8. Cleaning the unit (shutting down)

A clean state is the best method of ensuring operation without

problems.Afteryouhavenishedspraying,cleantheunit.Underno

circumstances may any remaining coating material dry and harden in

the unit.

The cleaning agent used for cleaning (only with an igni tion point

above21°C)mustbesuitableforthecoatingmaterialused.

• Secure the spray gun, refer to the operating manual of the

spray gun.

Clean and remove tip.

For a standard tip, refer to Page 18, Section 12.2.

If a non-standard tip is installed, proceed according to the relevant

operating manual.

1. Remove suction hose from the coating material.

2. Closethereliefvalve,valvepositionSPRAY(p spray).

3. Switch the unit ON.

The container must be earthed in case of coating

materials which contain solvents.

Caution! Do not pump or spray into a container with

a small opening (bunghole)!

Refer to the safety regulations.

4. Pull the trigger of the spray gun in order to pump the

remaining coating material from the suction hose, high-

pressure hose and the spray gun into an open container.

5. Immerse suction hose with return hose into a container with a

suitable cleaning agent.

6. Turn the pressure control knob counterclockwise to minimum

pressure.

7. Open the relief valve, valve position PRIME (k circulation).

8. Pump a suitable cleaning agent in the circuit for a few

minutes.

9. Closethereliefvalve,valvepositionSPRAY(p spray).

10. Pull the trigger of the spray gun.

11. Pump the remaining cleaning agent into an open container

until the unit is empty.

12. Switch the unit OFF.

8.1 Cleaning unit from outside

First of all pull out mains plug from socket.

Attention

Danger of short circult through penetrating water!

Never spray down the unit with high-pressure or

high-pressure steam cleaners.

Attention

Do not put the high-pressure hose into solvents.

Use only a wet cloth to wipe down the outside of the

hose.

Wipe down unit externally with a cloth which has been immersed in a

suitable cleaning agent.

ProSpray 3.20 9

GB

Cleaning the unit (shutting down)

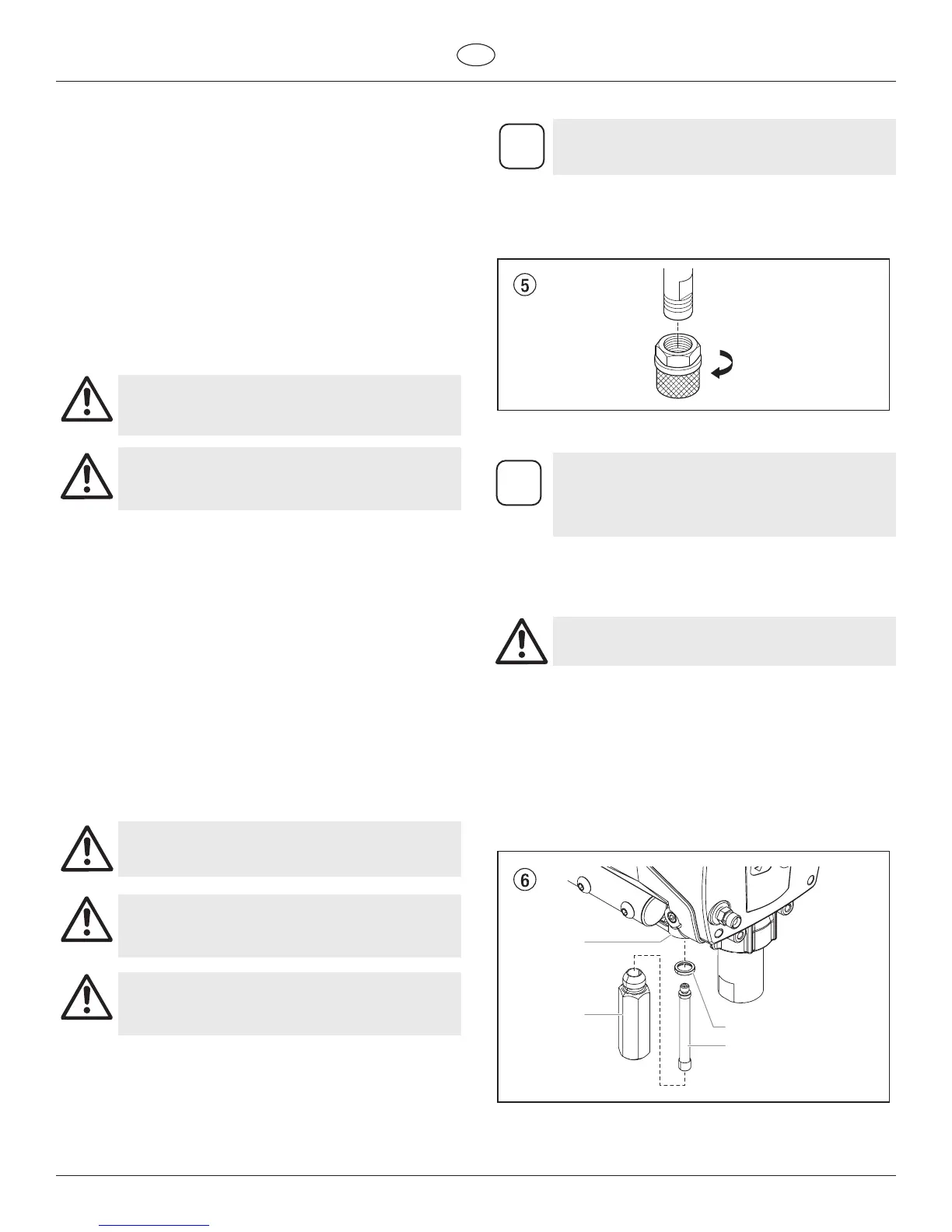

8.2 Suction lter

A clean suction lter always guarantees maximum

feed quantity, constant spraying pressure and

problem-free functioning of the unit.

