19

1. Remove the hinges and store them in case they

need to be reinstalled at a later date.

4. Pull the plug of the connecting cable from the

bracket.

!

Please note

Incorrect routing of the cable can lead to

heat damage and impairment of the EMC

properties.

Do not change the position of the cable or its

fixture (fixing point on casing).

6. Turn the bracket over and insert the plug on the

right-hand side again.

Connections on the heating water and DHW sides

If the connections have not been fitted previously,

make the connections on the heating water and DHW

sides.

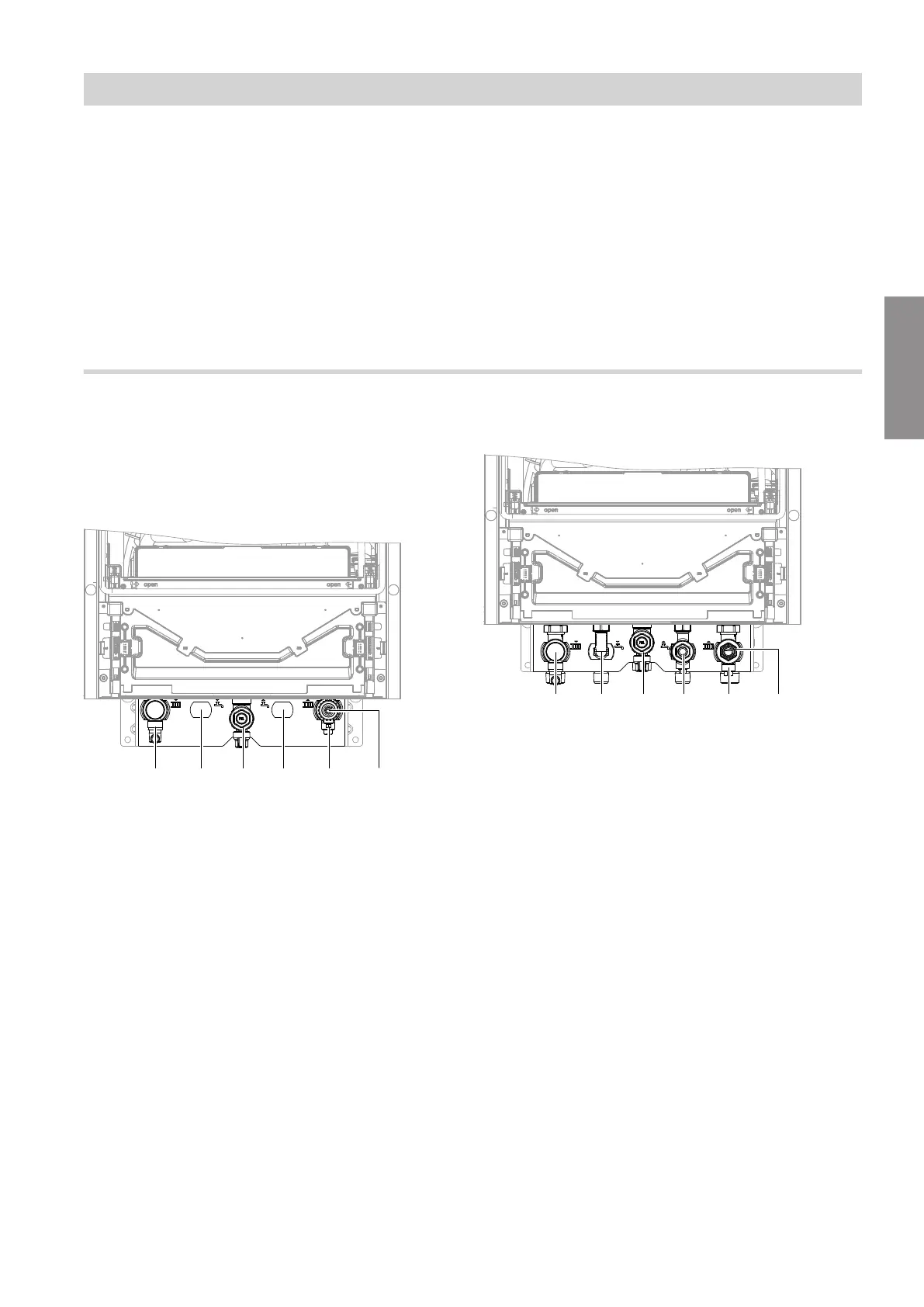

Gas condensing system boiler

Fig. 8 Specifications for threads in conjunction with

connection accessories

A

Heating flow R ¾ (male thread)

B

Cylinder flow G ¾ (male thread)

C

Gas connection R ¾ (male thread)

D

Cylinder return G ¾ (male thread)

E

Heating return R ¾ (male thread)

F

Filling/draining

Connection on the heating water side of the DHW

cylinder:

The required intermediate pieces (Rp ¾, female

thread) on the cylinder flow and return are part of the

connection set for the DHW cylinder.

