Start-up

46 Installation and maintenance instructions ecoTEC plus 0020116700_01

10

1

2

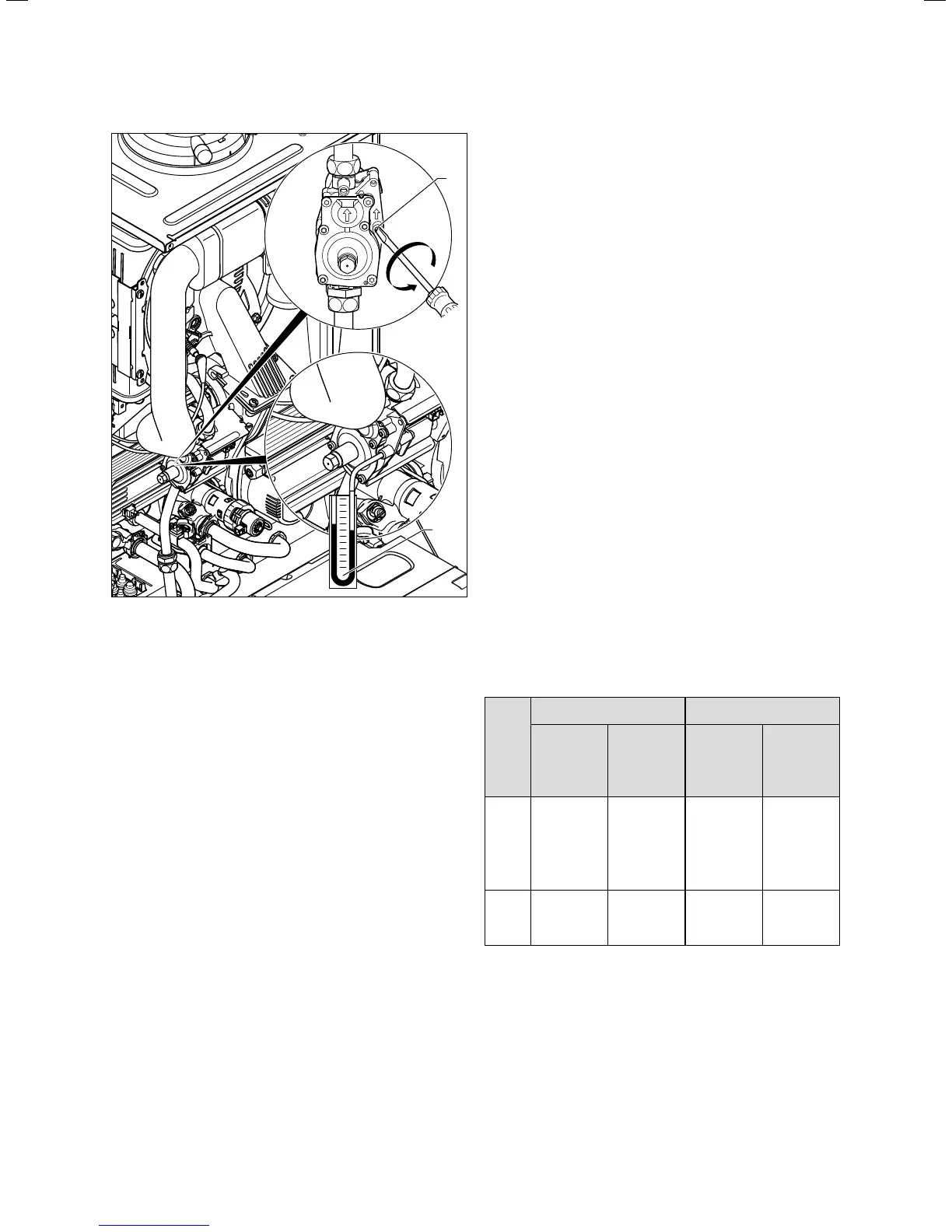

10.7 Measuring the gas inlet working pressure

> Undo the sealing screw of the measuring nipple (1)

(lower screw) at the gas valve using a screwdriver.

> Connect a digital pressure gauge or U-tube manometer

(2) to the measuring nipple (1).

> Open the gas isolation valve of the boiler.

> Start the boiler by activating the test program P.01 as

described in ¬section13.4.

> In addition, ensure that maximum heat can be dissipated

into the heating system by turning up the room thermo-

stat.

> Alternatively, for VUW-boilers: fully open the hot water

taps to ensure full flow rate through the boiler.

> With the boiler operating at full load check that the gas

inlet working pressure at the reference test point (1)

complies with the requirements of ¬table 10.3.

> Should the pressure recorded at the reference test point

in the boiler be lower than indicated (¬table 10.3) check

if there is any blockage in the pipework or if the pipe-

work is undersized.

If the supply pressure is out of tolerance contact your

Emergency Service Provider.

If the gas inlet working pressure at the reference test point

(1) is not within the permissible range and you cannot cor-

rect the failure, notify the gas supply company or the Vail-

lant Service Solutions (0870 6060 777) and proceed as fol-

lows:

> Take the boiler out of operation by

– terminating test program P.01 as described in

¬section10.4.

– Only for VUW-boilers: Allow the boiler to cool down by

turning off water taps and allow pump overrun to

operate for a minimum of two minutes.

> Close the gas isolation valve of the boiler.

> Remove the pressure gauge and retighten the sealing

screw (1) for the measuring nipple.

> Turn on gas at the gas isolation valve.