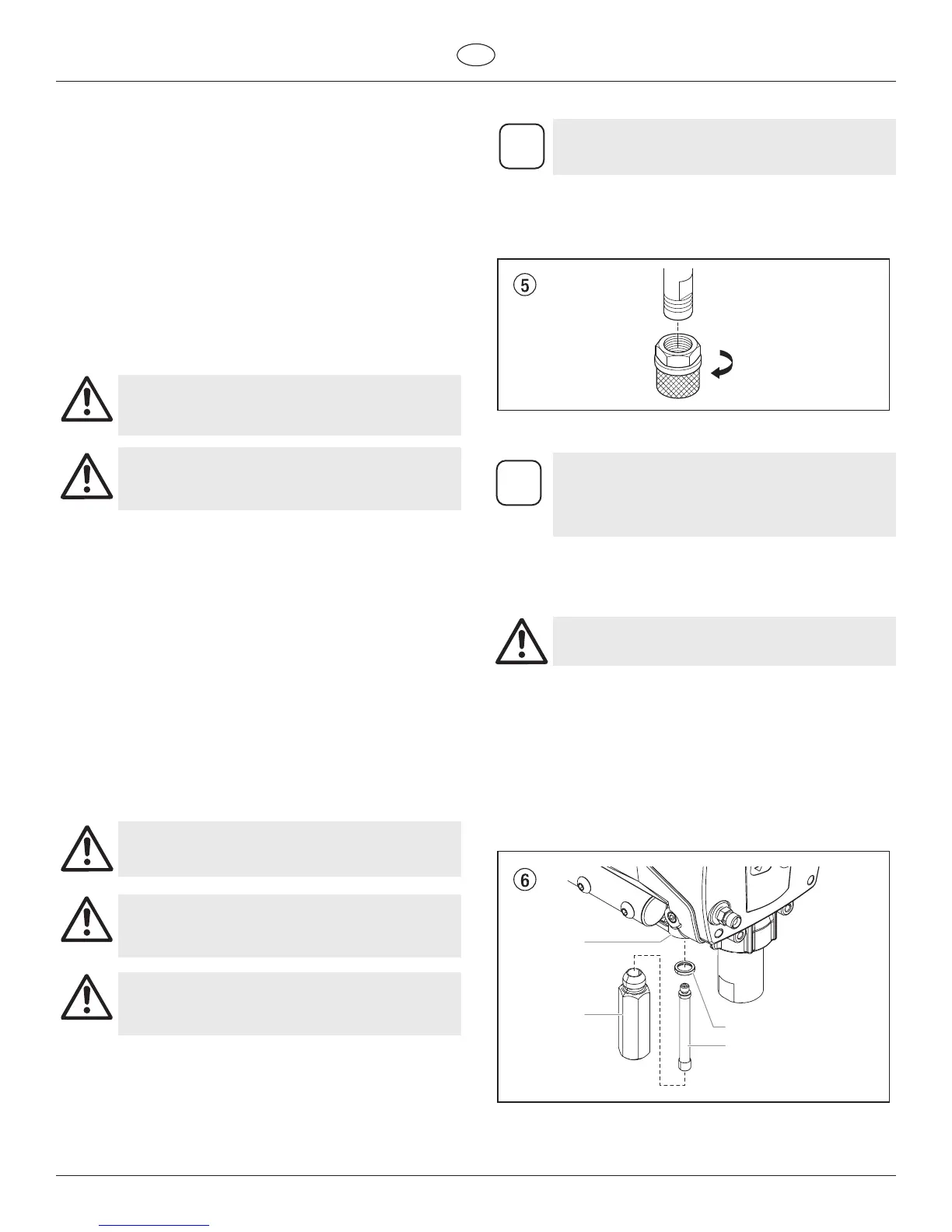

1. Screw o the lter (Fig. 5) from suction pipe.

2. Clean or replace the lter.

Carry out cleaning with a hard brush and an appropriate cleaning

agent.

8.3 Cleaning the high-pressure lter

i

A high-pressure lter is available as an optional

accessory that can be ordered separately. Clean the

lter cartridge regularly. A soiled or clogged high-

pressure lter can cause a poor spray pattern or a

clogged tip.

1. Turn the pressure control knob counterclockwise to minimum

pressure.

2. Open the relief valve, valve position PRIME (k circulation).

3. Switch the unit OFF.

Unplug the power plug from the outlet.

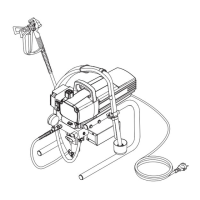

4. Unscrewthelterhousing(Fig.6,Item1)withastrapwrench.

5. Turning clockwise, unscrew the lter (2) from the pump

manifold (3).

6. Clean all the parts with the corresponding cleaning agent. If

necessary, replace the lter cartridge.

7. Check the O-ring (4), replace it if necessary.

8. Turning counterclockwise, screw the new or cleaned lter into

the pump manifold.

9. Screw in lter housing (1) and tighten it as far as possible with

the strap wrench.

1

3

2

4

Loading...

Loading...