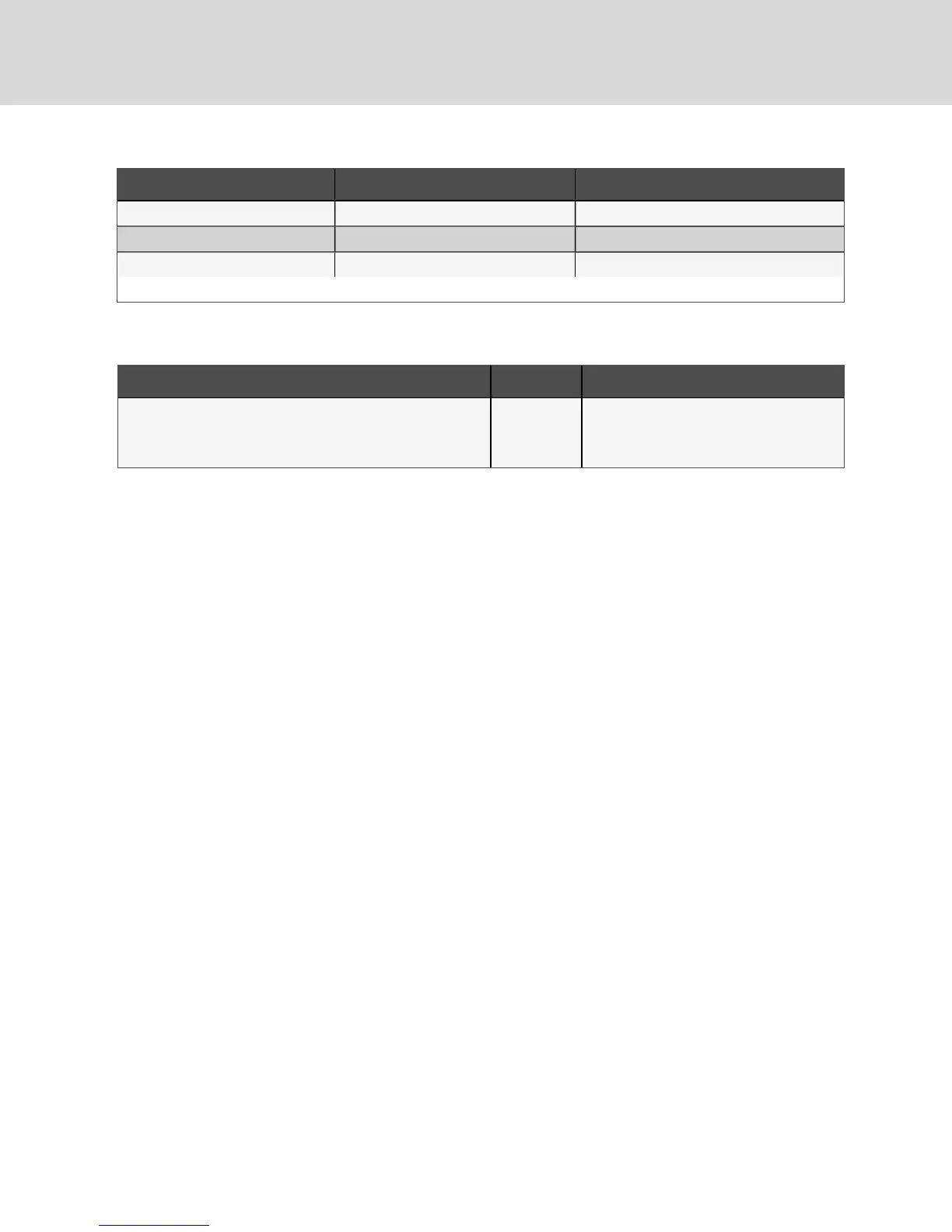

Line Size, O.D., in. Liquid Line Hot Gas Line

7/8 19.8 (9.1) 2.3 (1.0)

1-1/8 33.8 (15.5) 3.9 (1.8)

1-3/8 51.5 (23.5) 5.9 (2.7)

Source: DPN003099, Rev. 1

Table 5.7 Interconnecting Piping Refrigerant Charge for R-410A, lb per 100ft (kg per 30m)

