9.3 External cooling water system

It is recommended to divide the engines into several circuits in multi-engine installations. One

reason is of course redundancy, but it is also easier to tune the individual flows in a smaller

system. Malfunction due to entrained gases, or loss of cooling water in case of large leaks

can also be limited. In some installations it can be desirable to separate the HT circuit from

the LT circuit with a heat exchanger.

The external system shall be designed so that flows, pressures and temperatures are close

to the nominal values in Technical data and the cooling water is properly de-aerated.

Pipes with galvanized inner surfaces are not allowed in the fresh water cooling system. Some

cooling water additives react with zinc, forming harmful sludge. Zinc also becomes nobler

than iron at elevated temperatures, which causes severe corrosion of engine components.

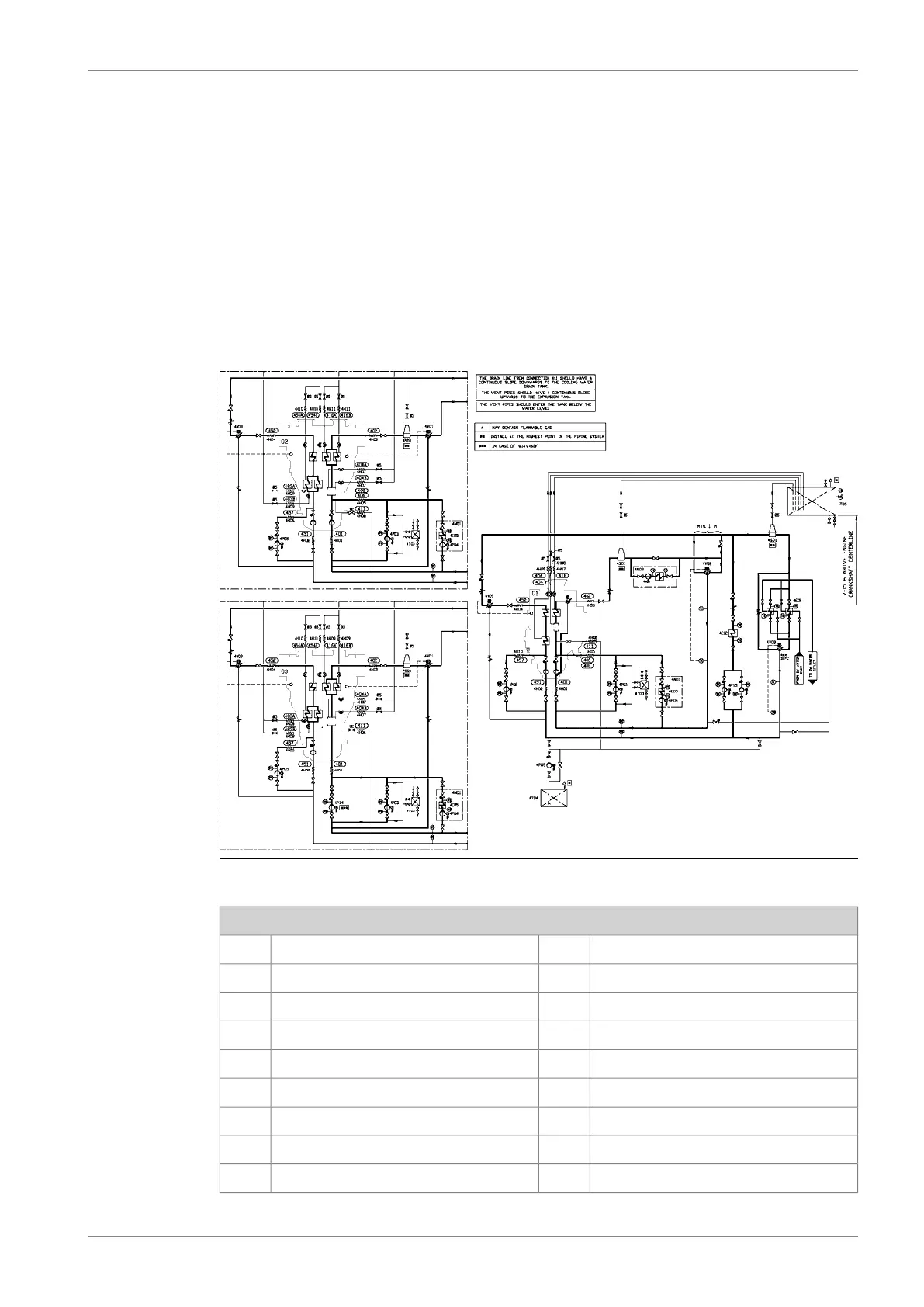

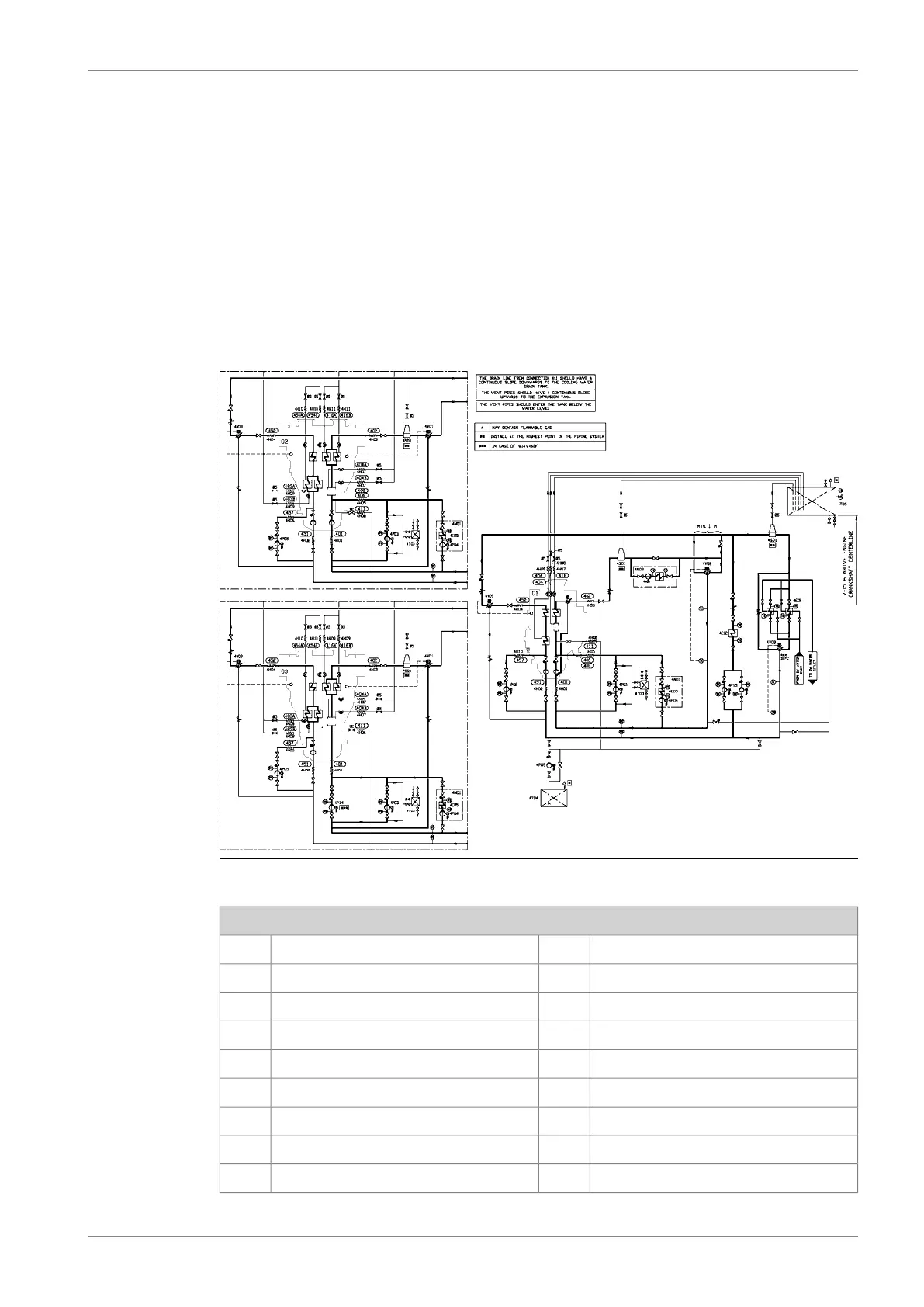

Fig 9-5 Cooling water system, single main engine combined LT/HT (DAAF418507)

System components:

Air venting4S01Heater (preheater)4E05

Additive dosing tank4T03Central cooler4E08

Drain tank4T04Cooler (Installation parts)4E12

Expansion tank4T05Preheating unit4N01

Temperature control valve (HT)4V01Evaporator unit4N02

Temp control valve (heat recovery)4V02Stand-by pump (LT)4P03

Temp control valve (central cooler)4V08Circulating pump (preheater)4P04

Temperature control valv (charge air)4V09Stand-by pump (LT)4P05

Transfer pump4P09

DBAD209883 9-7

9. Cooling Water SystemWärtsilä 46DF Product Guide

Loading...

Loading...