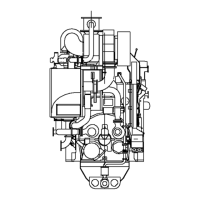

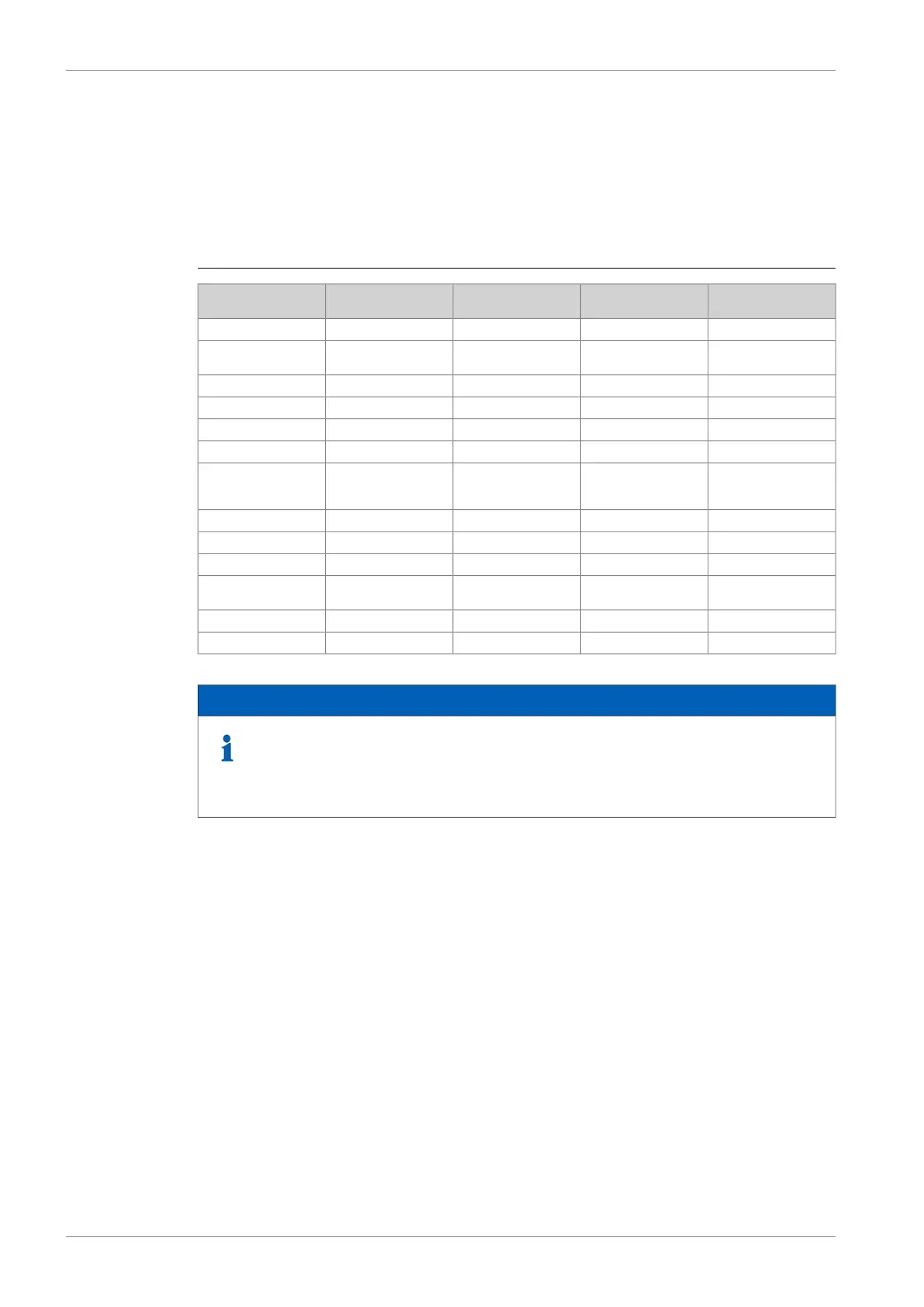

4.4 Overhaul inter vals and expected life times

The following component lifetimes are for guidance only. Actual figures will be different

depending on operating conditions, average loading of the engine, fuel quality used, fuel

handling system, performance of maintenance etc.

Expected component lifetimes have been adjusted to match with Time between overhaul data.

Table 4-1 Expected times between overhauls (TBO) and expected lifetimes (ELT)

Expected life time (h)

LFO/HFO operation

Maintenance interval (h)

LFO/HFO operation

Expected lifetime (h)

LFO/GAS operation

Maintenance interval (h)

LFO/GAS operation

Component

36000160003600020000- Big end bearing

6000012000 (HFO2)

16000 (HFO1)

60000...7200018000...20000- Cylinder head

1800001600018000024000- Cylinder liner

12000...1800012000...180003600012000...18000- Exhaust valve

320008000- Inj. valve complete ² ) ³)

8000800080008000- Injection nozzles ¹ )

2400012000 (HFO2)

16000 (HFO1)

--- Injection pump (Twin

Pump)

20000 (LFO)

24000240002400024000- Injection pump, pilot

2400012000...180003600012000...18000- Inlet valve

36000240003600024000- Main bearing

--1800018000- Main gas admission

valve

3600016000 ¹) / 24000 ²)12000024000 ¹) / 48000 ²)- Piston

16000160002400024000- Piston rings

NOTE

1) Inspection of one

2) Inspection of all

3) 3000 hours maintenance interval in the first installation required, Needle Operating

Pressure (NOP) test to be performed

4.5 Engine storage

At delivery the engine is provided with VCI coating and a tarpaulin. For storage longer than 3

months please contact Wärtsilä Finland Oy.

4-8 DBAD209883

Wärtsilä 46DF Product Guide4. Description of the Engine

Loading...

Loading...