10.6 Electronic Expansion Valve (EEV) Maintenance

The EEV controls superheat through the Liebert® iCOM™ controls by actively measuring suction

pressure via a transducer attached to the suction-line rotalock and suction temperature via a thermister

strapped to the suction line. The EEV actively adjusts the orifice size and resulting mass flow of refrigerant

to maintain the superheat setpoint (set in Liebert® iCOM). The EEV is used in place of the standard

thermal expansion valve (TXV).

WARNING! Risk of electric shock. Can cause serious injury or death. The Liebert® iCOM

microprocessor does not isolate power from the unit, even in the "Unit Off" mode. Some internal

components require and receive power even during the "unit off" mode of the Liebert® iCOM

control. Open all local and remote electric power disconnect switches and verify with a

voltmeter that power is Off before working on any component of the system.

NOTE: Intermittent loss of subcooling may result in EEV/superheat instability. If superheat instability is

observed, check for proper refrigerant level in receiver (see Refrigerant Piping Guidelines

forAir-cooledSystems on page35 for the proper charge level). If proper charge is observed in receiver,

and superheat remains unstable, then increase superheat setting in the Liebert® iCOM to 15°F (8.49°C).

10.7 Compressor Maintenance

10.7.1 Compressor Oil

NOTICE

Risk of improper compressor lubrication. Can cause compressor and refrigerant system

damage.

Failure to use oil types, viscosities and quantities recommended by the compressor

manufacturer may reduce compressor life and void the compressor warranty.

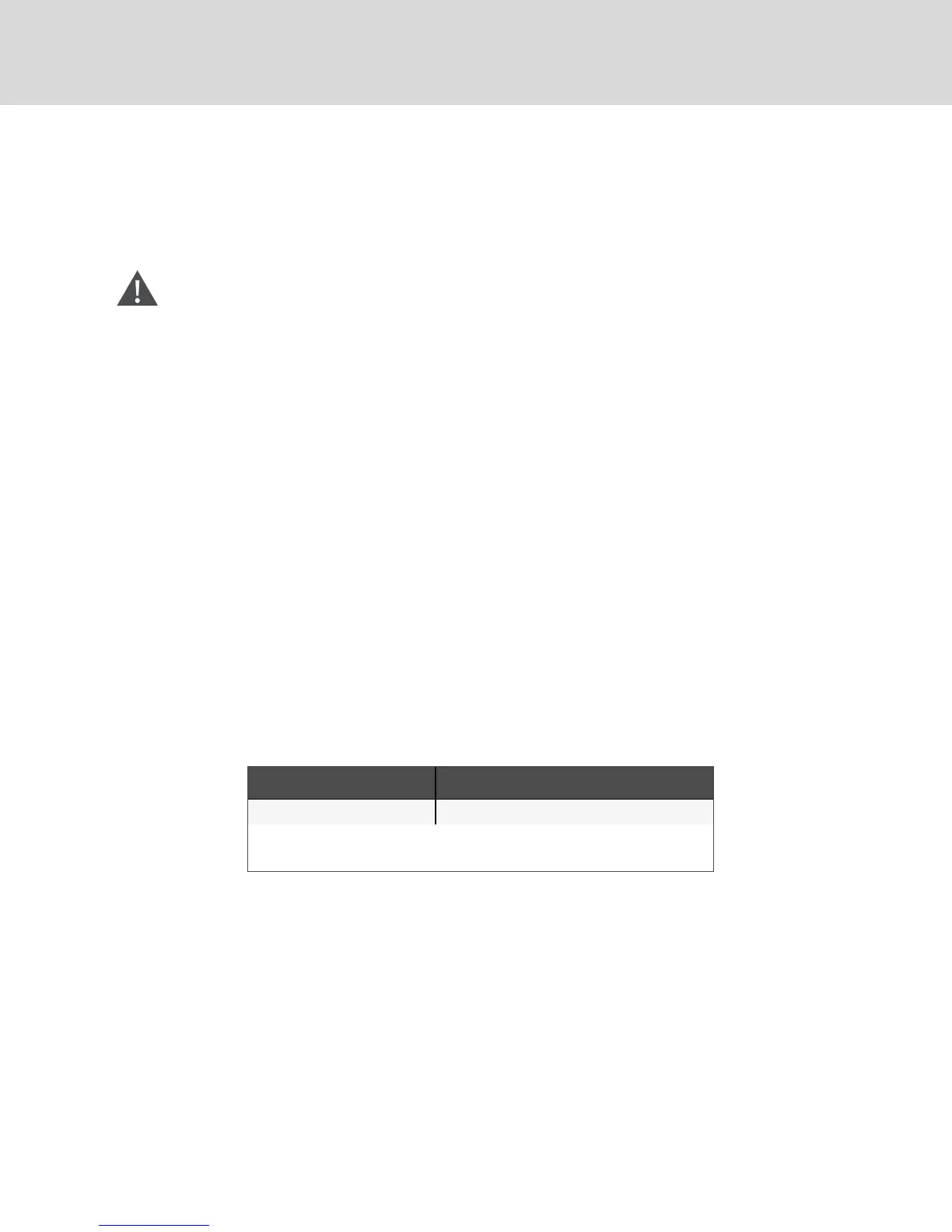

See oil types specified in Table 10.3 below.

• Do not mix polyolester (POE) and mineral-based oils.

• Do not mix oils of different viscosities.

• Consult Vertiv technical support or the compressor manufacturer if questions arise.

Compressor Type Oil Type

Copeland Scroll and Digital Scroll POE Oil - ISO 32 Centistoke Viscosity

1

1. Use Copeland POE Oil ULTRA 32-3MAF or other Copeland-approved oils.

Source: DPN003950. Rev.5

Table 10.3 Compressor oil types for R-410A Refrigerant

NOTE: See Additional Oil Requirements forScrollandDigital-scrollCompressors on page38 for

additional oil based on the system's refrigerant charge.

Vertiv | Liebert® DSE™ Installer/User Guide

70

Loading...

Loading...