> Make sure that there is no leakage at the sealing screw.

> Turn off gas at the gas isolation valve.

> Put the front casing back on.

> Turn off electrical supply to the boiler.

> You must not start up the boiler.

If the gas inlet working pressure is within the permissible

range, proceed as follows:

> T

ake the boiler out of operation by

– terminating test program P.01 as described in

¬section10.4.

– Only for VUW-boilers: Allow the boiler to cool down by

turning off water taps and allow pump overrun to

operate for a minimum of two minutes.

> Close the gas isolation valve of the boiler.

> Remove the pressure gauge and retighten the sealing

screw (1) for the measuring nipple.

> Open the gas isolation valve of the boiler.

> Make sure that there is no leakage at the sealing screw.

> Put the front casing back on.

> Reset boiler controls for normal operation.

> Record the boiler gas inlet working pressure (kPa

resp.mbar) in the Benchmark gas boiler commissioning

checklist.

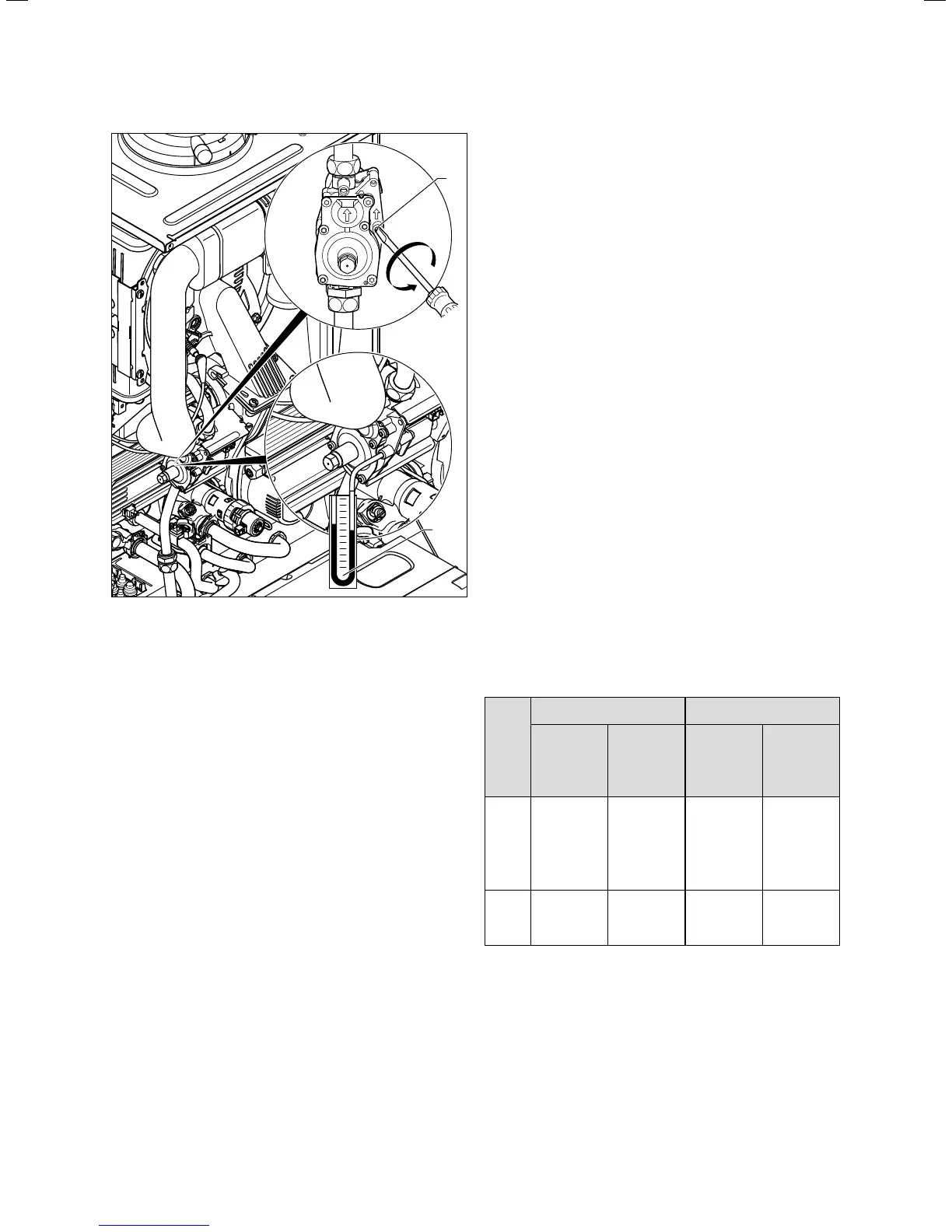

Boiler

Natural gas (G20) LPG (G31)

Minimum

pressure at

reference

test point in

kPa (mbar)

Maximum

pressure at

reference

test point in

kPa (mbar)

Minimum

pressure at

reference

test point in

kPa (mbar)

Maximum

pressure at

reference

test point in

kPa (mbar)

612/

615/

618/

624/

630/

824/

831

1,6 (16) 2,3 (23) 2,3 (23) 4,3 (43)

637/

837

1,5 (15) 2,3 (23) 2,3 (23) 4,3 (43)

10.3 Gas inlet working pressure at the reference test point

10.12 Carrying out a full function test

> After completing the installation and the gas setting, per-

form a complete function check of the boiler before start-

ing up the boiler and handing it over to the operator.

Loading...

Loading...