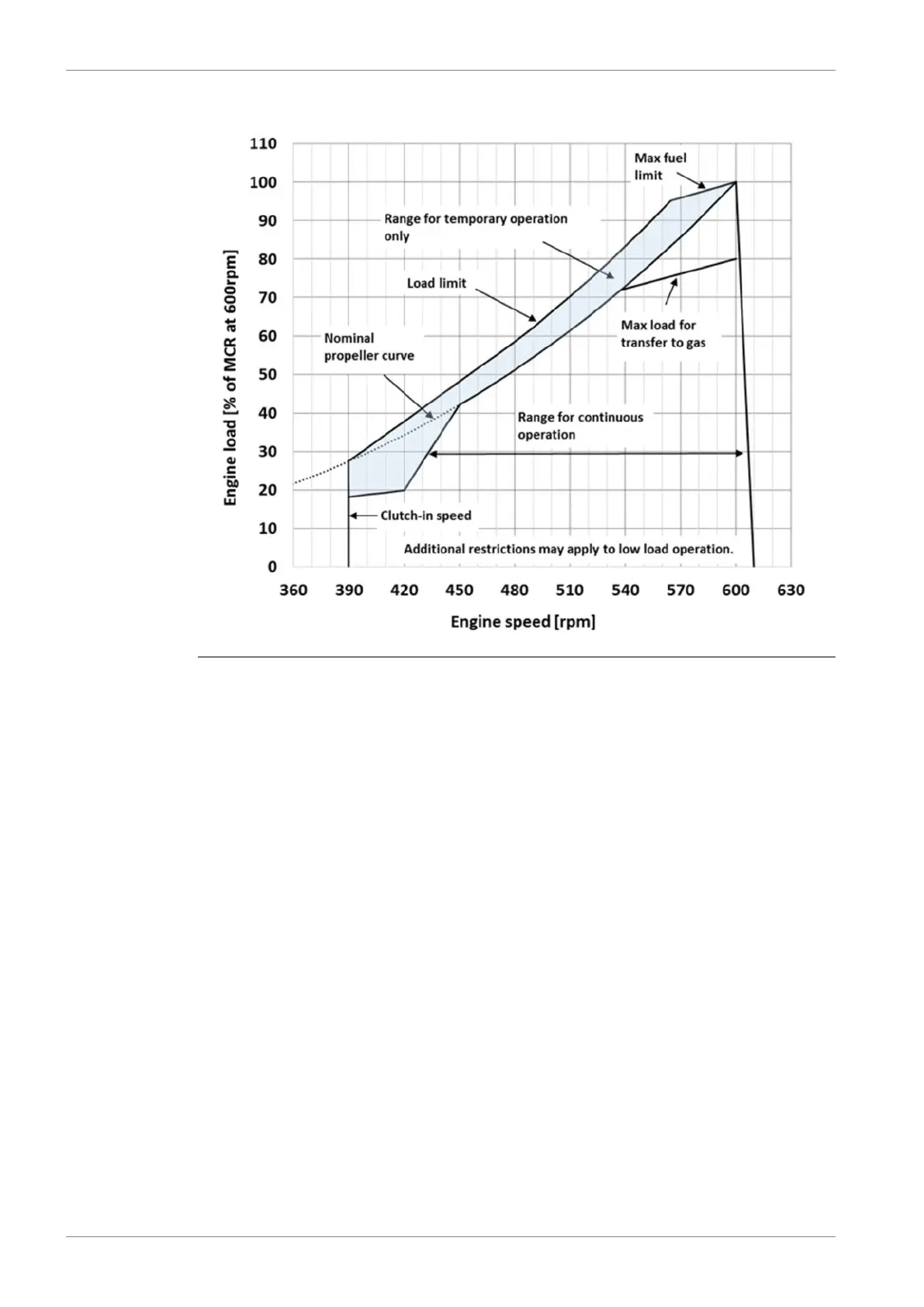

Fig 2-1 Operating field for CP Propeller, 1145 kW/cyl, 600 rpm

Remarks: The maximum output may have to be reduced depending on gas properties and

gas pressure. The permissible output will in such case be reduced with same percentage at

all revolution speeds.

Restrictions for low load operation to be observed.