If no DHW cylinder is being connected, seal off the

connections with caps.

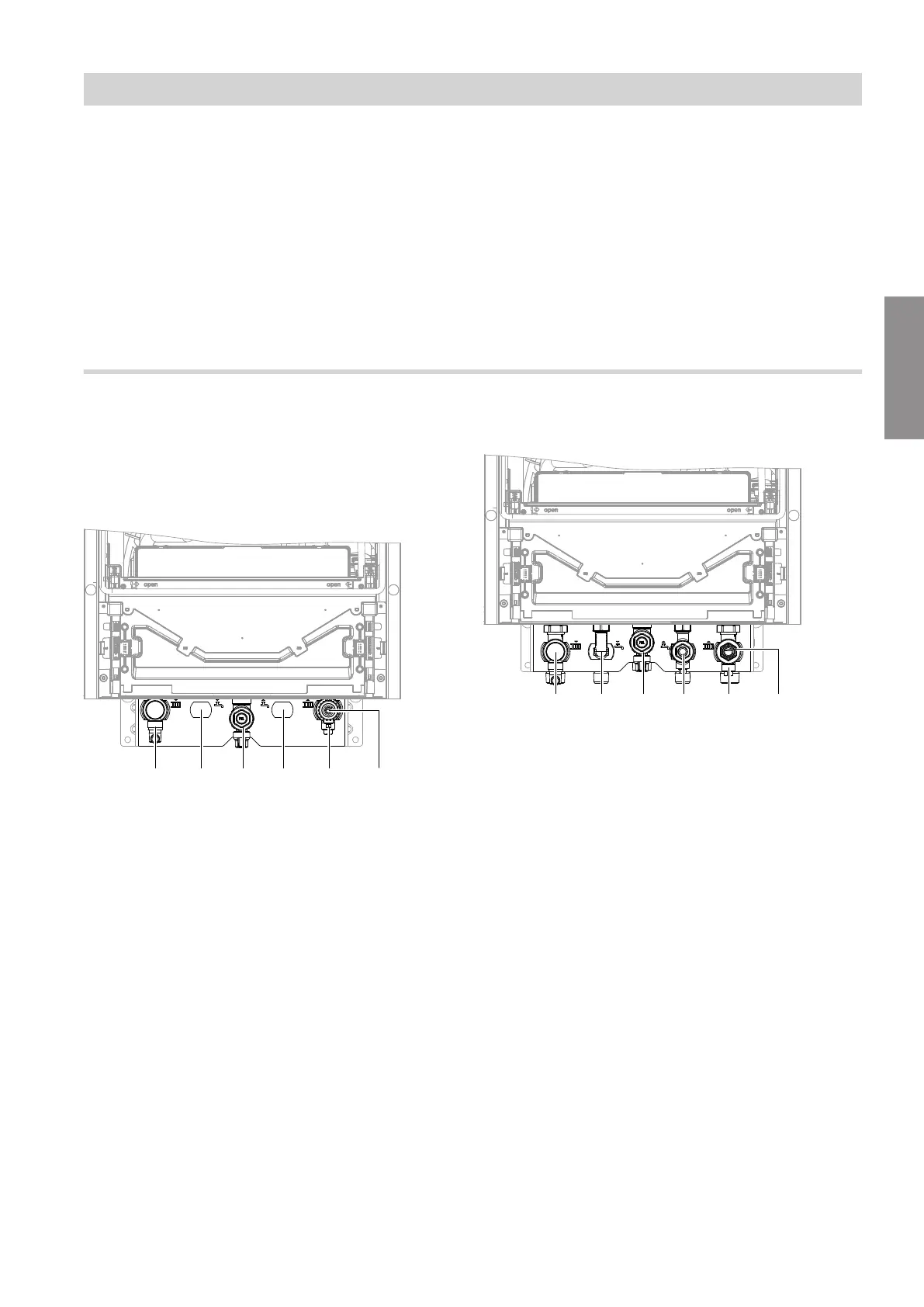

Gas condensing combi boiler

Fig. 9 Specifications for threads in conjunction with

connection accessories

A

Heating flow R ¾ (male thread)

B

DHW R ½ (male thread)

C

Gas connection R ¾ (male thread)

D

Cold water R ½ (male thread)

E

Heating return R ¾ (male thread)

F

Filling/draining

Scald protection

DHW temperatures of over 60 °C can occur with gas

condensing combi boilers. As a result, scald protection

should be installed on site in the DHW pipe.

Installation sequence

Mounting the boiler and making connections (cont.)

5593201

Installation

Loading...

Loading...