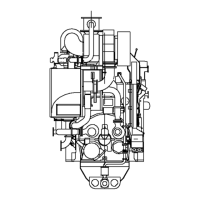

Wärtsilä 46DF engines are equipped with twin plunger pumps that enable control of the injection

timing. In addition to the timing control, the twin plunger solution also combines high mechanical

strength with cost efficient design.

One plunger controls the start of injection, i.e. the timing, while the other plunger controls

when the injection ends, thus the quantity of injected fuel. Timing is controlled according to

engine revolution speed and load level (also other options), while the quantity is controlled as

normally by the speed control.

4.2.11.3 Pilot fuel injection

The pilot fuel injection system is used to ignite the air-gas mixture in the cylinder when operating

the engine in gas mode. The pilot fuel injection system uses the same external fuel feed system

as the main fuel oil injection system.

The pilot fuel system comprises the following built-on equipment:

● Pilot fuel oil filter

● Common rail high pressure pump

● Common rail piping

● Twin fuel oil injection valve for each cylinder

The pilot fuel filter is a full flow duplex unit preventing impurities entering the pilot fuel system.

The fineness of the filter is 20 µm.

The high pressure pilot fuel pump is of engine driven type. The pilot fuel pump is mounted in

the free end of the engine. The delivered fuel pressure is controlled by the engine control

system and is approximately 100 MPa.

Pressurized pilot fuel is delivered from the pump unit into a small diameter common rail pipe.

The common rail pipe delivers pilot fuel to each injection valve and acts as a pressure

accumulator against pressure pulses. The high pressure piping is of double wall shielded type

and well protected inside the hot box. The feed pipes distribute the pilot fuel from the common

rail to the injection valves.

The pilot diesel injection part of the twin fuel oil injection valve has a needle actuated by a

solenoid, which is controlled by the engine control system. The pilot diesel fuel is admitted

through a high pressure connection screwed in the nozzle holder. When the engine runs in

diesel mode the pilot fuel injection is also in operation to keep the needle clean.

4.2.12 Lubricating oil system

The engine is equipped with a dry oil sump.

In the standard configuration the engine is also equipped with an engine driven lubricating oil

pump, located in free end, and a lubricating oil module located in the opposite end to the

turbocharger. The lubricating oil module consists of an oil cooler with temperature control

valves and an automatic filter. A centrifugal filter on the engine serves as an indication filter.

The pre-lubricating oil pump is to be installed in the external system.

4.2.13 Cooling water system

The fresh water cooling system is divided into a high temperature (HT) and a low temperature

(LT) circuit. The HT-water cools cylinder liners, cylinder heads and the first stage of the charge

air cooler. The LT-water cools the second stage of the charge air cooler and the lubricating

oil.

In the most complete configuration the HT and LT cooling water pumps are both engine driven,

and the electrically actuated temperature control valves are built on the engine. When desired,

it is however possible to configure the engine without engine driven LT-pump, or even without

both cooling water pumps.

4-4 DBAD209883

Wärtsilä 46DF Product Guide4. Description of the Engine

Loading...

Loading...