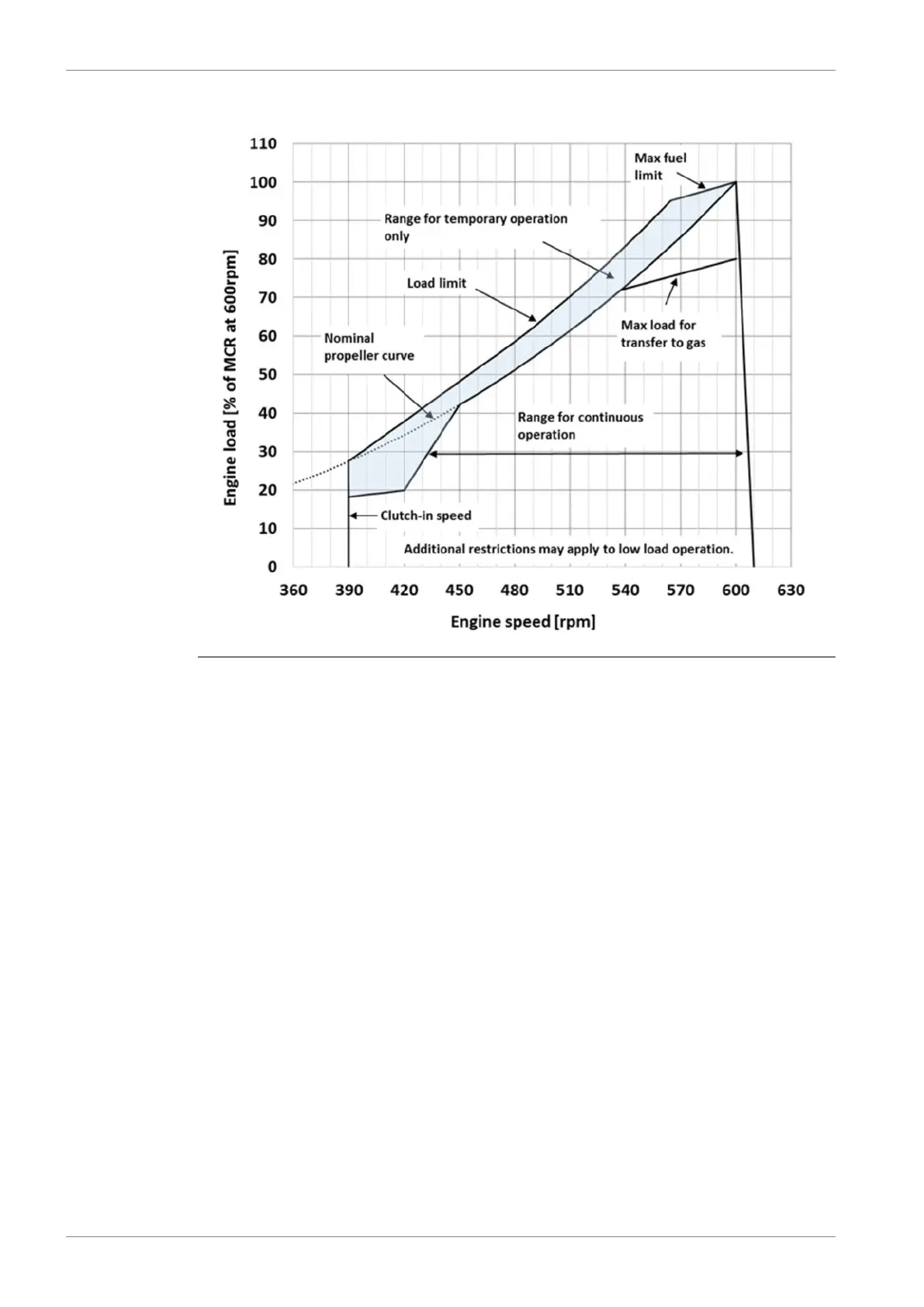

2.2 Loading capacity

Controlled load increase is essential for highly supercharged engines, because the turbocharger

needs time to accelerate before it can deliver the required amount of air. Sufficient time to

achieve even temperature distribution in engine components must also be ensured. Dual fuel

engines operating in gas mode require precise control of the air/fuel ratio, which makes

controlled load increase absolutely decisive for proper operation on gas fuel.

The loading ramp “preheated” (see figures) can be used as the default loading rate for both

diesel and gas mode. If the control system has only one load increase ramp, then the ramp

for a preheated engine must be used. The HT-water temperature in a preheated engine must

be at least 70ºC, and the lubricating oil temperature at least 40ºC.

The loading ramp “Normal operating temperature” can be taken into use when the engine has

been operating above 30% load for 6 minutes (or the cooling water temperature after cylinders

is min. 85ºC). All engines respond equally to a change in propulsion power (or total load), also

when a recently connected engine is still uploading to even load sharing with parallel engines.

A recently connected generator shall therefore not be taken into account as “available power”

until after 6 minutes, or alternatively the available power from this generator is ramped up to

100% during 10 minutes. If the control system has only one load increase ramp, then the ramp

for a preheated engine is to be used.

2-2 DBAD209883

Wärtsilä 46DF Product Guide2. Operating Ranges

Loading...

Loading...