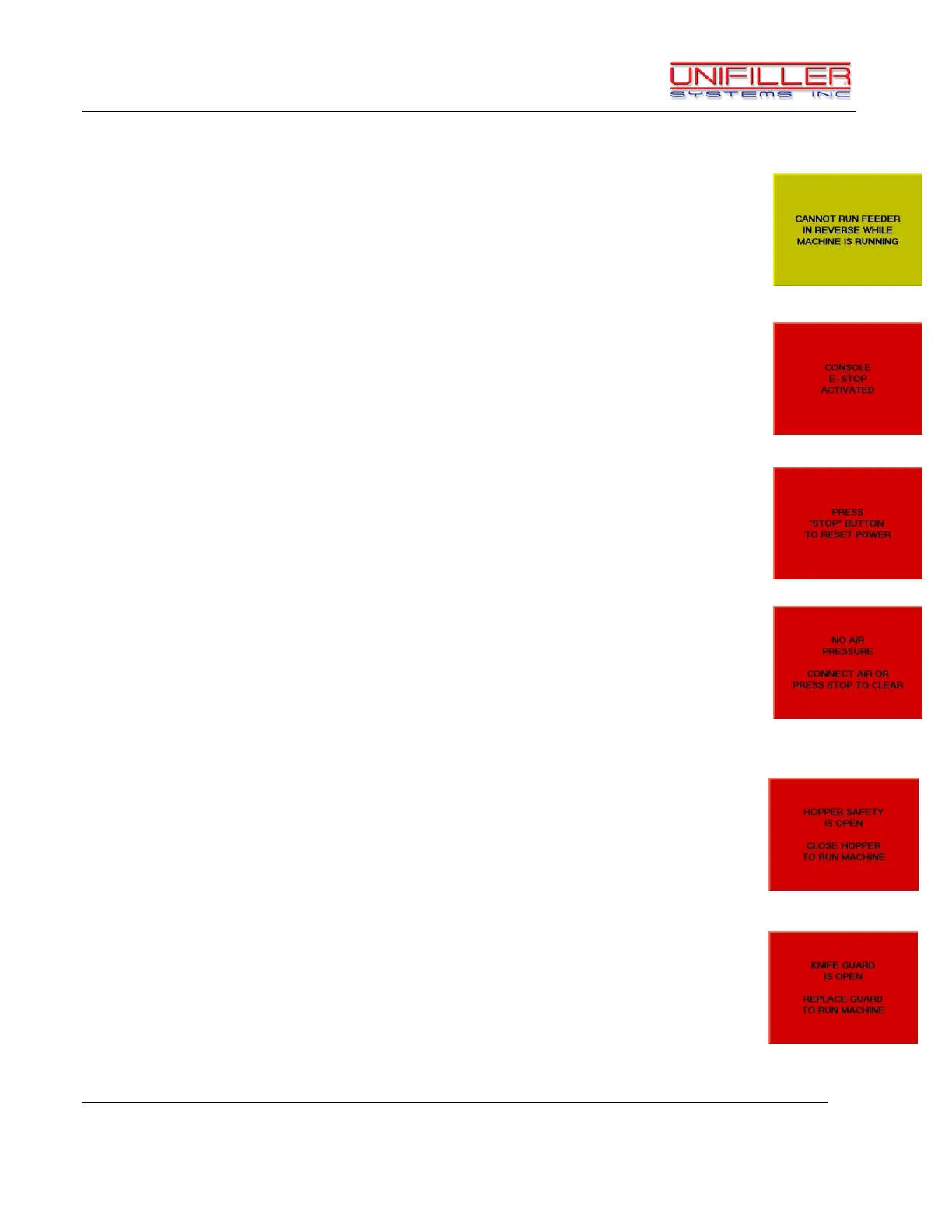

Feeder Reverse - Warning

The “Roller Reverse” pushbutton was pressed while the machine was

running or while the auger was running forward.

Release the pushbutton and stop the rollers to run in reverse.

Console E-Stop

The console E-Stop button is pressed in, pull it out and follow the

directions on screen.

Press Stop to Reset

Check all conveyor E-Stops to make sure they are reset.

Press Stop to reset the machine.

No Air

The Main Air sensor is not sensing air pressure;

Check air connections to the Dopositor and shut-off valves.

Check that the air pressure is 80 PSI.

If all else has failed, the Main Air sensor may need to be replaced; in the

mean time, shut off the air sensor on the

Technical 2 screen to get back into production.

Hopper Safety

The hopper is open; close the hopper and make sure it is seated right

down to operate the machine.

Check that the sensor is close enough to the magnet and that the magnet

and sensor are aligned properly.

Replace the sensor if it has failed.

Knife Guard

The knife guard has been removed; replace the knife guard and make

sure it is screwed right down to operate the machine.

Check that the sensor is close enough to the magnet and that the magnet

and sensor are aligned properly.

Replace the sensor if it has failed.

Loading...

Loading...