Vibration System and Steering RD 12 / RD 12A

wc_tx000668gb.fm 58

6.2 Troubleshooting a System that Vibrates Poorly

Prerequisites 3000-psi pressure gauge

Compactible surface such as a bed of gravel or old tires

Background The exciter pump is designed to put out a constant flow of oil at a set engine speed.

This ensures that the vibration frequency remains steady. When troubleshooting

the exciter circuit, the vibration speed, operating pressure, and relief pressures

must be known to help determine the cause of any problems.

Procedure To measure vibration speed:

1. Start the machine and run it for several minutes to bring the hydraulic fluid up to

normal operating temperature.

2. Drive the machine onto a compactible surface such as a bed of gravel or old

tires.

3. Run the machine at full throttle. Check the engine RPM using a tachometer or

vibrotach. The engine must be running at the correct RPM to accurately mea-

sure vibration.

4. Start vibration. Hold the vibrotach (P/N 53397) against the outer rim of the drum

and measure the vibration speed.

5. Shut down the machine.

To check vibration system operating pressure:

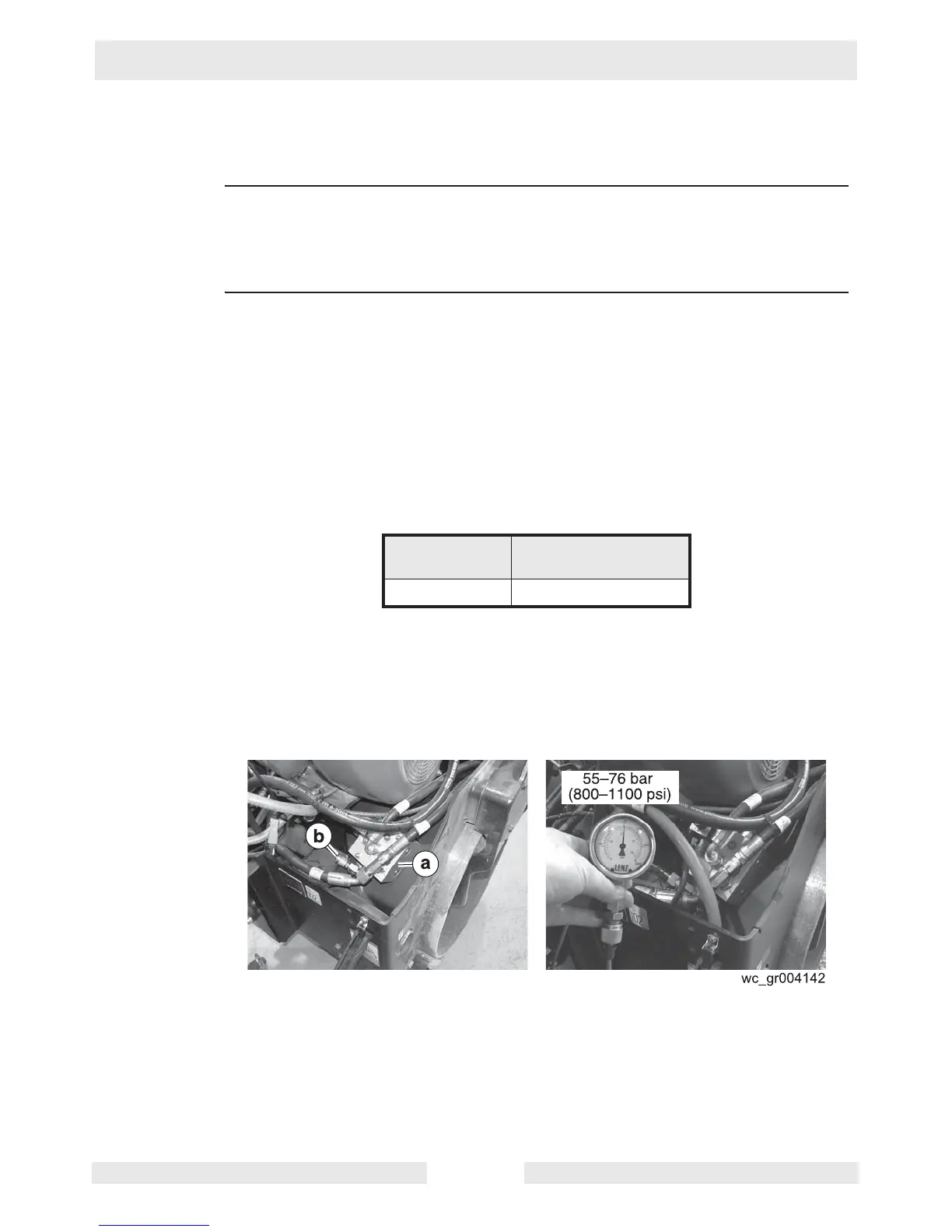

1. Open the engine compartment.

2. Locate the exciter solenoid valve

(a).

