pg. 19 UNINET DTF 1000

CLEANING & MAINTENANCE

Following these simple steps daily will ensure that your printer lasts longer and help you achieve

optimal performance with little to any down time from your

UNINET™ 1000 printer.

Daily to Do

Before running anything on your printer, shake the white ink bottle well. White ink contains

titanium sediment that needs to be agitated daily to ensure there is no separation and

collection at the bottom that could result in clogs.

Every day you should to run a head cleaning regardless if you are printing that day or not. This

ensures that there are no clogged lines, the dampers are full and that the print head is

working correctly. There are two ways to initiate a head cleaning:

1. Press and hold the ink button for 7 seconds until the print head carriage begins to move.

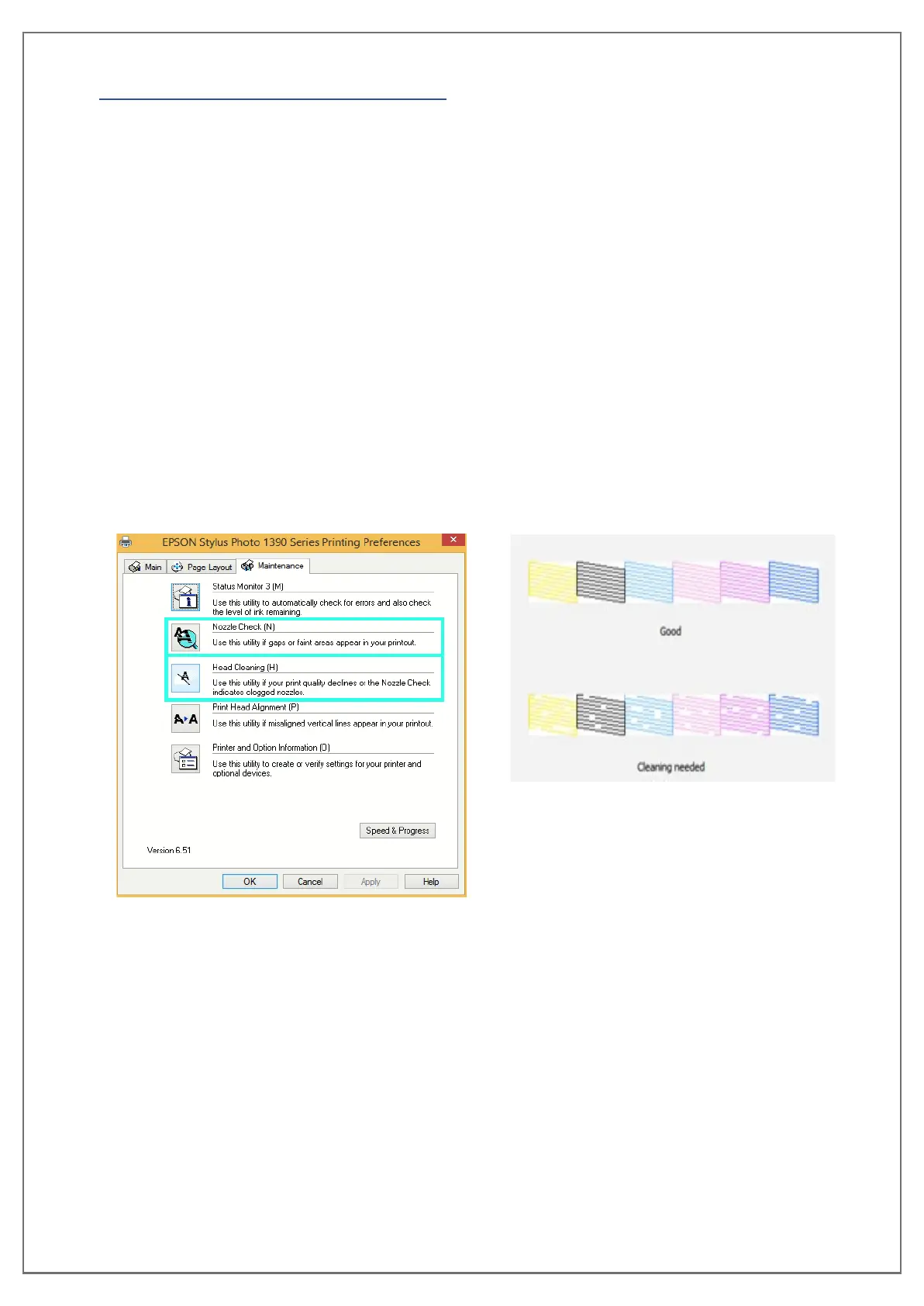

2. Go to your PC settings and search “Printers and Scanners”, select your printer and press

“Manage”. From there select “Printing Preferences”, navigate to the Maintenance tab

and select “Head Cleaning.”

