Maintenance

2-13

2.9 M

AINTENANCE

WARNING

!

!

Never perform service while the platform is elevated without first blocking the elevating

assembly.

DO NOT stand in the elevating assembly area while deploying or storing the brace.

B

LOCKING

T

HE

E

LEVATING

A

SSEMBLY

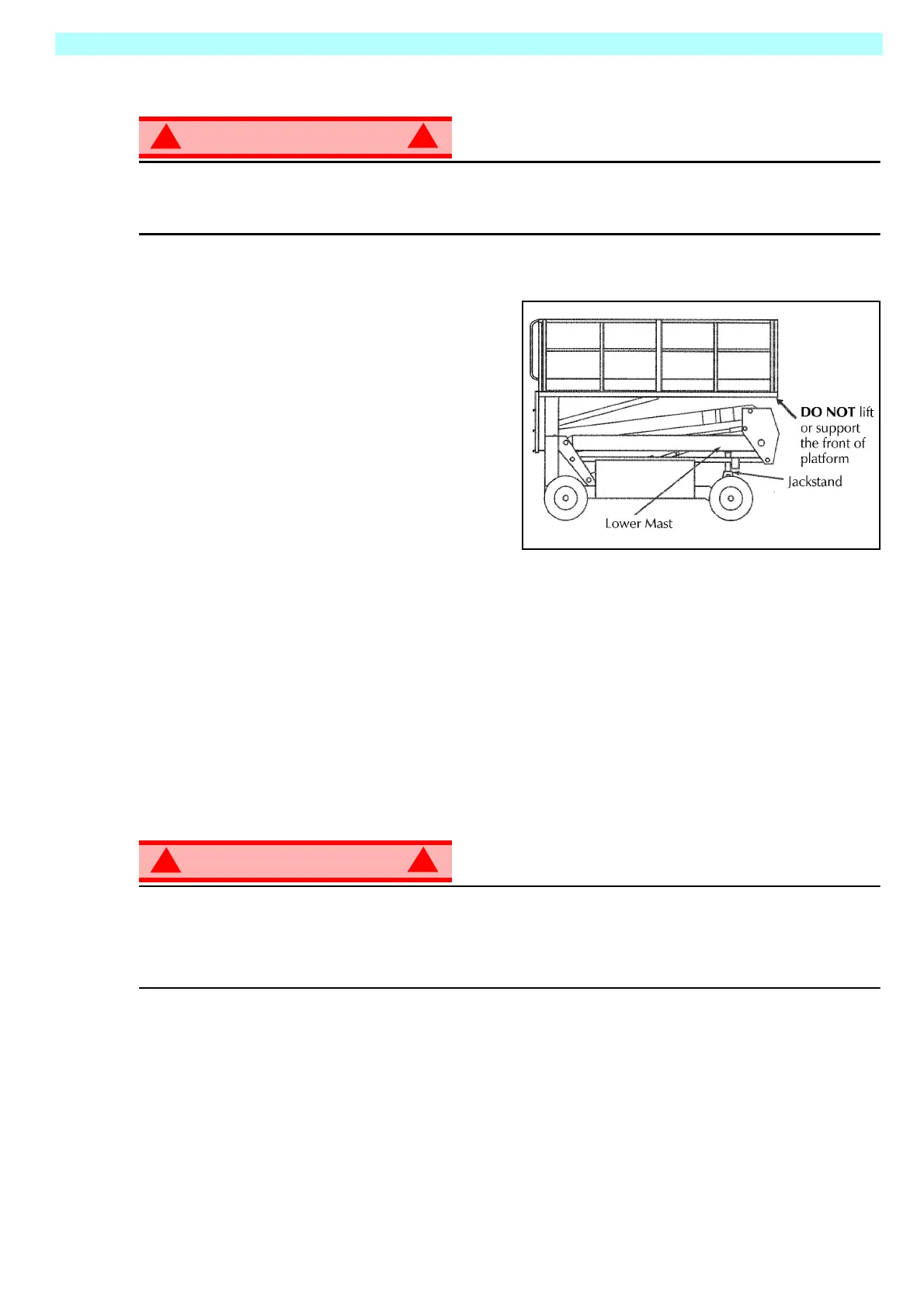

Figure 8: Scissor Brace

I

NSTALLATION

1. Park the work platform on firm, level ground

and leave the engine running.

2. Ensure the Chassis Emergency Stop Button

is twisted to the ON position.

3. Press and hold the Chassis LIFT and

ENABLE buttons to elevate the platform

approximately 305 mm (12 inches).

4. Place a jackstand with a minimum rating of

1814 kg (4000 lbs.) between the lower mast

and chassis, just behind the front axle.

5. Press and hold the Chassis DESCEND and ENABLE buttons to lower the platform until

jackstand is secured tightly between lower mast and Chassis.

R

EMOVAL

1. Press and hold the Chassis LIFT and ENABLE buttons to elevate the platform until the jack-

stand can be removed.

2. Remove jackstand.

3. Press and hold the Chassis DESCEND and ENABLE buttons to completely lower the

platform.

B

ATTERY

M

AINTENANCE

WARNING

!

!

Hazard of explosive gas mixture. Keep sparks, flame, and smoking material away from batteries.

Always wear safety glasses when working near batteries.

Battery fluid is highly corrosive. Thoroughly rinse away any spilled fluid with clean water.

Always replace batteries with UpRight batteries or manufacturer approved replacements.

• Check the battery fluid level daily, especially if the work platform is being used in a warm, dry

climate.

• If electrolyte level is lower than 10 mm

(

3

/

8

in.) above the plates add distilled water only. DO

NOT use tap water with high mineral content, as it will shorten battery life.

• Keep the terminals and tops of the batteries clean.

• Refer to the Service Manual to extend battery life and for complete service instructions.

B

ATTERY

C

HARGING

The battery is charged while the engine is running.

Loading...

Loading...