3. Connect a 3000-psi gauge to the test port

(b).

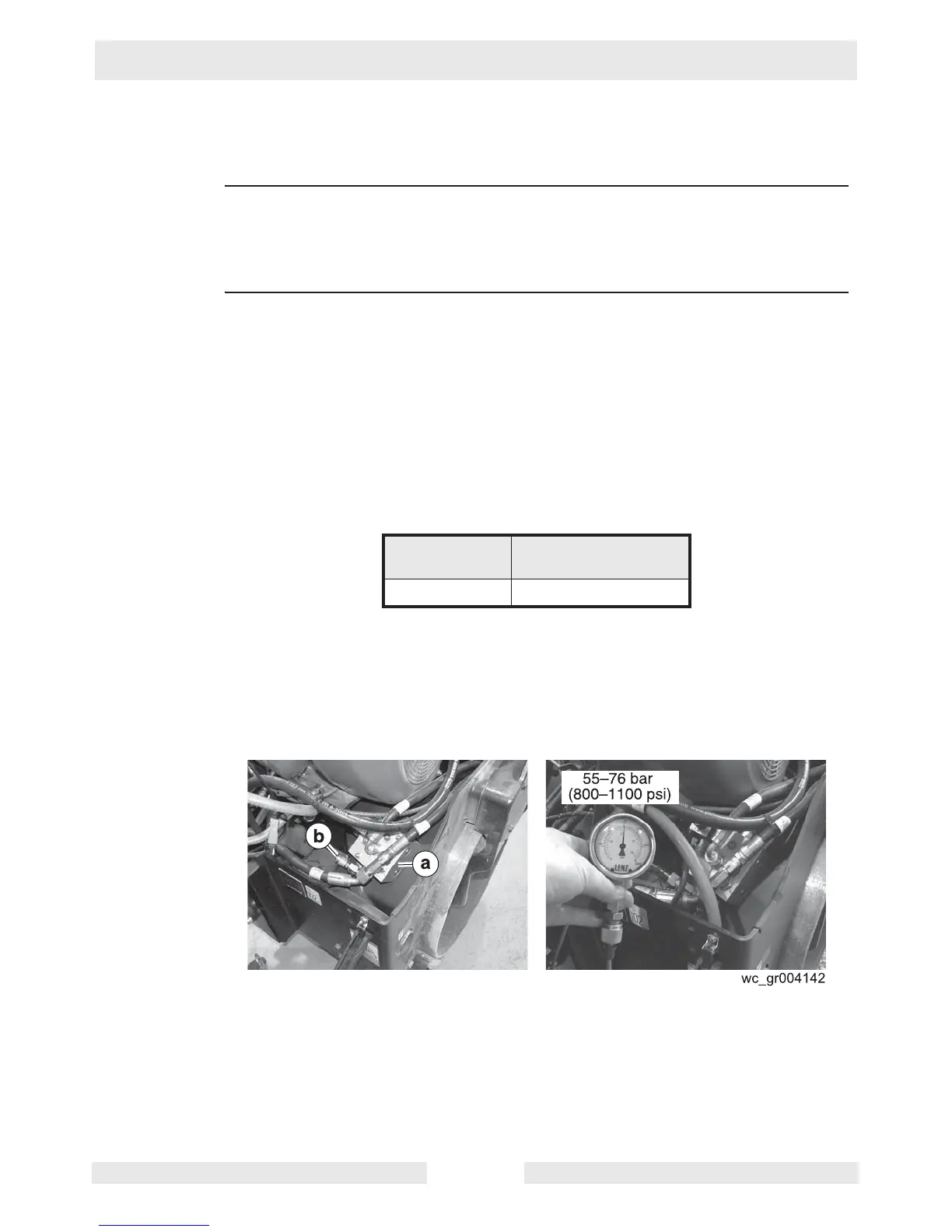

4. Start the engine and run the machine at full throttle.

This procedure continues on the next page.

Engine RPM Vibration Frequency

VPM

3100 4200

Loading...

Loading...