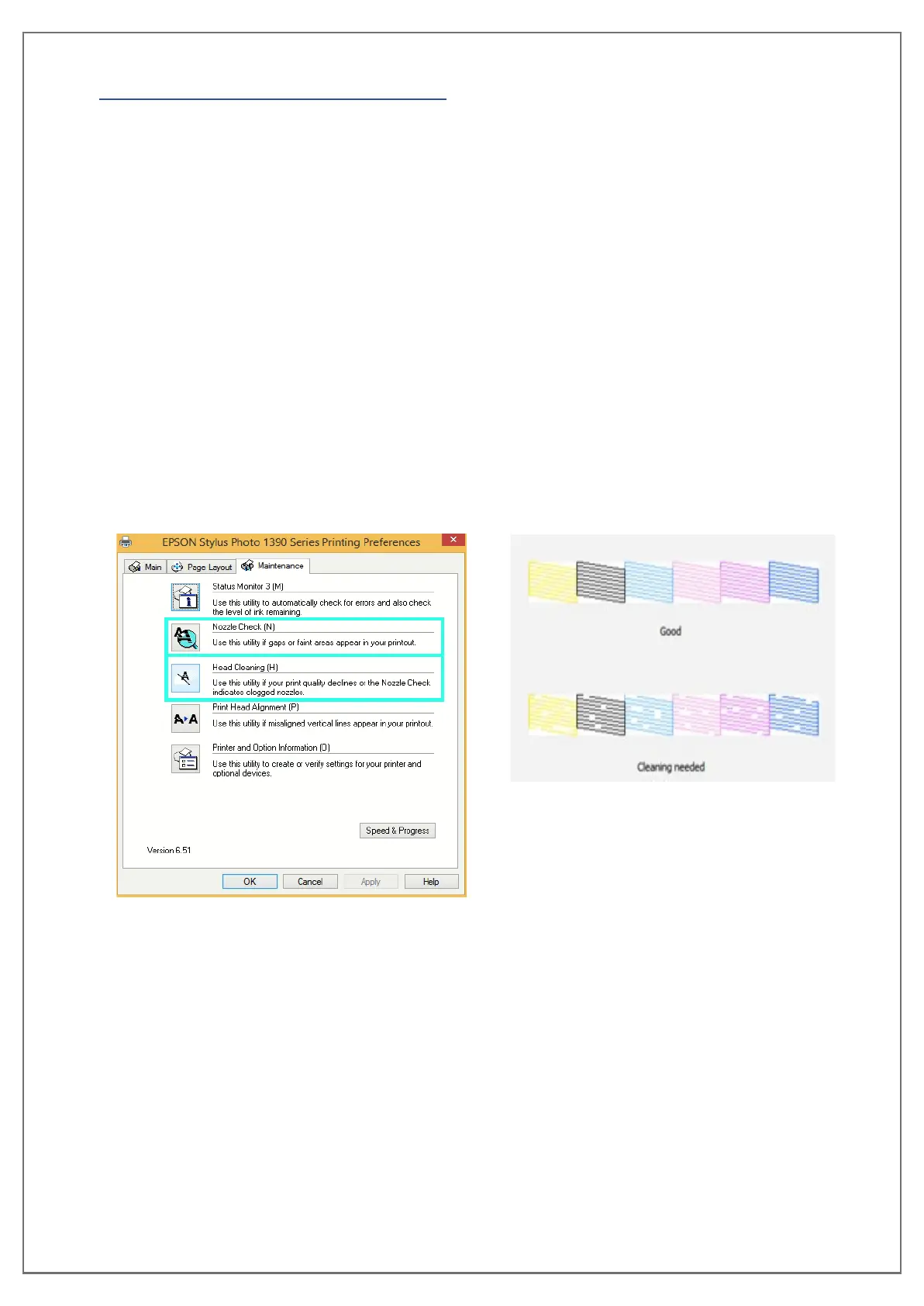

Nozzle Check Example

Once the head cleaning is complete, run a nozzle check to ensure that there are no blockages

in any of the ink channels. You can initiate a Nozzle Check from the same window you used to

start the head cleaning. If there are two or more breaks in any of the CMYK channels of the

Nozzle Check, run another head cleaning followed by another check, repeat steps if there are

still more than two breaks in any CMYK channel.

Check to verify that both the black and white WIMS switches are set to ON, they should always

be on so that the white ink lines agitate on the built in timer.

Loading...

Loading...