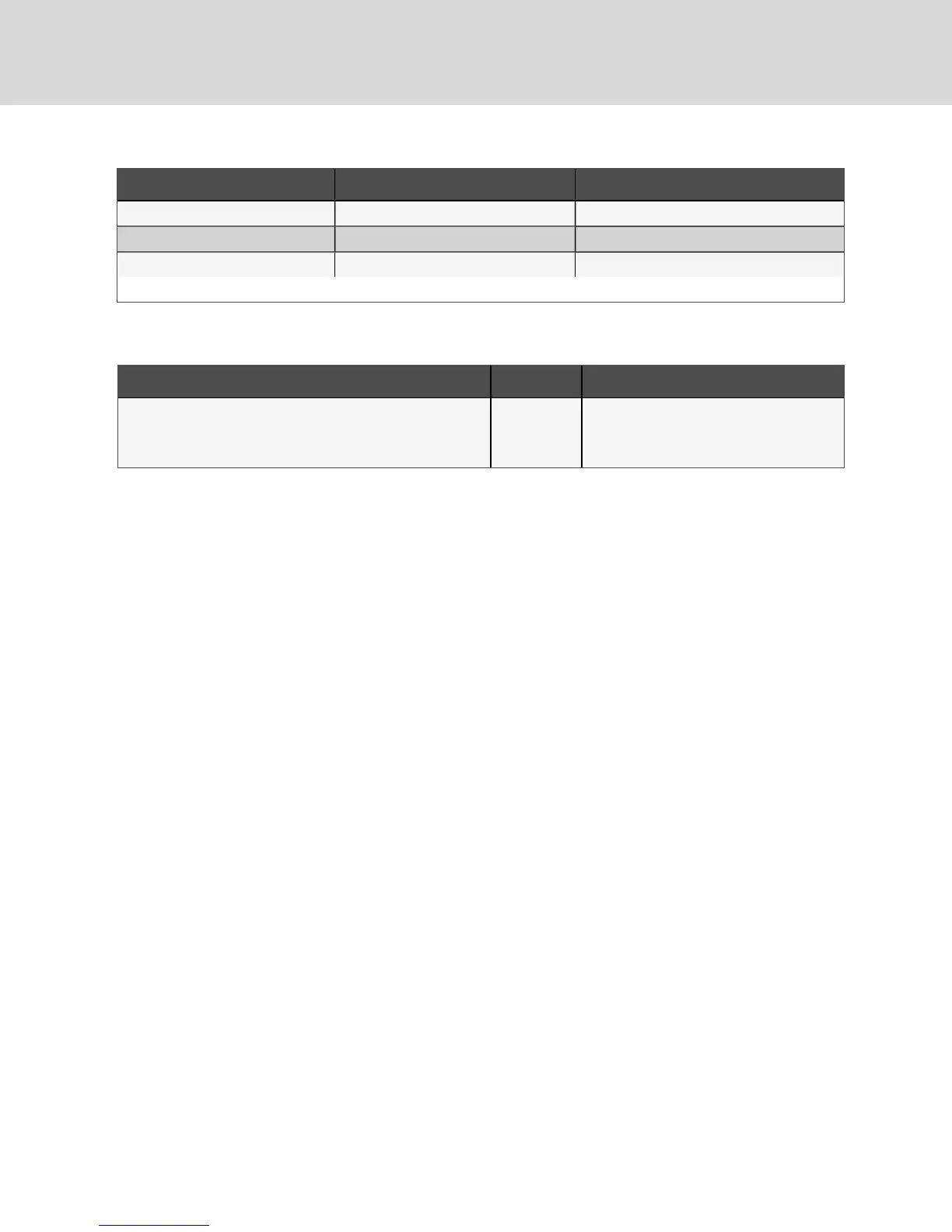

System Type Model Charge per Circuit, lb(kg)

Liebert® EconoPhase™ Pumping Unit

PR125

PR085

PR050

5.4 (2.5)

Table 5.8 Liebert Pump Module Refrigerant Charge forR-410APer Circuit

5.2.4 Additional Oil Requirements forScrollandDigital-scrollCompressors

NOTICE

Risk of improper compressor lubrication. Can cause compressor and refrigerant system

damage.

Failure to use oil types, viscosities and quantities recommended by the compressor

manufacturer may reduce compressor life and void the compressor warranty. See Table 10.3

on page70 for the recommended oil for the system.

• Do not mix polyolester (POE) and mineral-based oils.

• Do not mix oils of different viscosities.

• Consult your local sales representative, Vertiv product support at 1-800-543-2778, or the

compressor manufacturer if questions arise.

See Table 5.9 on the facing page, for the amount required for various system charge levels.

In addition to oil added based on system charge, additional oil is required for discharge-line field-installed

traps. Standard-formed tube traps are required, see Figure 5.2 on the facing page and Table 5.10 on

page40, because straight tubes and fittings used as traps require much more oil and the length of the

straight tube can vary.

After the system has been fully charged with refrigerant, use a hand pump to add the additional oil at the

suction side of the system while the system is running.

The amount of oil added by field service must be recorded on the tag marked “Oil Added Field Service

Record,” attached to each compressor. The date of oil addition must be included as well.

Vertiv | Liebert® DSE™ Installer/User Guide

38

Loading...

Loading...