47

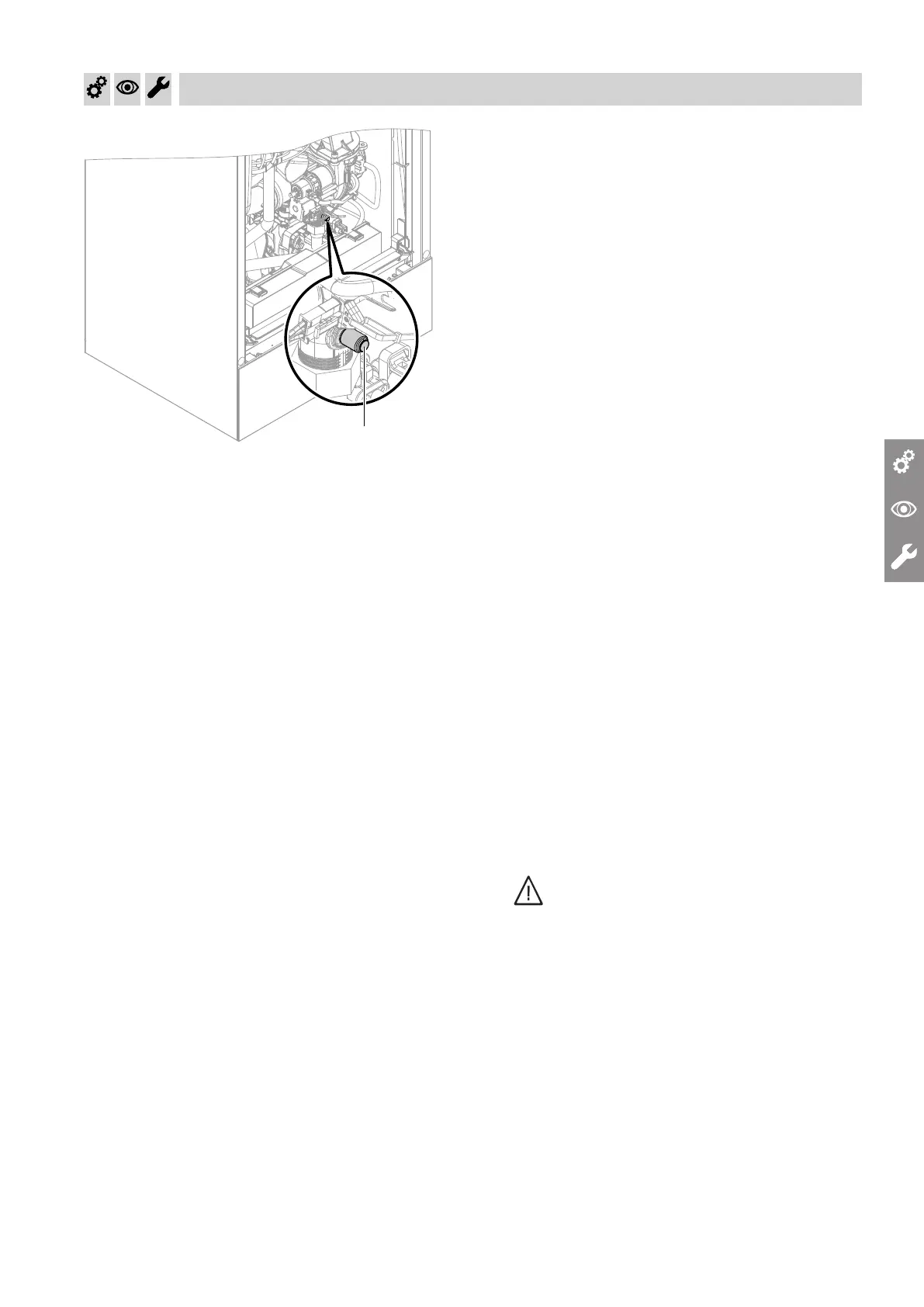

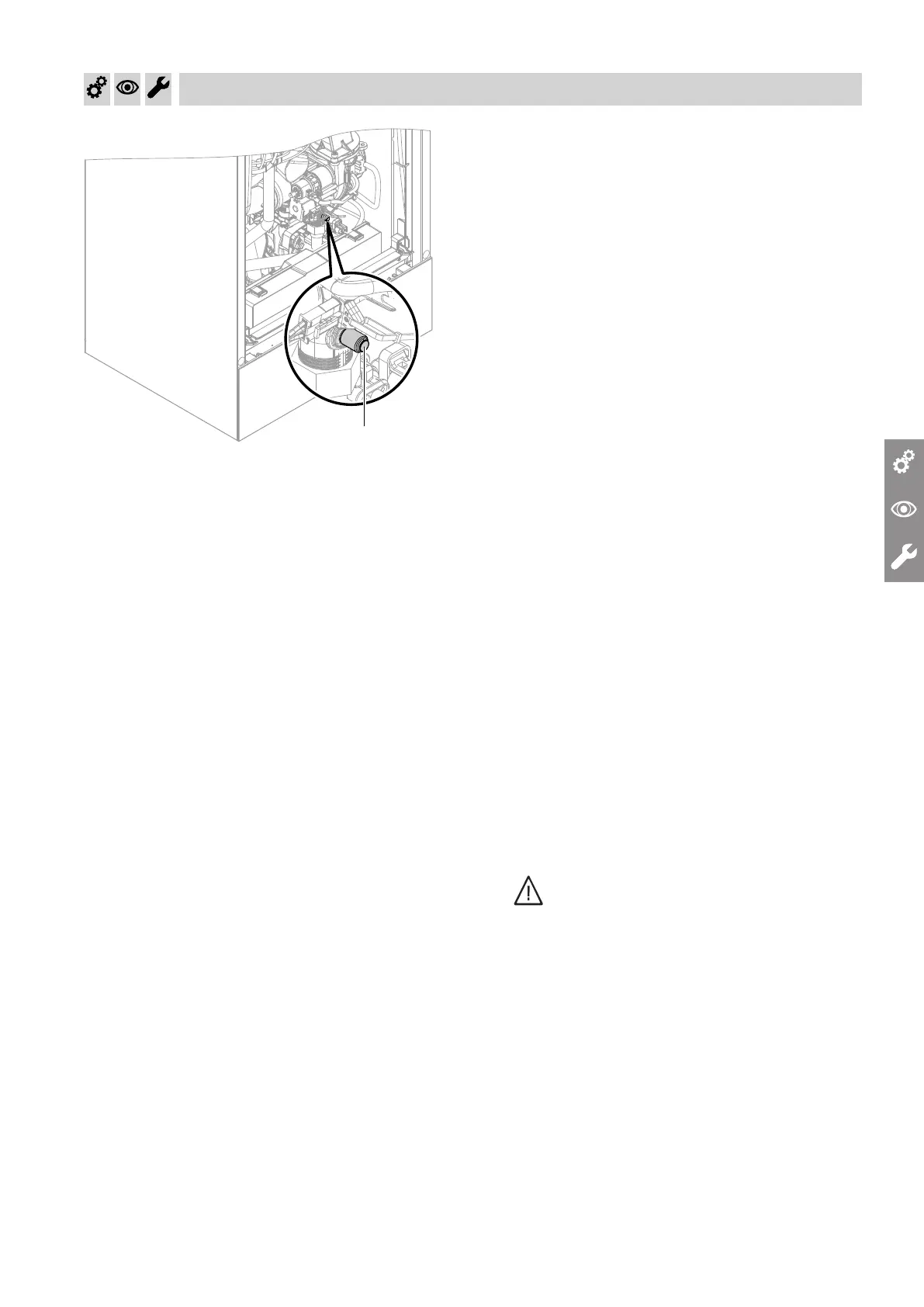

Fig. 34

01. Turn off the ON/OFF switch.

02. Close the gas shut-off valve.

03.

Undo screw

A

inside test connector on the gas

train, but do not remove it. Connect the pressure

gauge.

04. Open the gas shut-off valve.

05. Test the static pressure and record it in the report.

Set value: Max. 57.5 mbar (5.75 kPa).

06. Turn on the ON/OFF switch and start the boiler.

Note

During commissioning, the appliance can enter a

fault state if there are airlocks in the gas line.

Reset the appliance after approx. 5 s (see operat-

ing instructions).

07. Check the supply (flow) pressure. For set values,

see the following table.

Note

Use a suitable measuring device with a resolution

of at least 0.1 mbar (0.01 kPa) to check the supply

pressure.

08. Record the actual value in the report.

Implement measures as indicated in the table

below.

09. Shut down the boiler. Close the gas shut-off valve.

Remove the pressure gauge. Close test connector

A

with the screw.

10. Open the gas shut-off valve and start the appli-

ance.

Danger

Gas escaping from the test connector leads

to a risk of explosion.

Check gas tightness at test connector

A

.

11. Fit front panel (see installation sequence).

Commissioning, inspection, maintenance

Checking the static pressure and supply pressure (cont.)

5593201

Loading...

Loading...