Section

3-14 AB46 Work Platform

Maintenance

3.12

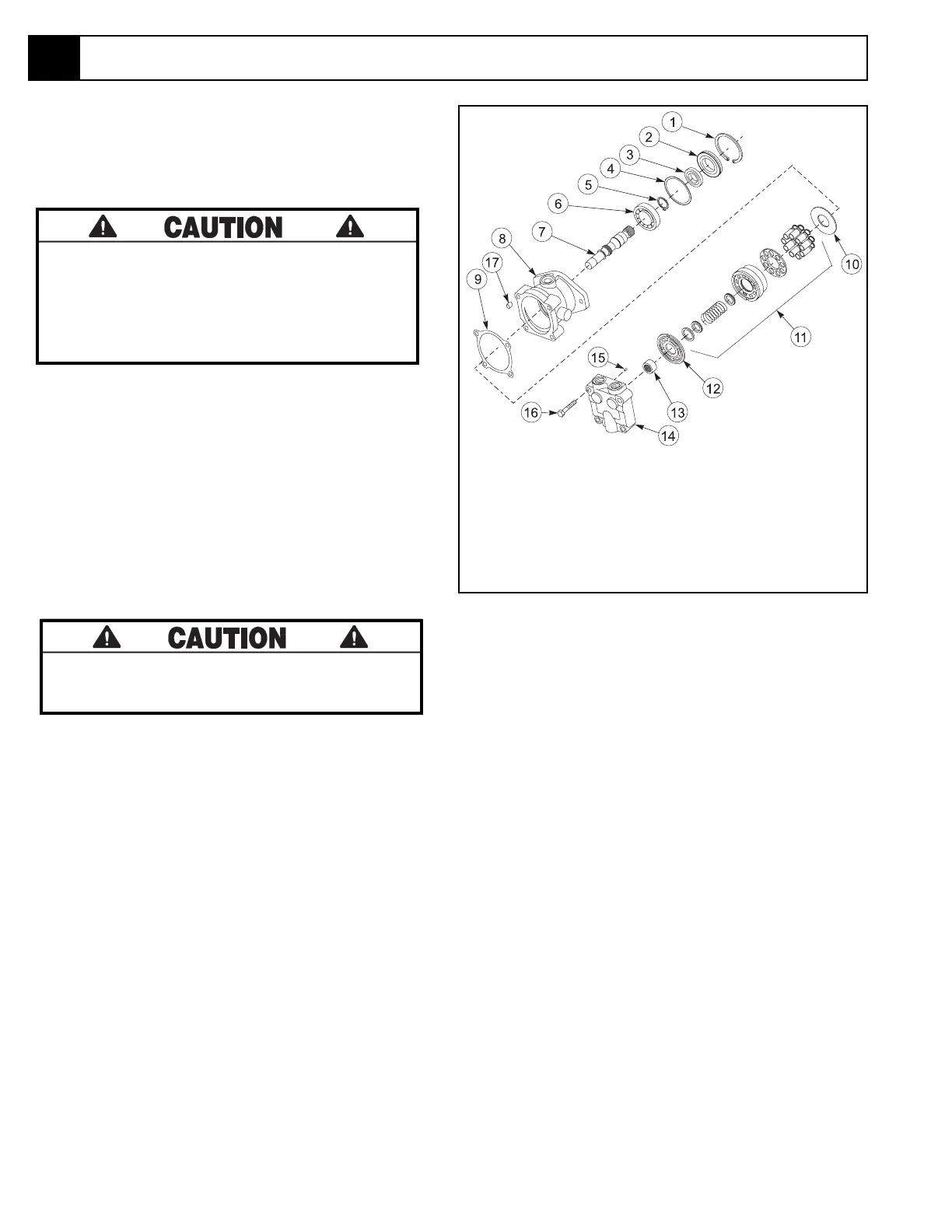

Figure 3-15: Drive Motor

8. Remove the retaining ring. Remove the shaft and

seal carrier with the seal.

9. Remove the O-ring from the seal carrier and re-

move the seal.

10. Remove small retaining ring and press the bearing

off the shaft.

Closely examine all parts for pitting and wear. If pistons

or cylinders are worn or pitted, replace cylinder block

assembly.

If needle bearing is to be replaced, remove needle

bearing using a puller. Press new bearing in place.

Bearing cage will protrude from end cap and serve as a

pilot for the valve plate.

Replace all Gaskets and O-rings. Lubricate O-rings using

petrolium jelly.

1. Retaining Ring

2. Seal Carrier

3. Lip Seal

4. O-Ring

5. Retaining Ring

6. Bearing

7. Shaft

8. Body

9. Gasket

10. Thrust Plate

11. Cylinder Kit

12. Valve Plate

13. Needle Bearing

14. End Cap

15. Pin

16. Cap Screw

17. Alignment

Sleeve

3.12 DRIVE MOTOR REMOVAL

1. Park the work platform on firm level ground.

2. Mark and remove the drive motor hydraulic lines.

Clean all fittings before disconnecting the

hose assemblies.

Plug all port holes and hose assemblies

IMMEDIATELY to prevent contamination

from dust and debris.

3. Remove the cap screws and washers which secure

the drive motor to the torque hubs. Remove the

drive motor.

Drive Motor Seal Replacement

NOTE: Refer to IPB section page 6-16 or 6-17 for

available repair parts.

DISASSEMBLY (Figure 3-15)

CAUTION: Safety glasses should be used

during disassembly of hub.

1. Remove four cap screws which secure end cap.

Remove end cap with valve plate. Do not allow

valve plate to fall off end cap.

2. Carefully remove valve plate. It may be necessary to

pry valve plate off with small screwdriver.

3. Remove the gasket.

4. Remove the alignment sleeves from housing.

5. Lay the motor on its side and remove cylinder block

assembly.

6. Remove slipper guide and piston assemblies from

cylinder block.

7. Using an O-ring pick, remove the thrust plate.

Loading...

Loading...