13 | Page

Version 00

© Verder Liquids B.V

Ds500, Ds500+ Operating manual

Original instructions (en)

7. Layout and Function

TheVerderexDs500isanindustrialperistaltic,self-priming

pumpdesignedformetering,dosingandtransfer(uid/

chemical) with a focus on accuracy and minimum downtime,

at pressures of up to 7 bar(g).

7.1 Design Details

The medium to be pumped is contained within the tube

and additional pipework and is totally contained within

the cartridge. A rotor shoe passes along the length of

the enclosed tube, compressing it. This motion forces

the contents of the tube directly in front of the shoe to

move forward along the length of the tube in a ‘positive

displacement’ peristaltic movement. In the wake of the

shoe’s compressing action, the natural elasticity of the

tube material causes the tube to recover and regain its

roundprole.Thiscreatessuctionpressurewhichrells

the tube.

7.2 Labelling

Figure 3. - Rear label

Item Description

1 Productdesignation&certication

2 Serial number / year of manufacture

Table 9. - Rear label details

When requesting spares or assistance the model and serial

numbershouldalwaysbequoted.

1 2

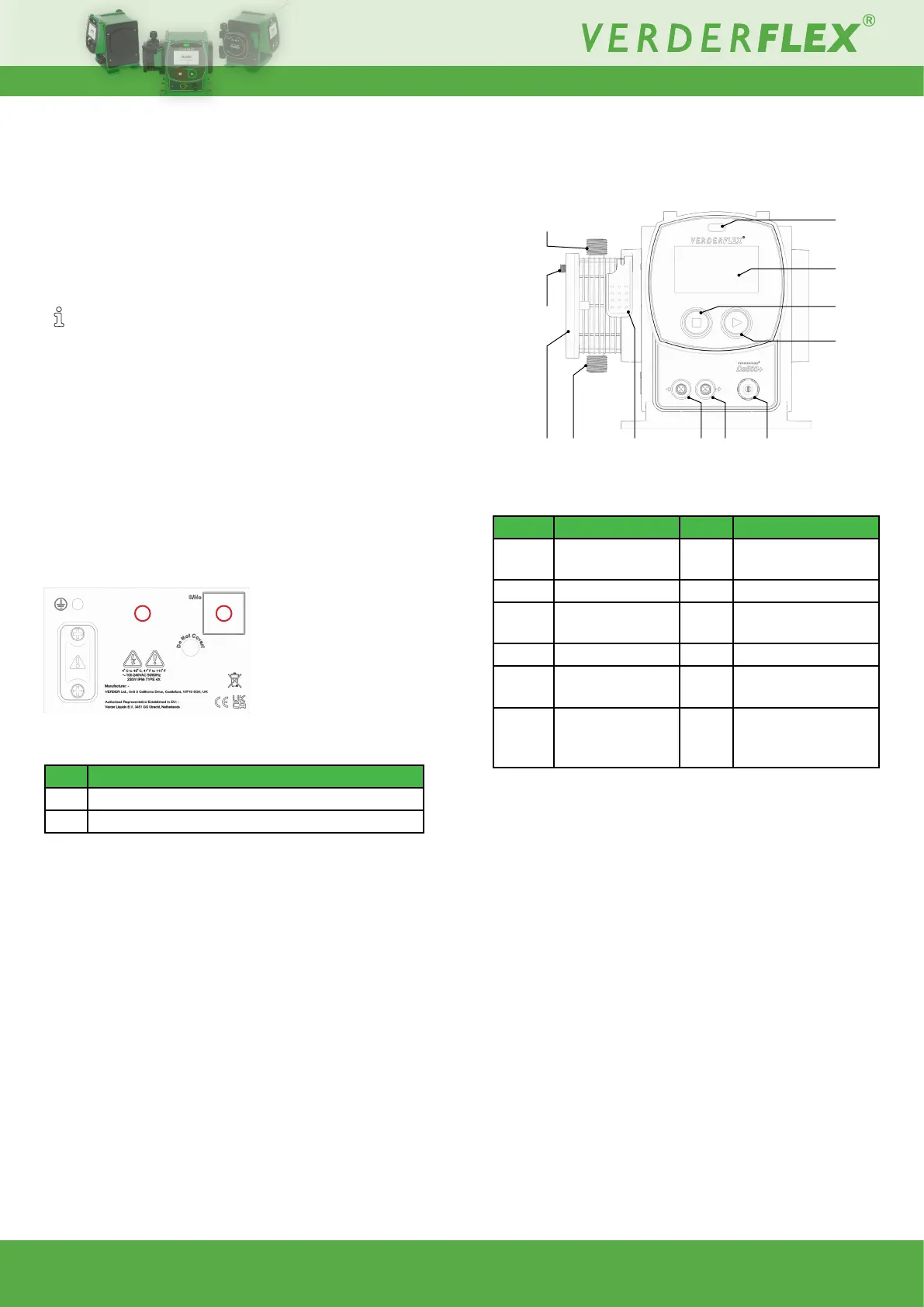

7.3 Layout

7.3.1 Front

Figure 4. - Ds500+ front

(screen protector removed)

Table 10. -

Item Description Item Description

1

LED status

indicator

2

HMI

(HumanMachineInterface)

3 Stop (red) 4 Start (green)

5

Discharge point

(out)

6 Breather point

7 Cartridge 8 Suction point (in)

9 Cartridge lock 10

Externalcontrolinput

(Ds500+ only)

11

Externalcontrol

output

(Ds500+ only)

12

Mains input (pre-

tted)

Layout (front)

LED status indicator

– Red = Stopped

Redashing=Error/fault

– Green = Running with no errors

Green ashing = Pump running with Fluid Level Monitor

warning threshold reached.

– Purpleashing=Runningwithactiveerror/fault

– Whiteashing=Firmwareupdateinprogress

HMI

– Presents information to the user about the status of the

pump.

– Allowstheoperatortomakeselectionsandadjustments.

– Can be operated by touch or suitable stylus.

Stop

1

2

3

4

5

6

7 8 9 10

11

12

Loading...

Loading...