3.3 Air-distribution Considerations for Upflow Units

For in-room applications with supply and return grilles, several feet of clearance must be maintained at

the intake and discharge of the unit.

NOTE: Drain traps are qualified to a return duct static of negative 1.5 i.w.g. (-1.5i.w.g).

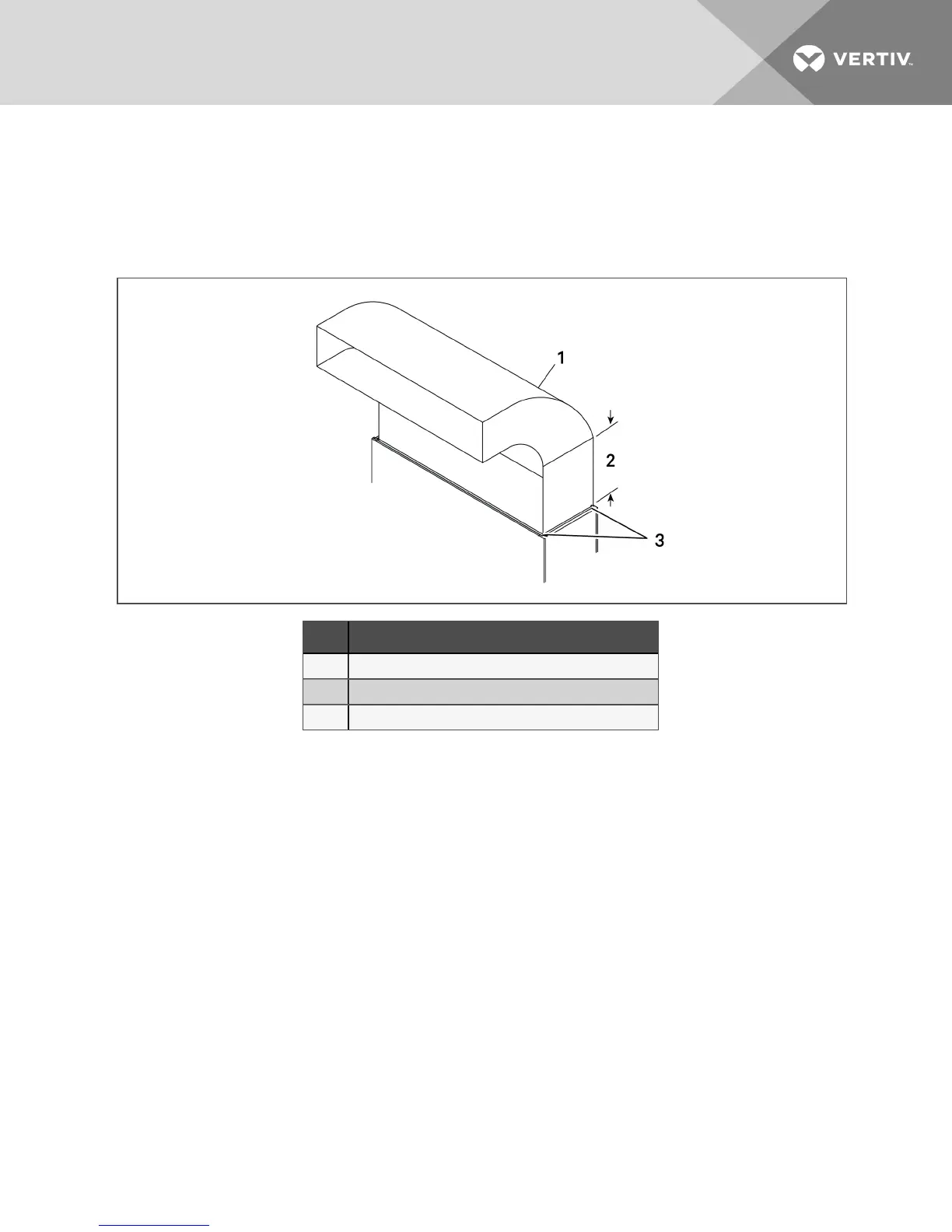

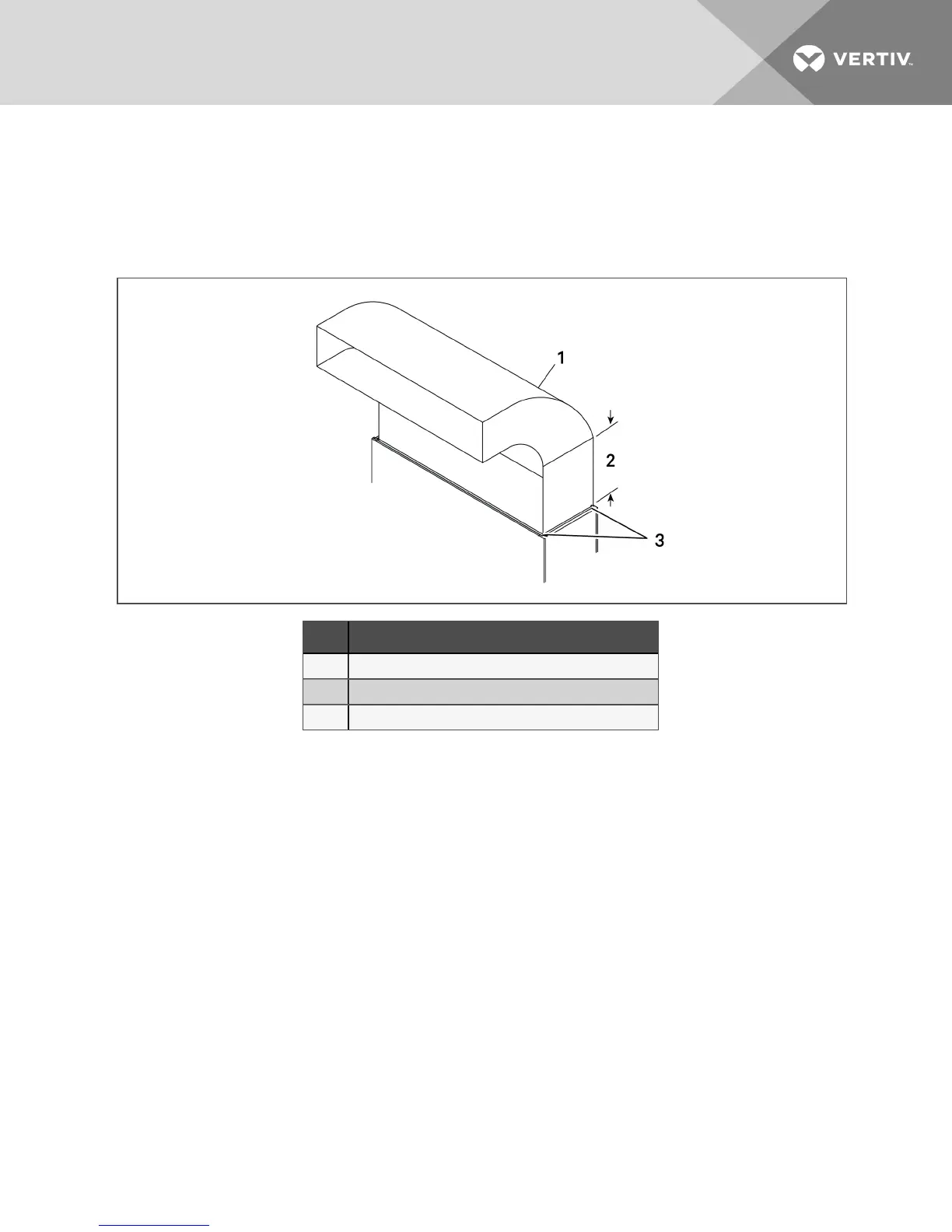

Figure 3.2 Upflow ducting configurations for EC fans for DA080 and DA085

Item Description

1 Typical ducting. May run to either side.

2 Straight section muse be 2.5 times the depth of blower.

3 Ducting only attached to flanges onprovidedplenum.

NOTE: Follow standard practices in all ductwork.

3.4 Connections and System Setup

• The unit requires a drain, which must comply with all applicable codes. This drain line may

contain boiling water. See Field-installed, Gravity-fed Drain Line Requirements on page32, for

details.

• Three-phase electrical service is required for all models. Electrical service must conform to

national and local electrical codes. See equipment nameplate for details.

• Plan the routing of wiring, piping and ductwork to the unit. Refer to the appropriate piping

connection location drawings, piping schematics, and electrical-connection drawings for your

system in Submittal Drawings on page93.

• If seismic requirements apply, consult your Vertiv representative for information about a

seismic-rated floor stand.

NOTE: Seal openings around piping and electrical connection to prevent air leakage. Failure to do so

could reduce the unit’s cooling performance.

The DSE controls superheat with an electronic expansion valve (EEV). The EEV controller adjusts the

orifice based on suction pressure and temperature. The EEV control will drive the valve to maintain the

superheat setpoint, set in the Liebert® iCOM, using a Proportional, Integral, Derivative (PID) routine. The

PID control values are set at the factory for most applications. These default values PID will allow stable

superheat control of the unit.

3 Pre-installation PreparationandGuidelines 19

Loading...

Loading...