52

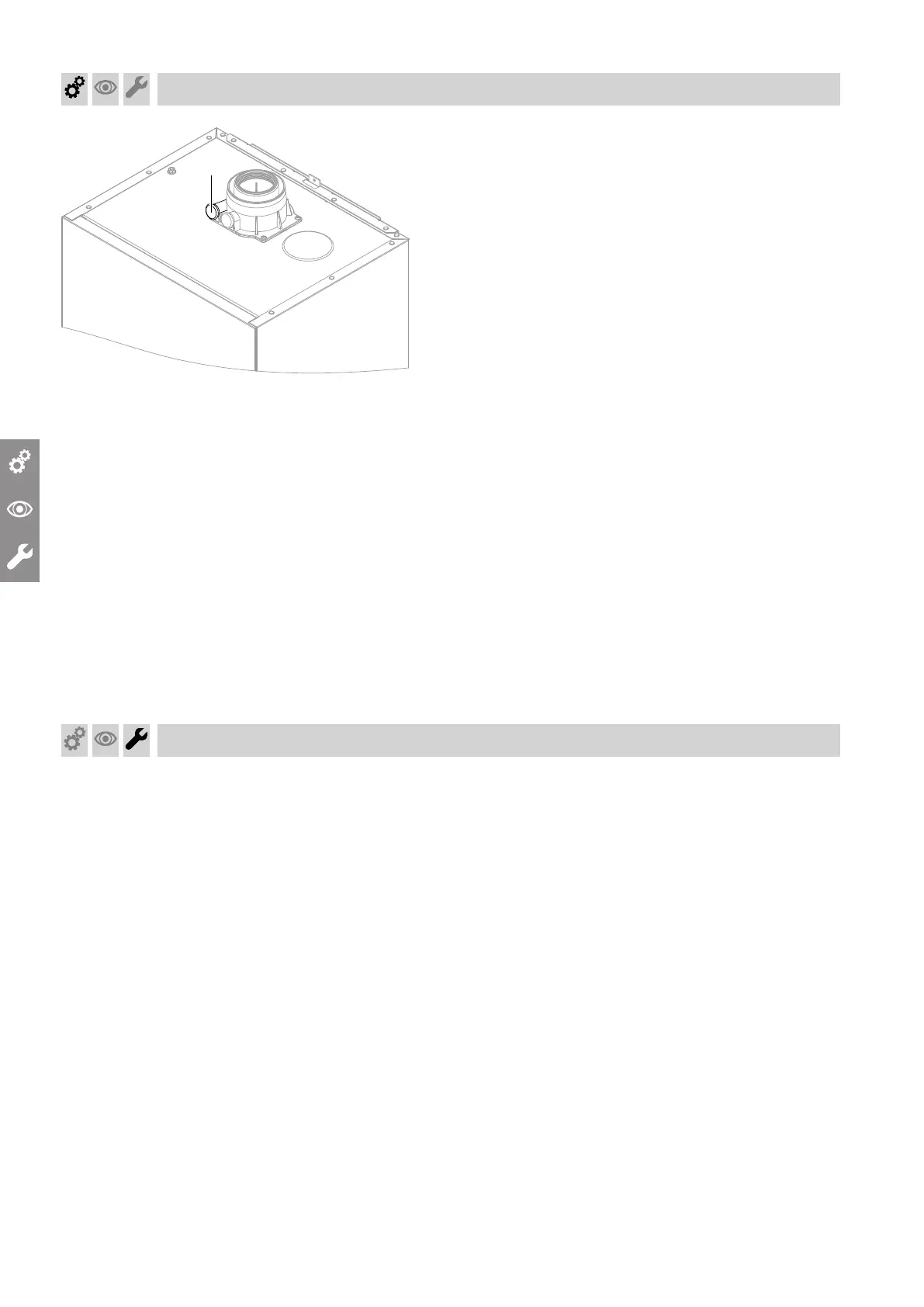

Fig. 37

A

Combustion air aperture

For balanced flue systems tested together with the

heat generator, there is no requirement for a tightness

test (overpressure test) during commissioning by the

flue gas inspector.

In this case, we recommend that a simple tightness

test is carried out during system commissioning. For

this, check the CO

2

or O

2

concentration in the combus-

tion air at the annular gap of the balanced flue pipe.

If the CO

2

concentration is less than 0.2 % or the O

2

concentration is greater than 20.6 %, the flue pipe is

deemed to be sufficiently gas-tight.

If actual CO

2

values are greater or O

2

values are lower,

then pressure test the flue pipe with a static pressure

of 200 Pa.

!

Please note

If the test port is not sealed, combustion air is

drawn in from the room.

After the tightness test, re-seal the test port with

the plug.

Removing the burner

Note

If the programming unit is located at the top: Move the

programming unit down into the maintenance position.

See page 46.

Commissioning, inspection, maintenance

Leak test on balanced flue system (annular gap check)

5593201

Loading...

Loading...